Spray gun

A spray gun and gun body technology, which is applied in the field of spray guns and can solve problems such as the inability to achieve positive spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

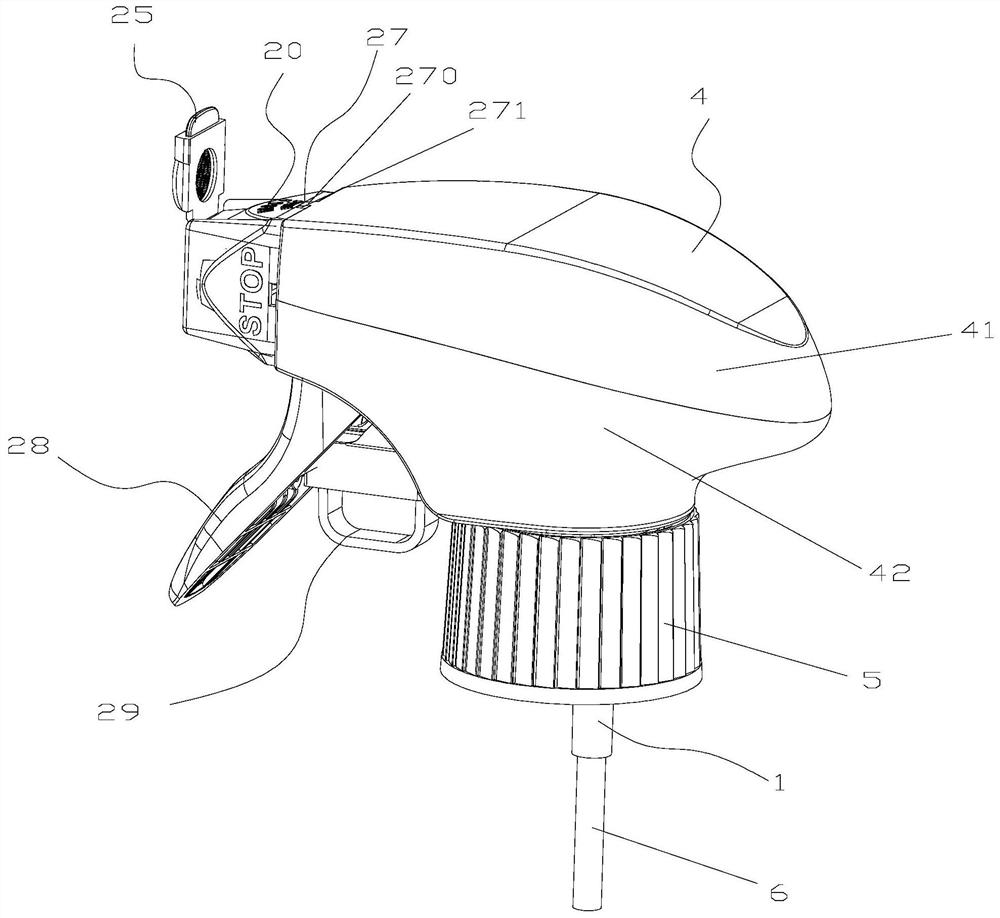

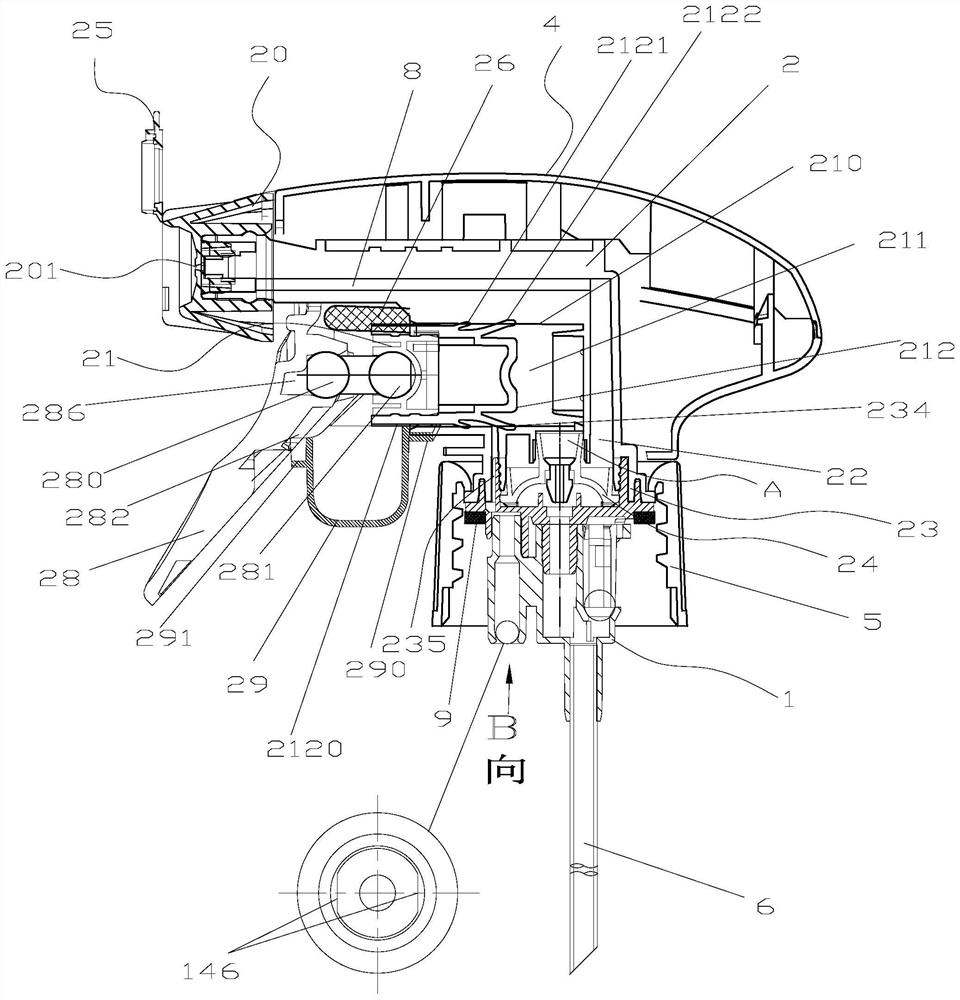

[0075] exist figure 1 , figure 2 In the illustrated embodiment, a spray gun comprising:

[0076] The gun body 2, the interior of the gun body is provided with a spray liquid channel 8 and a liquid pressure channel 22 which communicate with each other;

[0077] The nozzle part 20 is rotatably connected to the gun body 2 to open or close the liquid spray channel 8 and realize the spray or foam spray function;

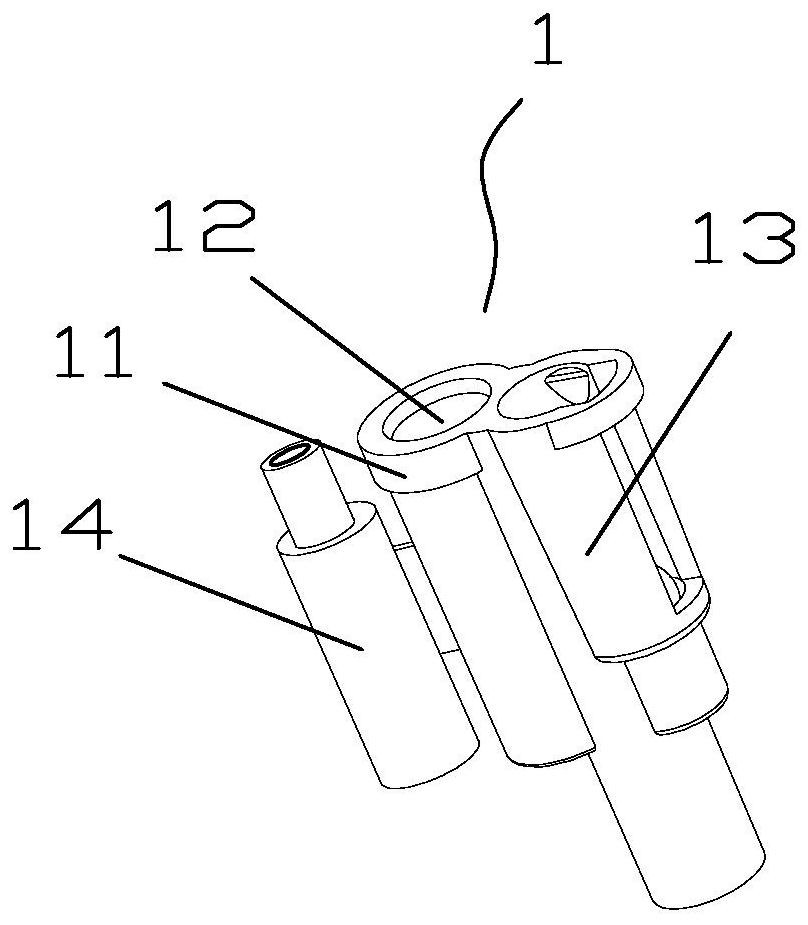

[0078] The pressure chamber part 21 is arranged on the gun body 2 and is arranged parallel to the liquid spray channel 8 below the liquid spray channel 8 to realize the air compression position; the pressure chamber part 21 includes a piston cylinder 210, a pressure chamber 211 and Piston 212, the piston 212 is slidingly sealed inside the pressure chamber 211 and realizes the suction action of the spray gun through the change of air pressure inside the pressure chamber 211; wherein, the piston 212 is located along the axis from the outside of the piston to the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com