Mass point vibration velocity sensor with wide response frequency band

A particle vibration velocity and sensor technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of high noise, limit the application scenarios and application scope of particle vibration velocity sensors, and affect the impact of particle vibration velocity sensors on broadband sound. Signal detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

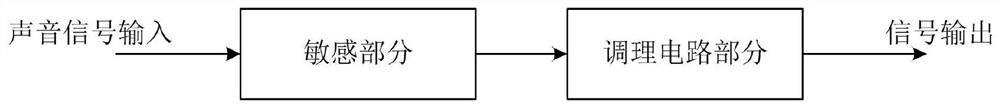

[0029] Such as figure 1 As shown, the sensor includes a sensing unit and a signal conditioning unit. The sensitive unit is composed of a plurality of sensitive subunits, and each sensitive subunit is used to collect the sound signal of the corresponding frequency band; it includes a signal conditioning unit, and the signal conditioning unit is used to amplify the electrical signal output by the sensitive unit, and to The electrical signals output by each sensitive subunit are synthesized.

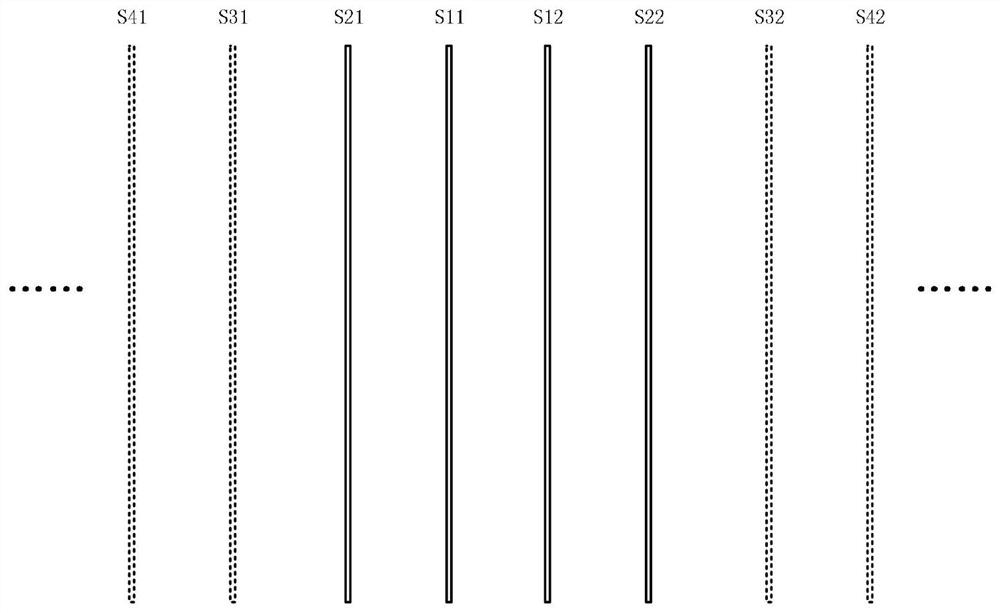

[0030] Such as figure 2 As shown, each sensitive subunit is composed of two sensitive wires arranged in parallel, and the sensitive unit includes one central sensitive subunit and one or more outer sensitive subunits. In this embodiment, the central sensitive subunit The unit is composed of sensitive wires S11 and S12, and also includes an external sensitive subunit composed of sensitive wires S21 and S22, an external sensitive subunit composed of sensitive wires S31 and S32, an external...

Embodiment 2

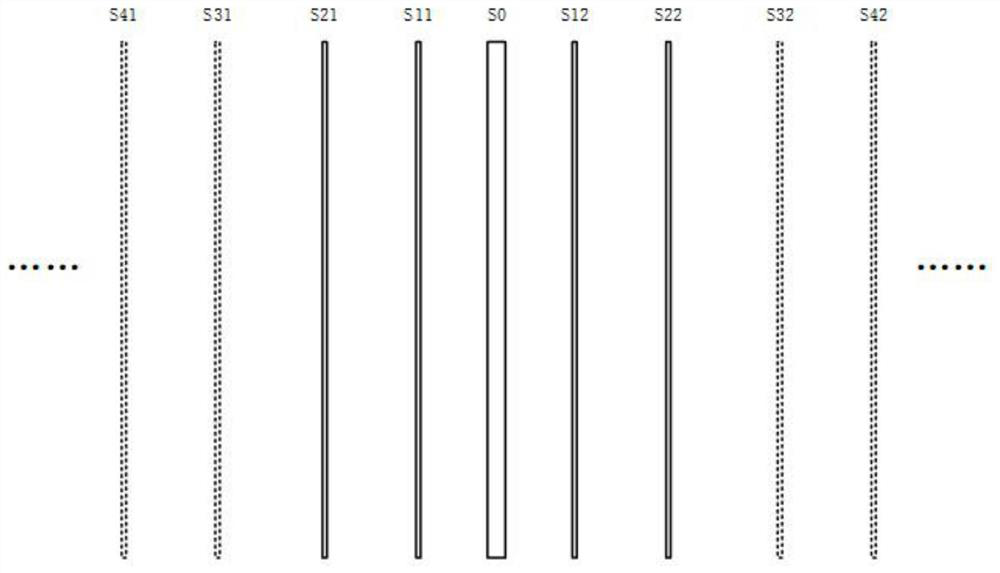

[0035] Such as image 3 As shown, in the middle position between the sensitive wires S11 and S12 of the central sensitive sub-unit, there is a heating wire S0, through which the response effect of the sensitive unit can be further improved.

[0036] The remaining structures and working principles of the second embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com