High-capacity composite negative electrode material, preparation method and lithium ion battery

A negative electrode material and high-capacity technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low cobalt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

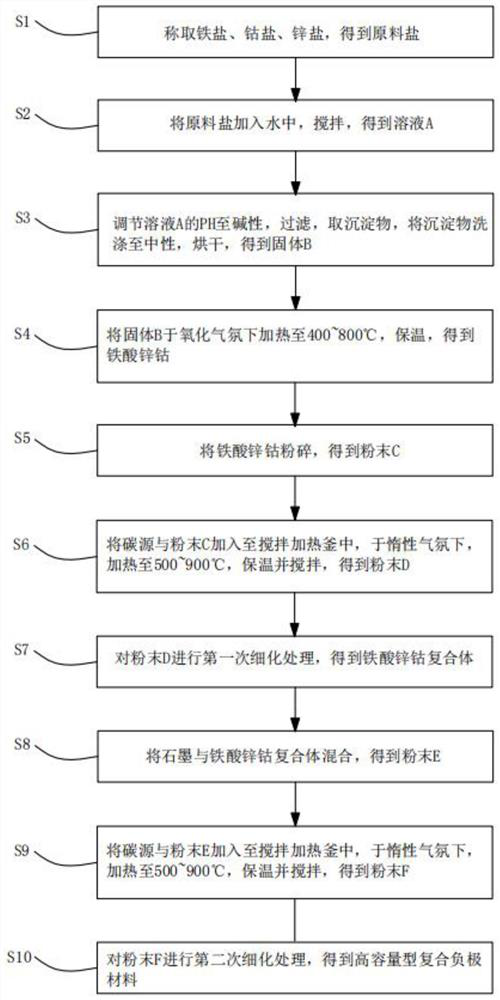

[0045] Another object of the present invention is to provide a method for preparing the above-mentioned high-capacity composite negative electrode material, see image 3 As shown, the method includes:

[0046] S1: weighing iron salt, cobalt salt, and zinc salt to obtain raw material salt;

[0047] S2: adding raw material salt into water and stirring to obtain solution A;

[0048] S3: adjusting the pH of the solution A to be alkaline, filtering, taking the precipitate, washing the precipitate until neutral, and drying to obtain a solid B;

[0049] S4: heating the solid B to 400-800° C. in an oxidizing atmosphere, and keeping it warm to obtain zinc-cobalt ferrite;

[0050] S5: pulverizing zinc-cobalt ferrite to obtain powder C;

[0051] S6: Add carbon source and powder C into a stirring heating kettle, heat to 500-900°C under an inert atmosphere, keep warm and stir to obtain powder D;

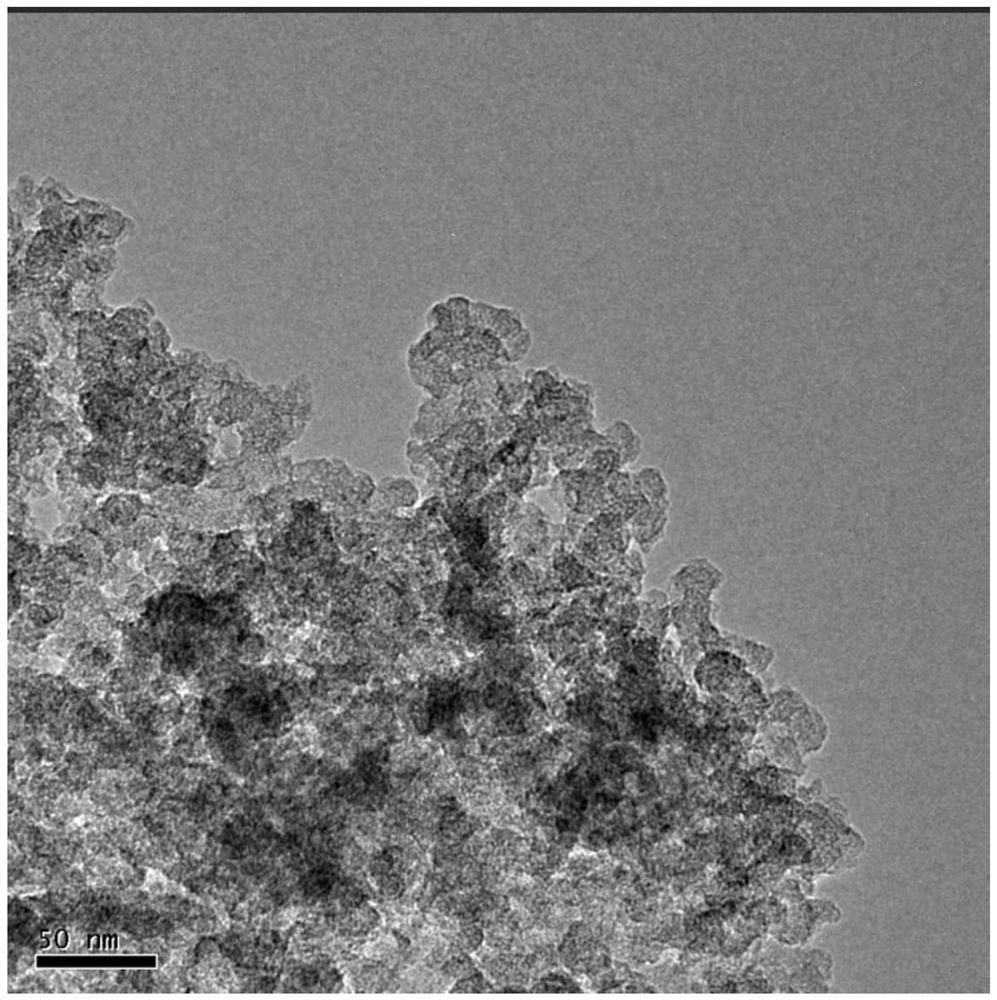

[0052] S7: performing the first refinement treatment on the powder D to obtain a zinc-cob...

Embodiment 1

[0072] This embodiment provides a method for preparing a high-capacity composite negative electrode material, the preparation method comprising:

[0073] S1: weighing iron chloride, cobalt chloride, and zinc chloride according to the molar ratio of iron element, cobalt element, and zinc element being 2:0.5:0.5 to obtain raw material salt;

[0074] S2: add 100g raw material salt into 1000g water, stir to obtain solution A;

[0075] S3: adjusting the pH of the solution A to be alkaline, filtering, taking the precipitate, washing the precipitate until neutral, and drying to obtain a solid B;

[0076] S4: heating the solid B to 400° C. under an oxygen atmosphere and keeping it warm for 0.5 hours to obtain zinc-cobalt ferrite;

[0077] S5: Grinding zinc-cobalt ferrite to a particle size of 50 nm to obtain powder C;

[0078] S6: Add 20g of sucrose and 40g of powder C into a stirring heating kettle, heat to 500°C under a nitrogen atmosphere, keep warm and stir for 0.5 hours to obta...

Embodiment 2

[0087] This embodiment provides a method for preparing a high-capacity composite negative electrode material, the preparation method comprising:

[0088] S1: weighing iron chloride, cobalt chloride, and zinc chloride according to the molar ratio of iron element, cobalt element, and zinc element being 2:0.5:0.5 to obtain raw material salt;

[0089] S2: Add 100g of raw material salt into 3000g of water and stir to obtain solution A;

[0090] S3: adjusting the pH of the solution A to be alkaline, filtering, taking the precipitate, washing the precipitate until neutral, and drying to obtain a solid B;

[0091] S4: heating the solid B to 600° C. under an air atmosphere and keeping it warm for 2 hours to obtain zinc cobalt ferrite;

[0092] S5: Grinding zinc-cobalt ferrite to a particle size of 100 nm to obtain powder C;

[0093] S6: Add 120g of pitch and 40g of powder C into a stirring heating kettle, heat to 700°C under an argon atmosphere, keep warm and stir for 2 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap