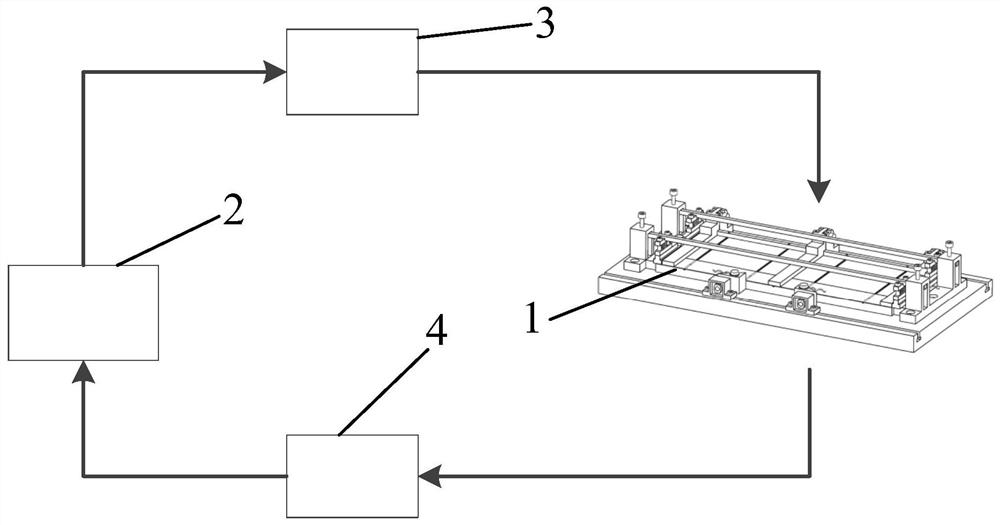

Device and system suitable for measuring conductivity of strip-shaped electrical material at different temperatures

A technology for measuring devices and electrical materials, applied to measuring devices, electrical devices, and parts of thermometers, etc., can solve the problems of improving the actual work efficiency of laboratories and projects, the difficulty of applying peak temperature to meet actual needs, and the lack of measuring equipment. , to achieve the effect of solving the difficulty of production, good scope of application, and weakening of measurement constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

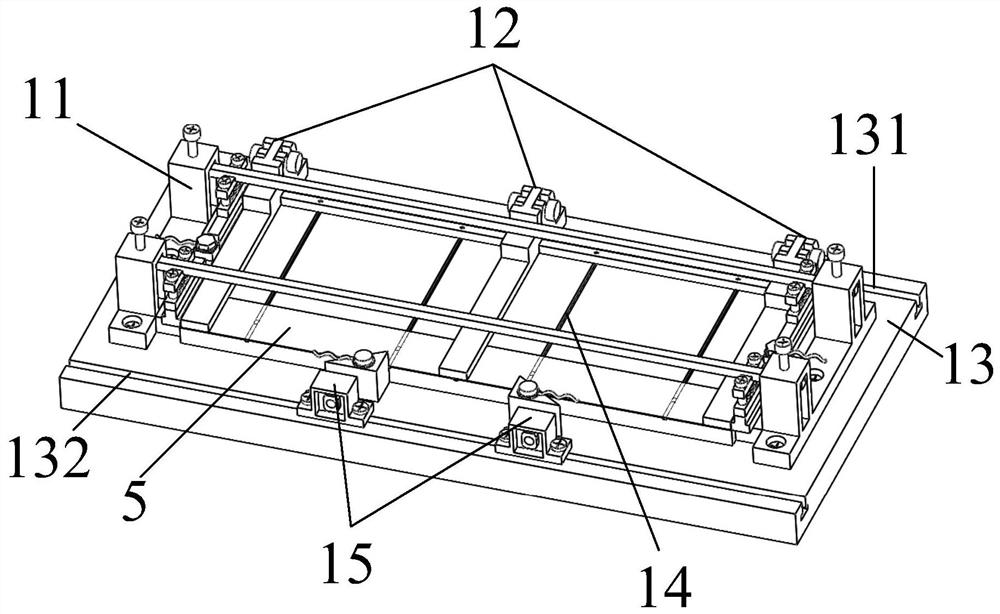

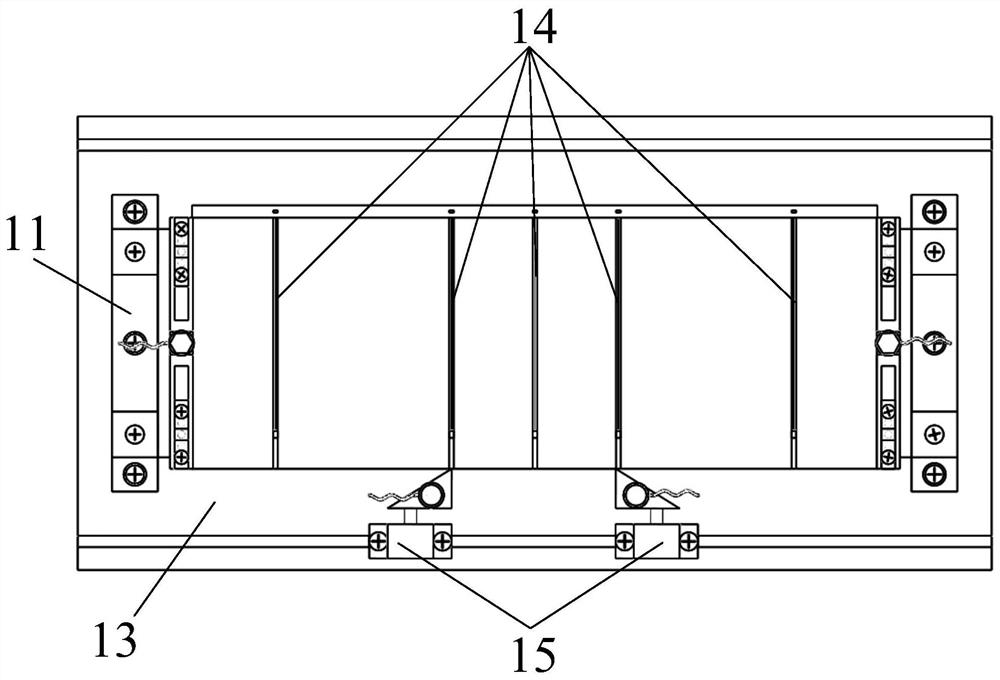

[0032] Specific embodiments of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of this application.

[0033] The present invention provides a conductivity measuring device (referred to as the measuring device) suitable for strip-shaped electrical materials at different temperatures, which is characterized in that the measuring device 1 includes a current applying mechanism 11, a sample pressing mechanism 12, a measuring platform 13, a thermoelectric Couple 14 and measuring voltage mechanism 15; The current applying mechanism 11 includes a pressure rod adjustment seat 111, a height adjustment screw 112, a pressure rod 113, an energization mechanism 114, and an adjustment seat fixing screw 115;

[0034] Two pressure rod adjustment seats 111 are fixed on both sides of the measurement platform 13 by adjusting seat fixing screws 115; at least two pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com