An intelligent production system of pear borer microcapsules

A pear small borer, intelligent production technology, applied in the direction of flanged bottle caps, packaging, etc., can solve the problems of unable to maintain the hollow state, low degree of automation, low packaging efficiency, etc., to improve the connection, ensure the righting efficiency, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

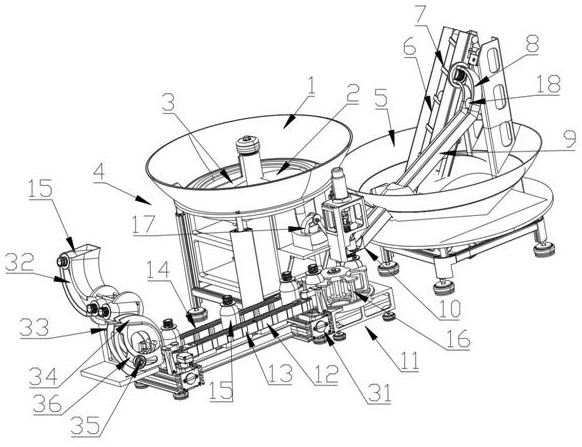

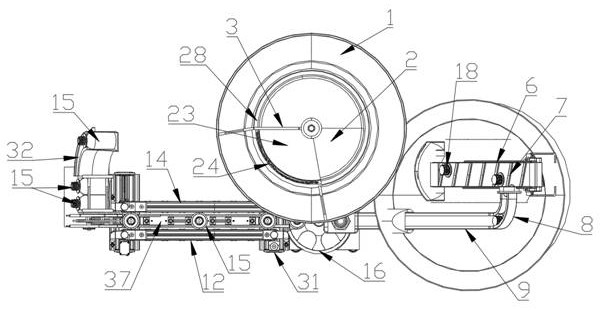

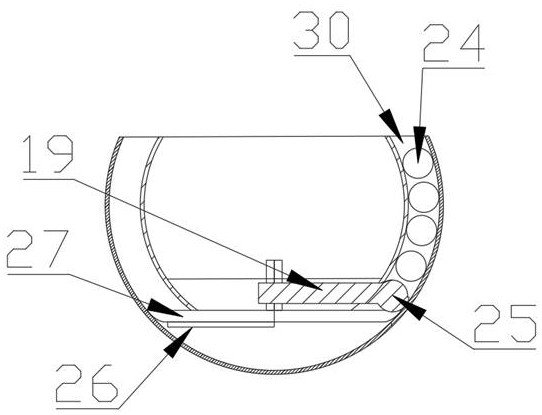

[0035] Embodiment one: a kind of intelligent production system of pear borer microcapsule 24, comprises weighing device 4, encapsulation device, toggle device 11, righting device and controller, and described weighing device 4 is configured to capsule 24 weighing, the packing device is configured to pack the storage tank 15; the toggle device 11 is configured to transport the storage tank 15; the righting device is configured to right the storage tank 15 Operation, the weighing device 4, the packaging device, the toggle device 11 and the righting device are respectively connected to the controller; the weighing device 4 includes a load-bearing plate 1, a detection unit 26, a sliding The disc 2 and the first drive mechanism, the sliding disc 2, the detection unit 26 and the weighing disc are arranged in sequence from top to bottom, and the sliding disc 2, the detection unit 26 are respectively connected to the load-bearing disc 1 coaxial arrangement, the sliding plate 2 is prov...

Embodiment 2

[0037] Embodiment 2: This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improvement on the basis thereof. Specifically, a kind of intelligent production system of pear borer microcapsules 24 is provided, including weighing Device 4, packaging device, toggle device 11, righting device, and controller, the weighing device 4 is configured to weigh the capsule 24, and the packaging device is configured to package the storage tank 15; The toggling device 11 is configured to transport the storage tank 15; the righting device is configured to perform an uprighting operation on the storage tank 15, and the weighing device 4, the packaging device, and the toggling device 11 and the centralizing device are respectively connected to the controller; specifically, the controller, as the core component of the entire system, controls the weighing device 4, the packaging device, the centralizing device, and the Coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com