A prefabricated sewage tank, its installation method and leakage monitoring method

A kind of sewage pool and assembled technology, which is applied in large-capacity bulk material storage, by measuring the increase and deceleration rate of fluid, and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of polluted groundwater, water and soil loss around the pool, Leakage and other issues are eliminated, achieving the effects of less on-site labor input, controllable production accuracy, and environmental protection in the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

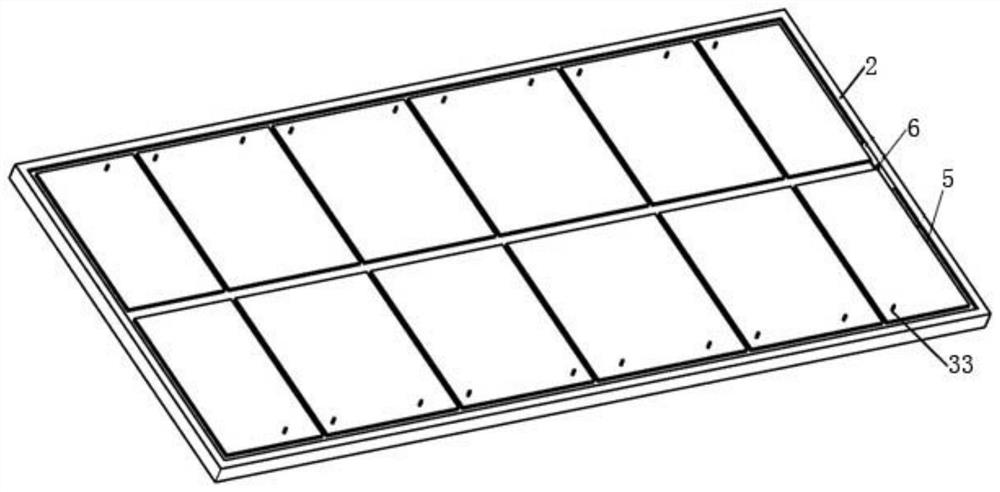

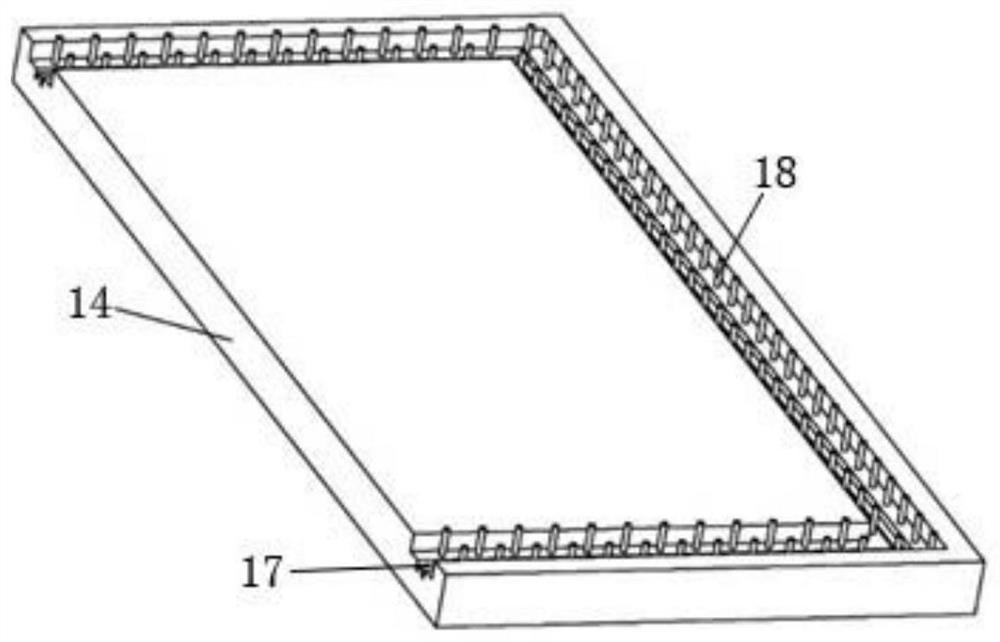

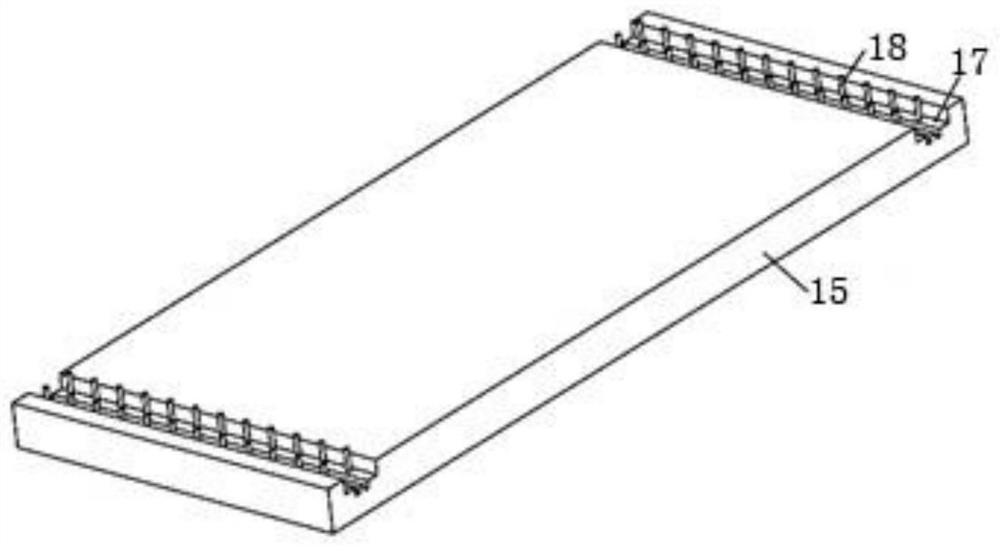

[0039] Such as figure 1 and Figure 9 As shown, a prefabricated sewage tank includes a sewage tank body and a leakage monitoring system. The sewage tank body includes a pool wall 1, a bottom plate 2, a partition 3 and a cushion 4, and the cushion is provided with criss-cross water collection ditches 5. A grid structure is formed. There is also a water collecting ditch around the cushion, and a cushion outlet 6 is provided at the center of one side. It is formed by a plurality of prefabricated pool wall components 8 arranged around the bottom plate, and the prefabricated pool wall components are assembled radially in the sewage tank body to form a partition.

[0040] Such as Figure 8 As shown, the leakage monitoring system includes a water storage tank 9, a liquid level sensor 10, a regulating tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com