bga heat dissipation structure and bga heat dissipation packaging method

A technology of heat dissipation structure and packaging method, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc. It can solve the problems of chip structure influence, product heat dissipation performance, chip and heat dissipation cover cavity, etc., to ensure heat dissipation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

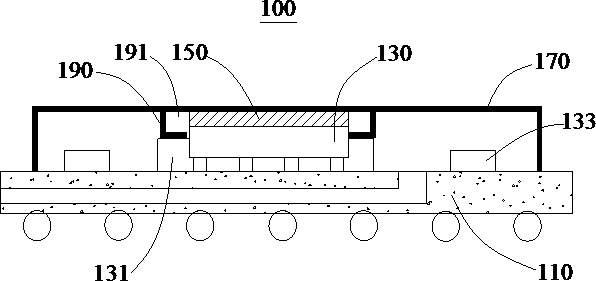

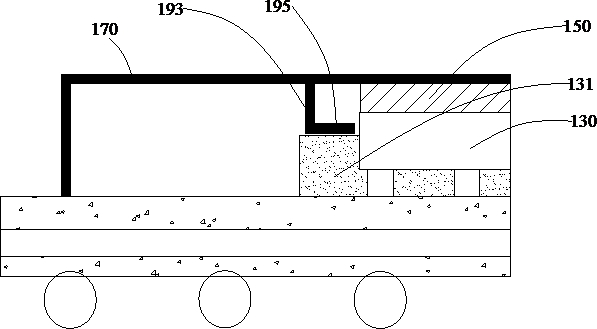

[0049] Please refer to figure 1 , this embodiment provides a BGA heat dissipation structure 100, which can prevent the overflowing mixture from affecting the structural safety of the chip 130 during reflow soldering, and can prevent too much overflowing of the mixture from affecting the heat dissipation performance, and at the same time can make the glue be heated more uniformly. Avoid product damage.

[0050]The BGA heat dissipation structure 100 provided in this embodiment includes a substrate 110, a chip 130, a heat sink 150 and a heat dissipation cover 170. The chip 130 is mounted on the substrate 110, the heat sink 150 is mounted on the chip 130, and the heat dissipation cover 170 is covered on the On the substrate 110 around the chip 130, and mounted on the heat sink 150, wherein, the heat dissipation cover 170 is provided with an overflow ring structure 190, the overflow ring structure 190 is arranged around the chip 130, and forms an overflow groove 191, and the overfl...

no. 2 example

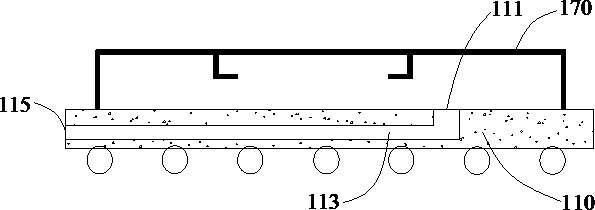

[0070] This embodiment provides a BGA heat dissipation structure 100. Its basic structure, principle and technical effect are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the Correspondingly, the difference between this embodiment and the first embodiment lies in the structure of the substrate 110 .

[0071] see Figure 4 , in this embodiment, the bottom of the heat dissipation cover 170 is bonded to the substrate 110 by a sealant to form an internal cavity. The upper surface of the substrate 110 is also provided with an internal exhaust hole 111 communicating with the internal cavity. The substrate 110 is also provided with an exhaust groove 113 communicating with the internal exhaust hole 111. The exhaust groove 113 is arranged below the chip 130 and extends to the external space. The bottom surface of the substrate 110 is also provided with a bottom exhaust hole 117. The bottom exhaust hole 117 c...

no. 3 example

[0076] This embodiment provides a BGA heat dissipation structure 100. Its basic structure, principle and technical effect are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the Correspondingly, the difference between this embodiment and the first embodiment lies in the structure of the substrate 110 .

[0077] see Figure 5, in this embodiment, the bottom of the heat dissipation cover 170 is bonded to the substrate 110 by a sealant to form an internal cavity. The upper surface of the substrate 110 is also provided with an internal exhaust hole 111 communicating with the internal cavity. The substrate An exhaust groove 113 communicating with the internal exhaust hole 111 is also provided in the 110, and the exhaust groove 113 is arranged under the chip 130 and extends to the external space.

[0078] In this embodiment, a side wall exhaust hole 115 is further provided on the side wall of the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com