Metal circular high-voltage connector with five hole sites arranged in mixed manner

A high-voltage connector and mixed assembly technology, which is applied in the direction of contact parts, base/housing, etc., can solve the problem of high cost of stamping terminals, and achieve the effects of saving space, saving costs, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

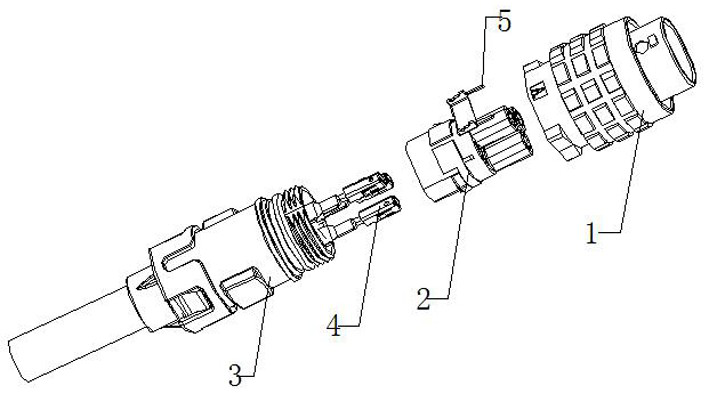

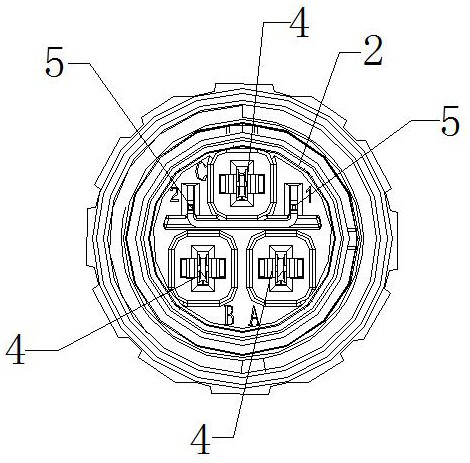

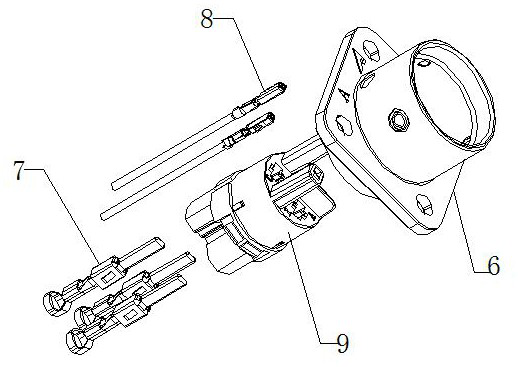

[0016] Such as Figure 1-4 As shown, a metal circular high-voltage connector with 5 holes arranged in a mixed arrangement includes a plug housing assembly 1 and a socket housing assembly 6 matching the house type, the plug housing assembly 1 and the plug assembly 3 are fixed to each other, and the plug housing assembly 1 There is a sheath I2 between the plug assembly 3, and the sheath I2 is provided with a power jack 4 and an interlocking pin 5. The mating area of the power jack is wrapped in the sheath, and the pairing of the interlocking pins The insertion area protrudes outside the sheath, and the socket shell assembly 6 is fixed with a sheath II9, on which the power pin 7 and the interlocking jack 8 are arranged, and the mating area of the interlocking jack is wrapped in the sheath, And the plug-in area of the power pin protrudes outside the sheath.

[0017] There are three power jacks 4, which are arranged in the shape of a finished product on the sheath I2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com