A heat pump drying system and method

A technology of heat pump drying and drying system, which is applied in drying cargo handling, drying solid materials, drying gas layout, etc., can solve the problems of unstable moisture content of dried products, small heat exchange area, low drying efficiency, etc. The effect of uniform and efficient, improving COP coefficient and stable product moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

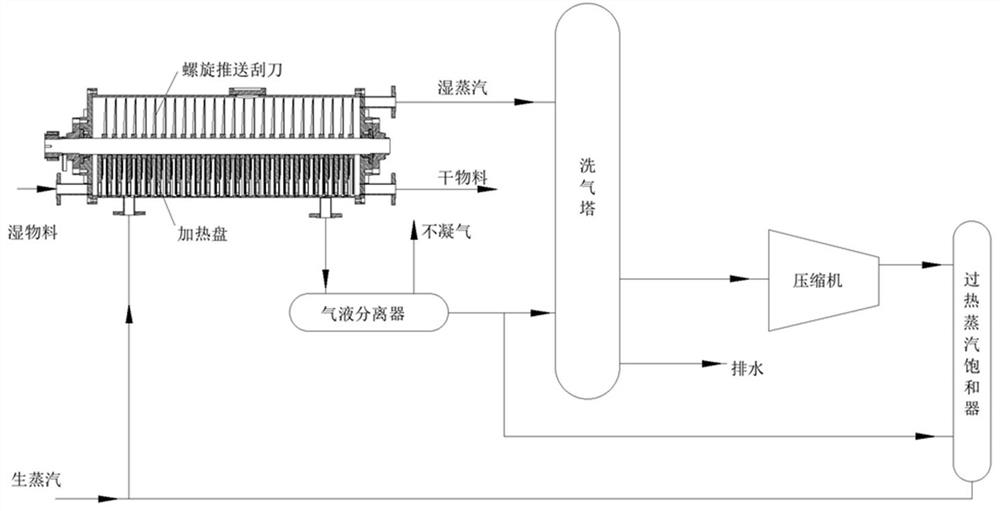

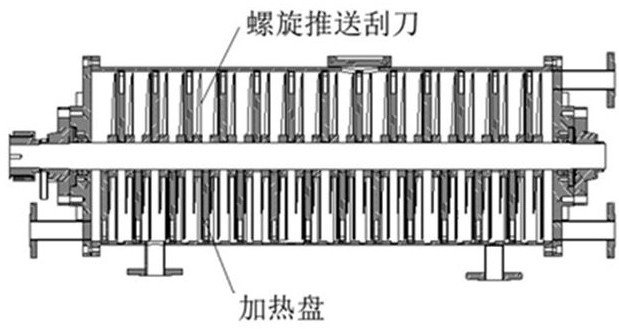

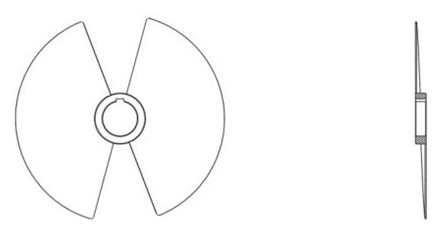

[0022] attached figure 1 It is a schematic diagram of a heat pump drying system disclosed in the present invention, which mainly includes a dryer and a heat pump system. The dryer used is a spiral push disc dryer, and the spiral push disc dryer includes a drying chamber cylinder, The central transmission shaft, the heating plate and the spiral push scraper, the heating plate is fixed on the drying chamber cylinder, has a hollow cavity, with reinforcing ribs inside, and forms a heating medium circulation flow channel at the same time, and the spiral push scraper is fixed on the central drive On the axis, the heating plate and the spiral pushing scraper are arranged alternately, the rotating surface of the spiral pushing scraper is parallel to the surface of the heating plate, and the rotating surface of the spiral pushing scraper sweeps the surface of the heating plate. The spiral pushing scraper adopts an opposing double helix structure, the helix angle is 5 degrees, and the c...

Embodiment 2

[0025] A heat pump drying method, using the spiral push disc dryer disclosed in the present invention to dry wet materials, the wet material enters the drying system continuously through the wet material inlet provided on the spiral push disc dryer, and the screw push scraper is used to dry the wet materials. Under the action of pushing, the wet material continuously moves to the dry material outlet. During the moving process, it is heated and dried by the heating plate. After the moisture content reaches the drying requirement, it is discharged from the dry material outlet to the drying system. Under the tumbling action of the spiral push scraper, the contact surface between the wet material and the heating plate is continuously updated and heated evenly, and the wet steam is discharged at the same time. In the initial stage of drying, raw steam is supplied to the cavity of the heating plate by the steam pipe, and the condensed water and non-condensable The steam enters the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com