Device and process for producing organic fertilizer applied to symbiotically potted pterocarpus santalinus and dendrobium nobile

The technology of a lobular red sandalwood and a production device is applied in the directions of a mixer, a heating device, a mixer and the like with a rotary stirring device, which can solve the problems of reducing storage time, deterioration of fertilizer, uneven fertilizer composition, etc. The effect of reducing fertilizer deterioration and facilitating full discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

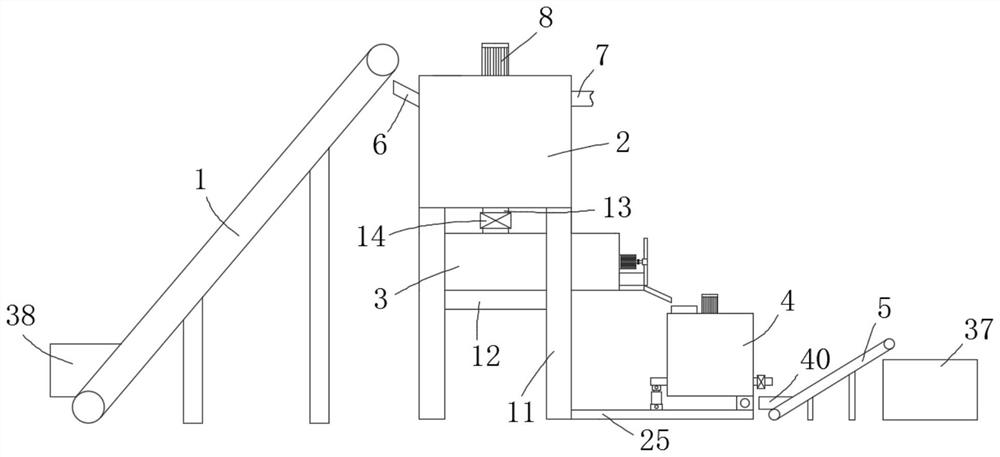

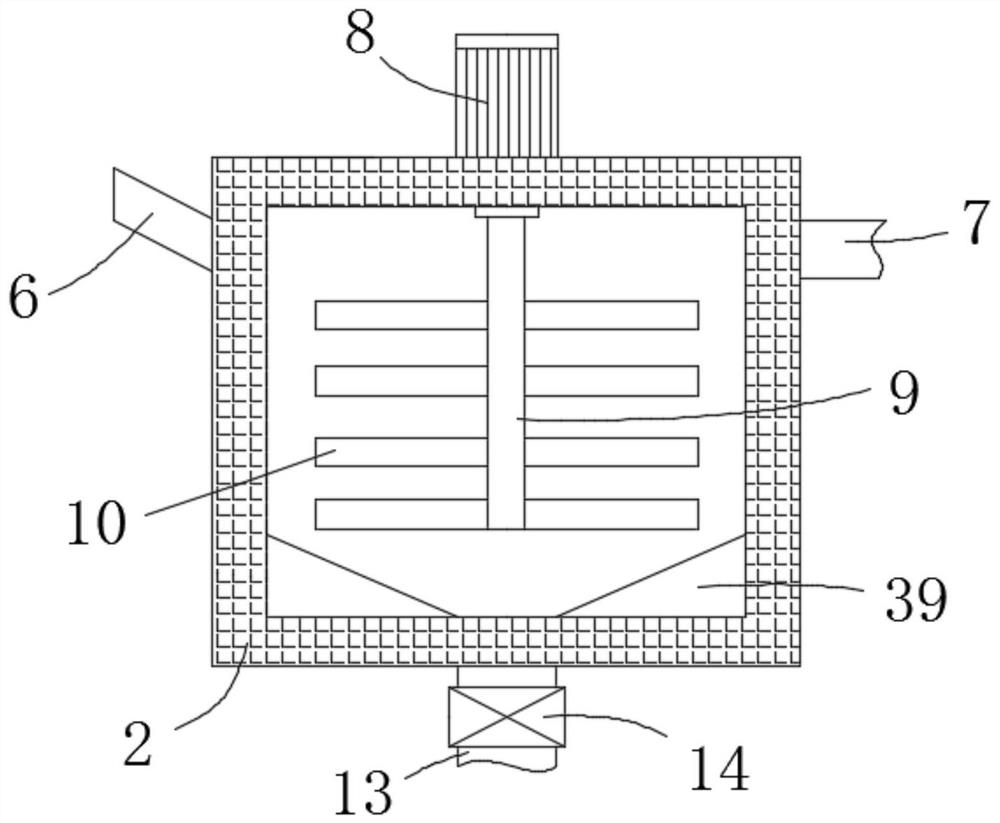

[0038] A technical solution is provided: an organic fertilizer production device for symbiosis potted plants of red sandalwood and dendrobium, comprising a first conveyor belt 1, a mixing box 2, a conveying pipe 3, a drying box 4, and a second conveying belt 5. One side of the material box 2 is connected with a first feed port 6, the top end of the first conveyor belt 1 is provided above the first feed port 6, and the other side of the mixing box 2 is connected with a liquid inlet pipe 7. A first motor 8 is installed on the top of the mixing box 2, and the output end of the first motor 8 is connected to a first rotating shaft 9 through a coupling transmission. The first rotating shaft 9 is rotatably connected with the top of the mixing box 2. The first rotating shaft 9 A first stirring rod 10 is welded on the circumference of;

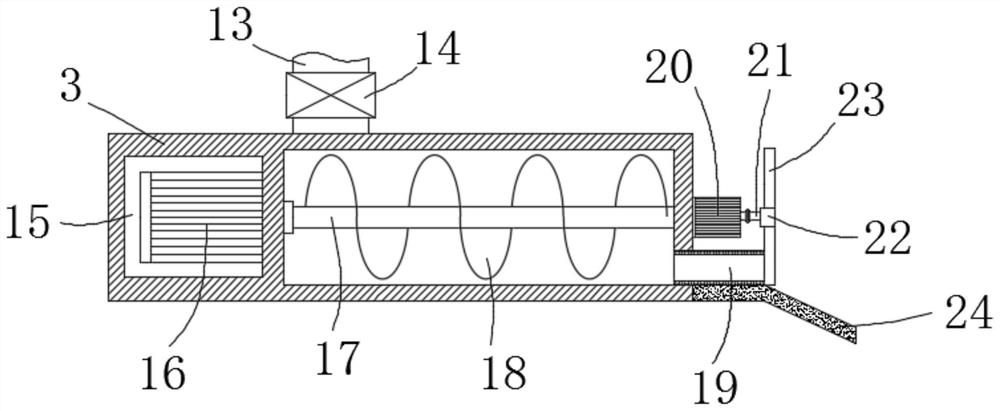

[0039] The bottom of the mixing box 2 is welded on all four sides with feet 11, the inner side of the feet 11 is welded with a supporting plate 12, the c...

Embodiment 2

[0050] The difference from Example 1 is that it also provides an organic fertilizer production process for symbiosis potting of Pterocarpus striata and Dendrobium, including the following steps:

[0051] S1. First, feed the raw materials into the mixing box 2 through the first conveyor belt 1, and add an appropriate amount of mixed liquid through the liquid inlet pipe 7;

[0052] S2. Start the first motor 8, so that the first motor 8 drives the first rotating shaft 9 to rotate, and the first rotating shaft 9 drives the first stirring rod 10 to rotate, so that the first stirring rod 10 stirs the raw materials and mixes them fully;

[0053] S3. Open the first valve 14 so that the mixed raw materials are discharged into the delivery pipe 3 through the discharge pipe 13;

[0054] S4. Start the second motor 16 so that the second motor 16 drives the second rotating shaft 17 to rotate, and the second rotating shaft 17 drives the conveying blade 18 to rotate, so that the conveying blade 18 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com