Novel high-efficiency heat dissipation injection mold

An injection mold, high-efficiency technology, applied in the field of new high-efficiency heat dissipation injection molds, can solve the problems of prolonged demoulding period of finished products, low efficiency of injection molding process, poor heat dissipation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

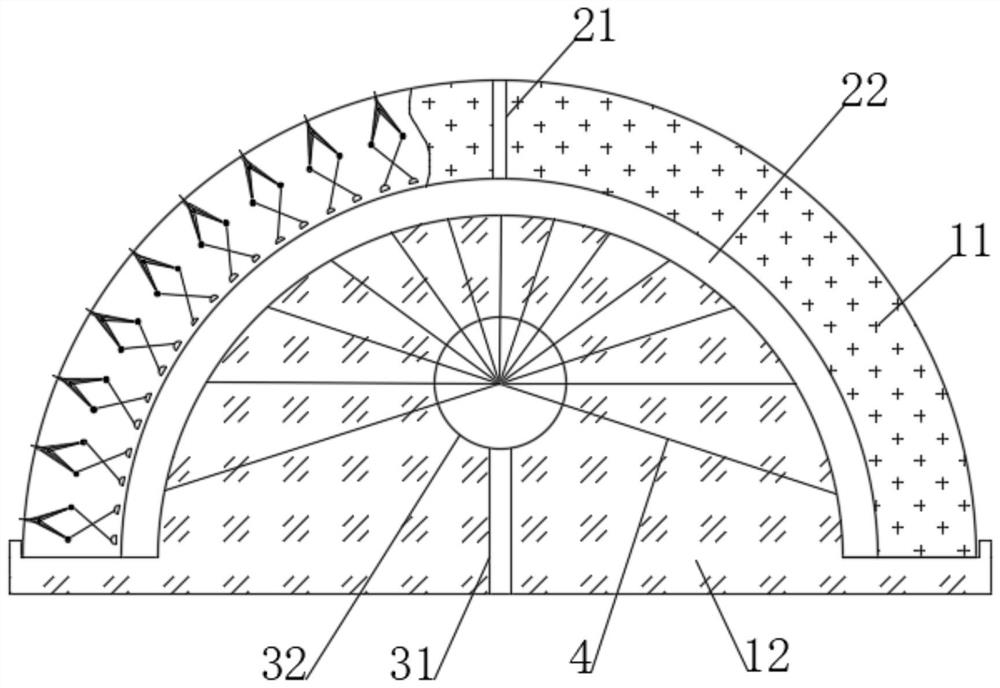

[0041] see figure 1 , a new type of high-efficiency heat dissipation injection mold, including an upper mold 11 and a lower mold 12 that match each other, and one end of the upper mold 11 and the lower mold 12 close to each other forms a mold cavity 22, and an injection port 21 is dug in the middle of the upper end of the upper mold 11, and the injection port 21 communicates with the mold cavity 22. The upper mold 11 is inlaid with a plurality of evenly distributed external conduction expansion mechanisms. The lower mold 12 is equipped with a heat collection external conduction mechanism. The heat collection external conduction mechanism includes condensation channels and a plurality of heat conduction rods 4. One end of the heat conducting rod 4 is flush with the upper surface of the lower mold 12 , and the other ends of the plurality of heat conducting rods 4 all extend into the inside of the condensation channel and contact each other.

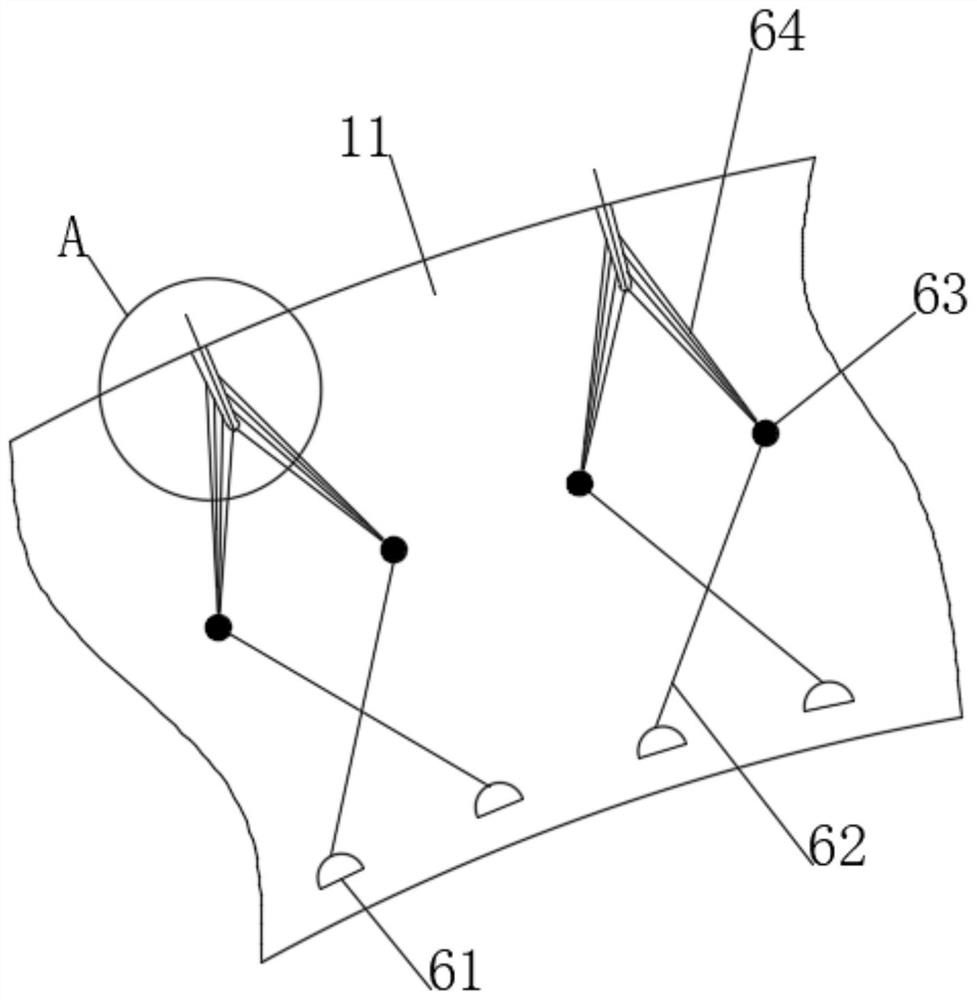

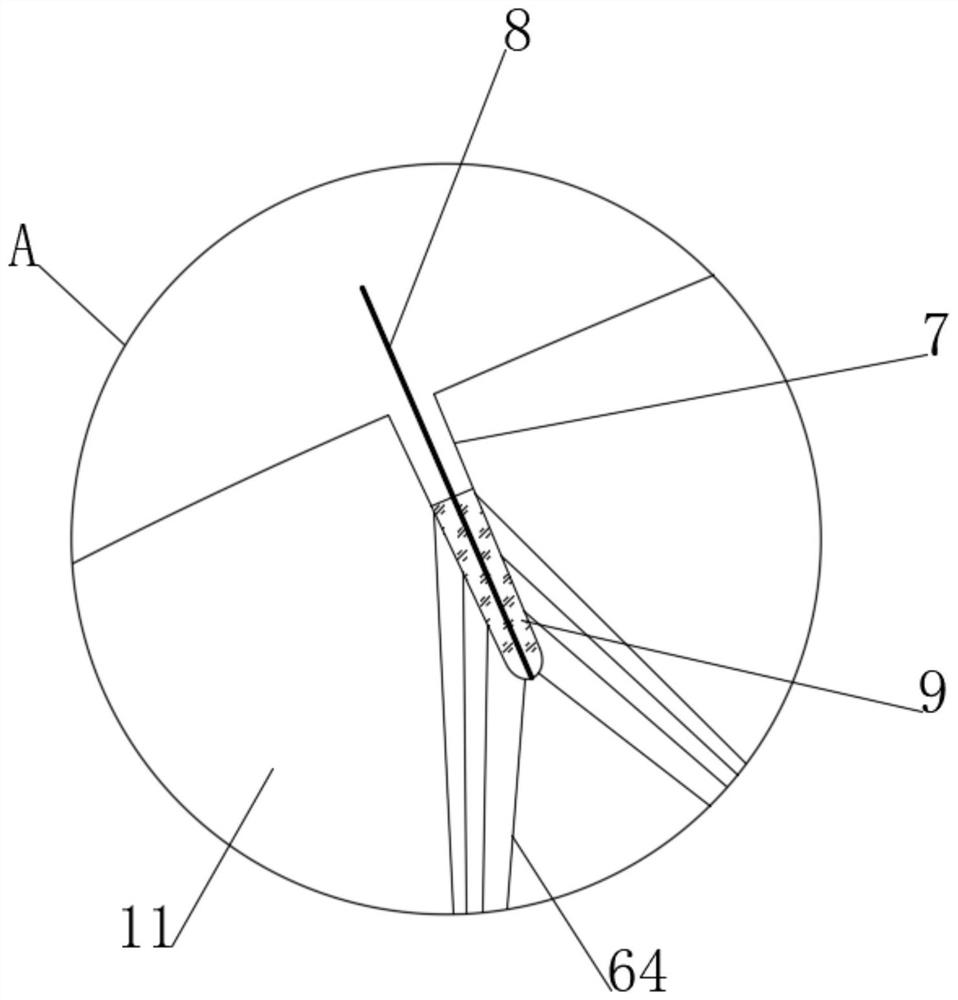

[0042] see Figure 4 The condensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com