Cover plate culvert structure of high-earthing spoil disposal site and construction method thereof

A construction method and a technology for a waste dump, which is applied to the cover slab culvert structure and its construction field of a high-covered soil spoil site, and can solve problems such as easy leakage, inconvenient construction, and poor operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

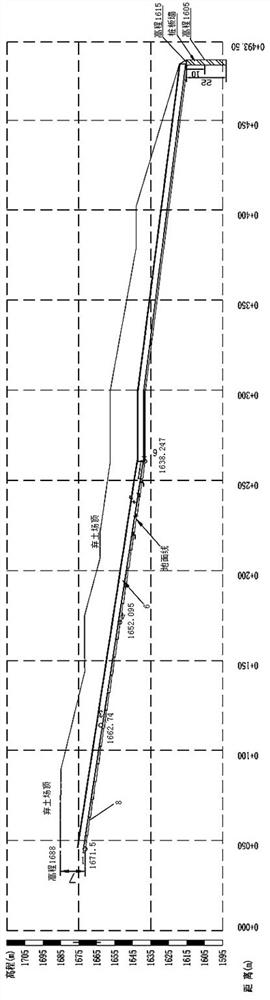

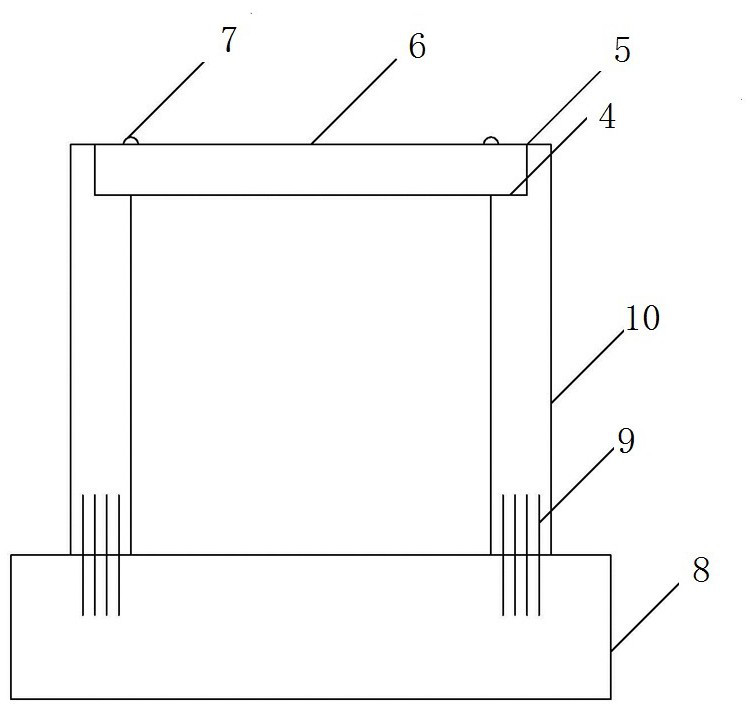

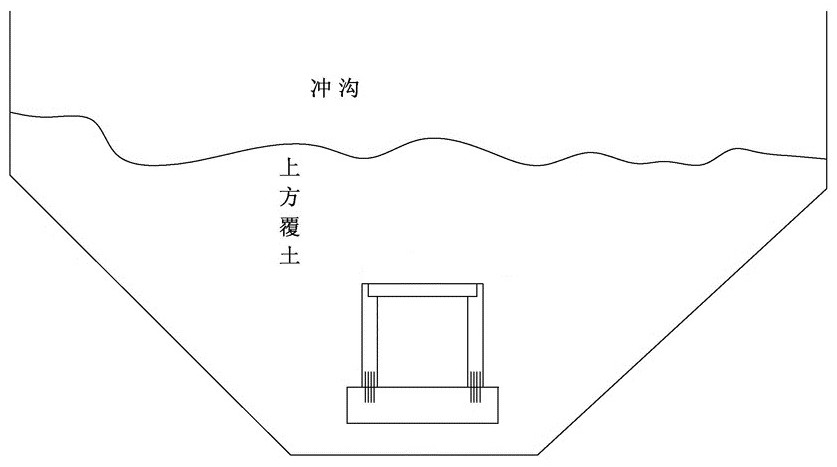

[0040] refer to Figure 1-Figure 5 As shown, the specific construction method includes the following steps:

[0041] Step 1, basic 8 processing:

[0042] After excavation, if the base allowable stress is less than 450kpa, base replacement or other measures should be taken.

[0043] If the bottom of foundation 8 is virtual slag, it must be compacted. Use steps, with a step every 10m. The foundation 8 is made of C20 rubble concrete, and the bottom is made of C20 plain concrete. Foundation 8 is 500cm wide and 120cm thick. Its vertical slope reaches 15.3%, and a slag retaining dam is constructed at the upstream end of the cover culvert 6, using C20 rubble concrete. The slag retaining dam is 44 meters long and 5 meters high, and adopts a trapezoidal structure. Mainly due to the large flow of water at the uppermost end of the cover culvert 6, in order to avoid the danger caused by a large amount of incoming water directly pouring into the spoil yard, a large-volume slag retaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com