Dielectric ceramic material for BT-BRT composite ultralow-loss multilayer ceramic dielectric capacitor, preparation method and application thereof

A technology of BT-BRT and dielectric ceramics, applied in the direction of fixed capacitor dielectric, stacked capacitors, capacitors, etc., can solve problems such as difficult to achieve COG characteristics, unable to meet the application requirements of ultra-low loss MLCC products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

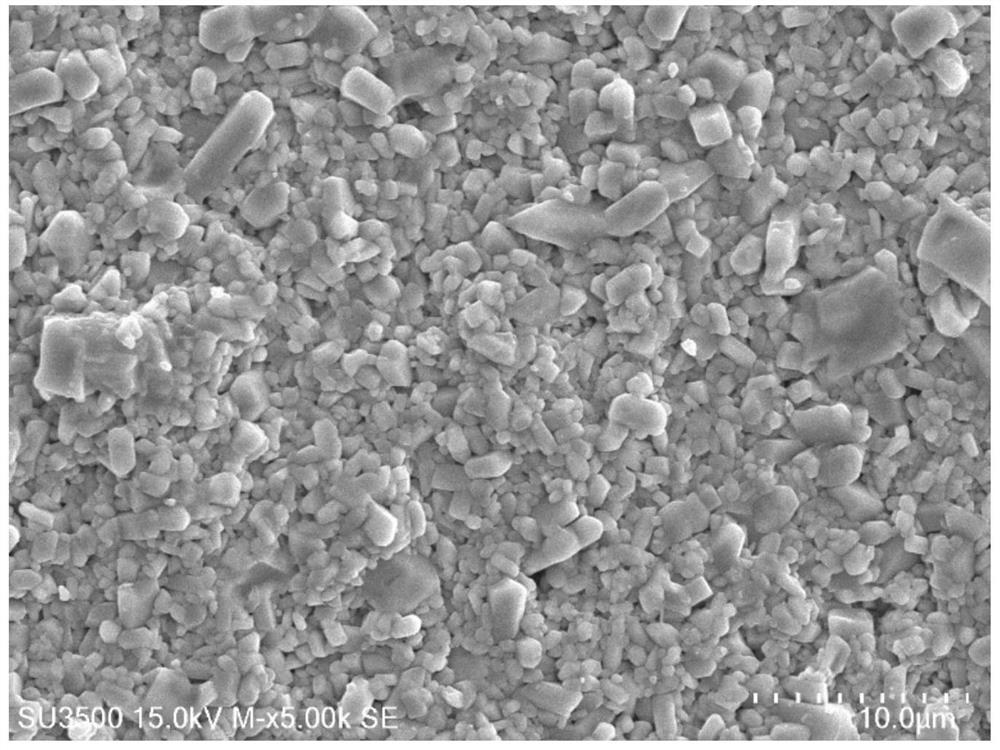

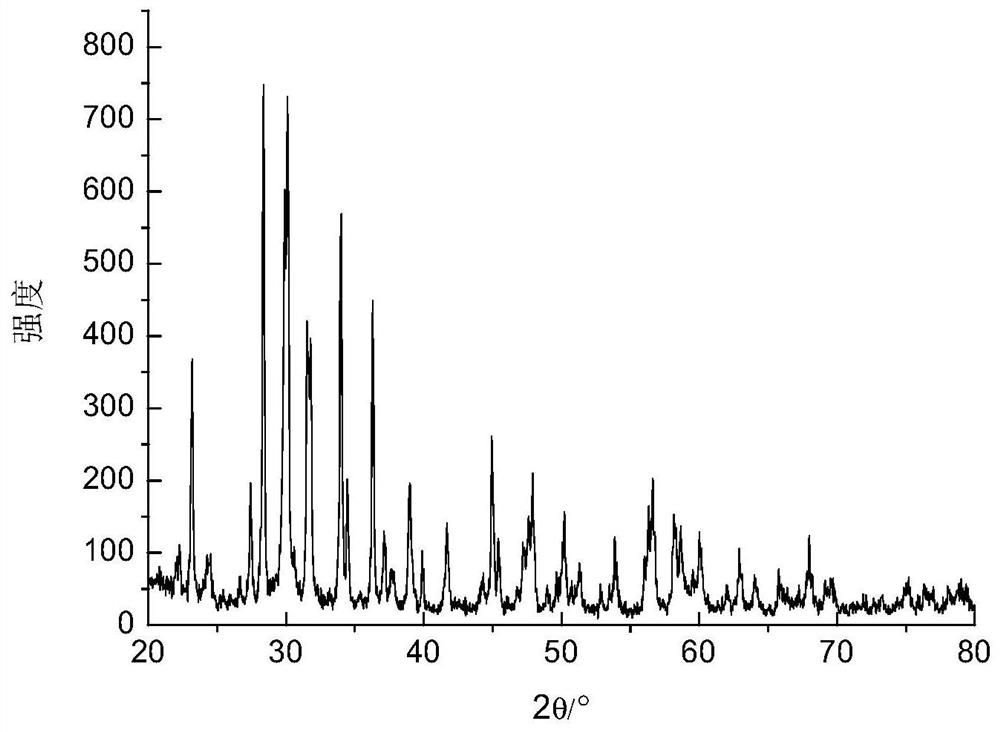

[0028] The preparation method of this dielectric ceramic material comprises: (1) Ba 2 Ti 9 o 20 Synthesis: Weigh BaCO according to the molar ratio of 1:4.5 3 and TiO 2 Mix to obtain the first mixture; then mix the first mixture, deionized water and ball milling medium in a ball mill according to the mass ratio of 1:1.5:5 and then dry; add water and sieve and send it to a heating furnace for calcination to synthesize Ba 2 Ti 9 o 20 Burn the block; in this step, the BaCO 3 and TiO 2 The powder is used to make the contact area between the two larger and more fully contacted.

[0029] (2) Ba 6-3x Re 8+2x Ti 18 o 54 Synthesis: Take x=0.4-0.6, and take BaCO according to the molar ratio of 6-3x:8+2x:18 3 、Re 2 o 3 and TiO 2 , and mixed in a ball mill to obtain a second mixture; the second mixture is sent to a heating furnace for calcination to synthesize Ba 6-3x Re 8+2x Ti 18 o 54 Burn the block; in this step, the BaCO 3 、Re 2 o 3 and TiO 2 The powder is used ...

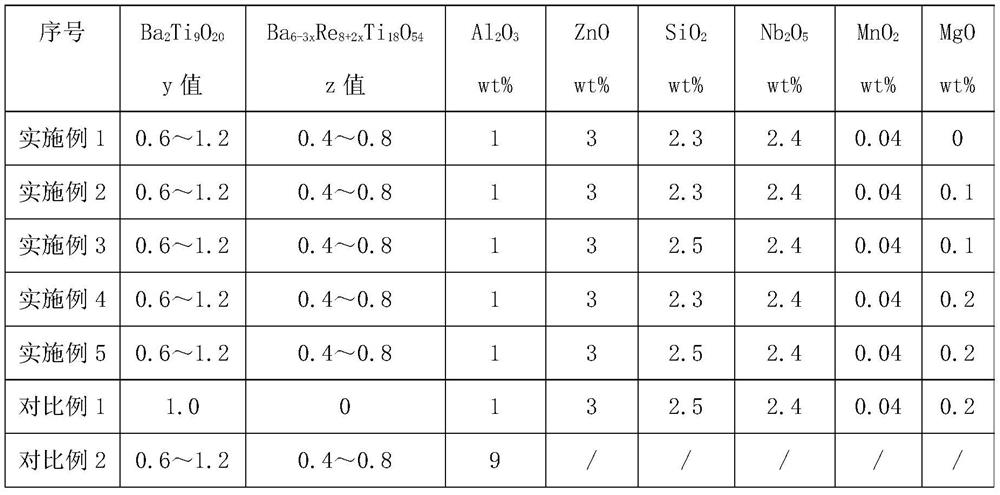

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of dielectric ceramic material for BT-BRT composite ultra-low loss multilayer ceramic capacitor, comprising: (1) Ba 2 Ti 9 o 20 Synthesis: Weigh BaCO according to the molar ratio of 1:4.5 3 Powder and TiO 2 The powder is mixed to obtain the first mixture; then the first mixture, deionized water and ball milling medium are mixed in a ball mill according to the mass ratio of 1:1.5:5 and then dried; then deionized water is added to sieve and sent to the heating furnace Calcined inside to synthesize Ba 2 Ti 9 o 20 Burnt block material; (2) Ba 6-3x Re 8+2x Ti 18 o 54 Synthesis: Take x=0.4-0.6, and take BaCO according to the molar ratio of 6-3x:8+2x:18 3 Powder, Re 2 o 3 Powder and TiO 2 powder, and mixed in a ball mill to obtain a second mixture; the second mixture is sent to a heating furnace for calcination to synthesize Ba 6-3x Re 8+2x Ti 18 o 54 (3) Preparation of dielectric ceramic material: t...

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of dielectric ceramic material for BT-BRT composite ultra-low loss multilayer ceramic capacitor, comprising: (1) Ba 2 Ti 9 o 20 Synthesis: Weigh BaCO according to the molar ratio of 1:4.5 3 Powder and TiO 2 The powder is mixed to obtain the first mixture; then the first mixture, deionized water and ball milling medium are mixed in a ball mill according to the mass ratio of 1:1.5:5 and then dried; then deionized water is added to sieve and sent to the heating furnace Calcined inside to synthesize Ba 2 Ti 9 o 20 Burnt block material; (2) Ba 6-3x Re 8+2x Ti 18 o 54 Synthesis: Take x=0.4-0.6, and take BaCO according to the molar ratio of 6-3x:8+2x:18 3 Powder, Re 2 o 3 Powder and TiO 2 powder, and mixed in a ball mill to obtain a second mixture; the second mixture is sent to a heating furnace for calcination to synthesize Ba 6-3x Re 8+2x Ti 18 o 54 (3) Preparation of dielectric ceramic material: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com