Environment-friendly primer and top-coat integrated coating special for coal machine and preparation process for coating

A briquette machine and bottom surface technology, applied in anti-corrosion coatings, rubber derivative coatings, coatings, etc., can solve problems such as environmental pollution and health hazards, and achieve the effects of simple preparation process, low construction cost, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

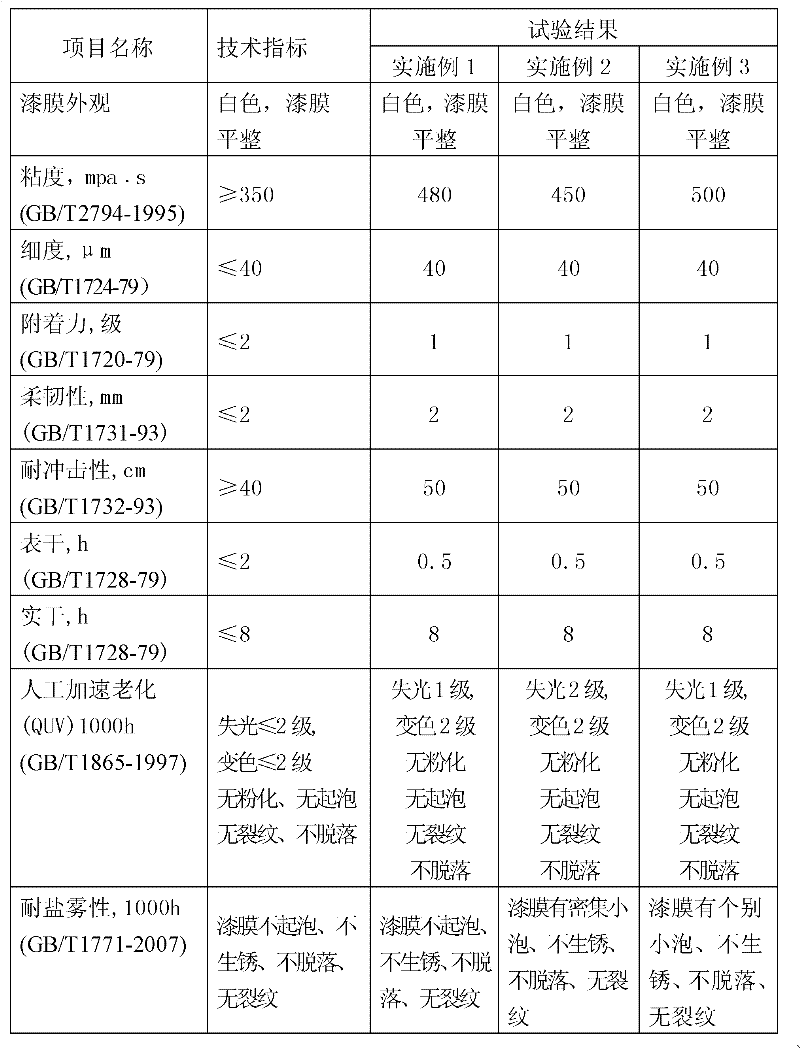

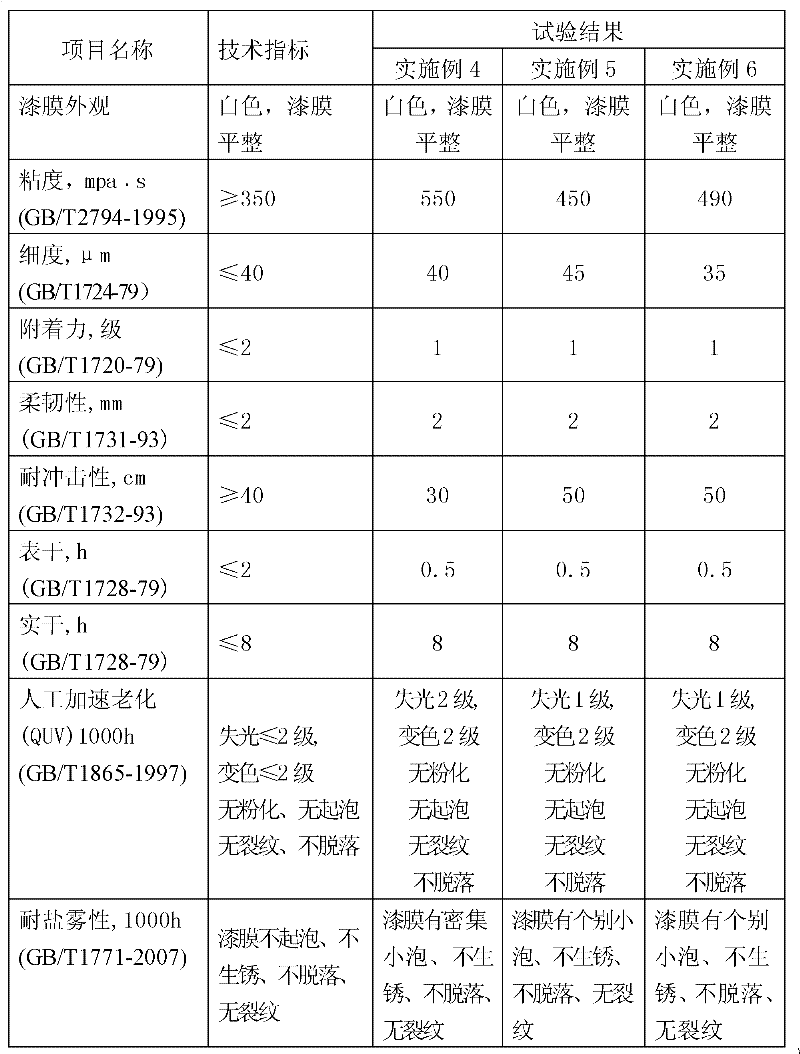

Examples

Embodiment 1

[0021] An environmental protection coal machine special bottom surface all-in-one coating, with the following formula ratio: chlorinated rubber 18wt%, phenolic resin 6wt%, dispersant 1wt%, composite iron titanium powder 8wt%, rutile titanium dioxide 20wt%, talc powder 12wt% %, anti-settling agent 2wt%, plasticizer 5wt%, solvent 28wt%, the specific preparation process is as follows:

[0022] (1) Put the phenolic resin and xylene into the reactor at a mass ratio of 1:1, stir and disperse to obtain a phenolic resin solution;

[0023] (2) Put the chlorinated rubber and xylene into the reactor at a mass ratio of 4:6, stir and disperse to obtain a chlorinated rubber solution;

[0024] (3) Evenly mix the phenolic resin solution and the chlorinated rubber solution, add a dispersant and stir to obtain a mixed solution;

[0025] (4) Put composite iron-titanium powder, rutile titanium dioxide, talc, anti-settling agent and 2 / 3 volume of solvent into the mixed solution in sequence, stir evenly, g...

Embodiment 2

[0027] An environmental protection coal machine special bottom surface all-in-one paint, with the following formula ratio: chlorinated rubber 18wt%, phenolic resin 6wt%, dispersant 1wt%, composite iron titanium powder 6wt%, rutile titanium dioxide 20wt%, talc 14wt% %, anti-settling agent 2wt%, plasticizer 5wt%, solvent 28wt%, the preparation process is the same as in Example 1.

Embodiment 3

[0029] An environmental protection coal machine special bottom surface all-in-one coating, with the following formula ratio: chlorinated rubber 18wt%, phenolic resin 6wt%, dispersant 1wt%, composite iron titanium powder 9wt%, rutile titanium dioxide 20wt%, talc powder 11wt% %, anti-settling agent 1wt%, plasticizer 5wt%, solvent 28wt%, the preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com