Continuous and efficient soil remediation device

A soil remediation and high-efficiency technology, applied in the field of soil remediation, can solve the problems of limited soil remediation effect, waste, volatile chemicals, etc., achieve good repair effect, reduce waste, and ensure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

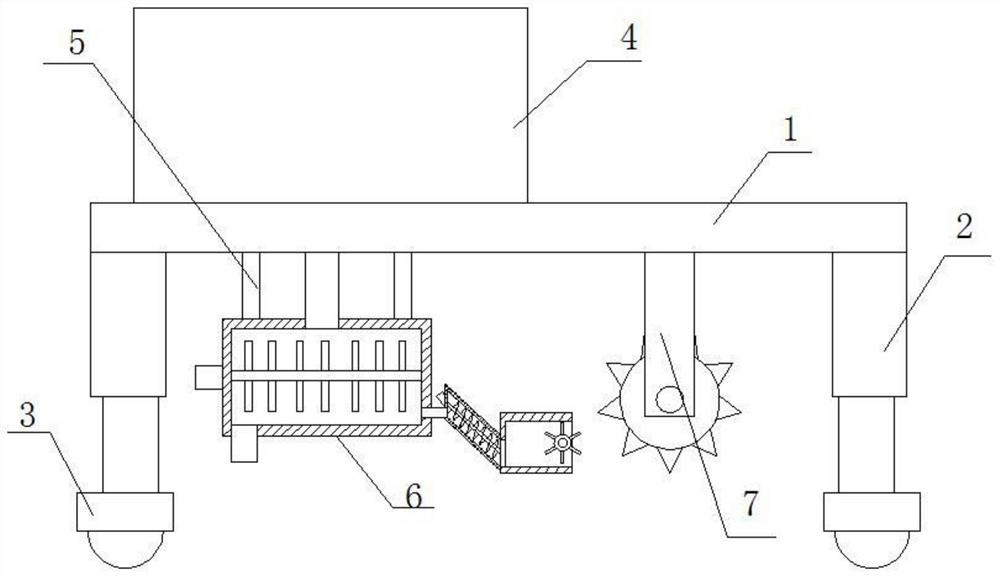

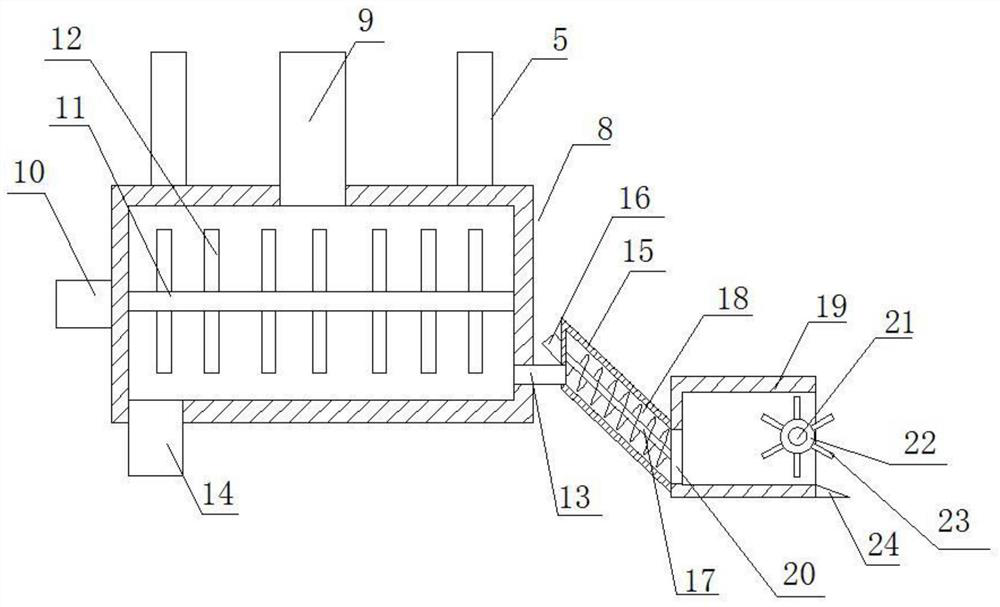

Embodiment 1

[0024] see Figure 1-5 , in an embodiment of the present invention, a continuous and efficient soil remediation device includes a frame 1, electric telescopic legs 2 are arranged at the four corners of the lower end of the frame 1, and universal wheels 3 are installed at the lower ends of the electric telescopic legs 2 The upper side of the frame 1 is provided with a repair agent box 4, the lower left part of the frame 1 is connected with a repair mechanism 6 through a connecting rod 5, and the lower right part of the frame 1 is provided with a soil-turning mechanism 7, the The repair mechanism 6 includes a repair box 8, the upper end of the repair box 8 is connected with the repair agent box 4 through the liquid inlet pipe 9, the upper end of the repair box 8 is connected with the frame 1 through the connecting rod 5, and a stirring mechanism is arranged in the repair box 8 , the right end of the repair box 8 is provided with a soil feeding pipe 13, the lower left end of the ...

Embodiment 2

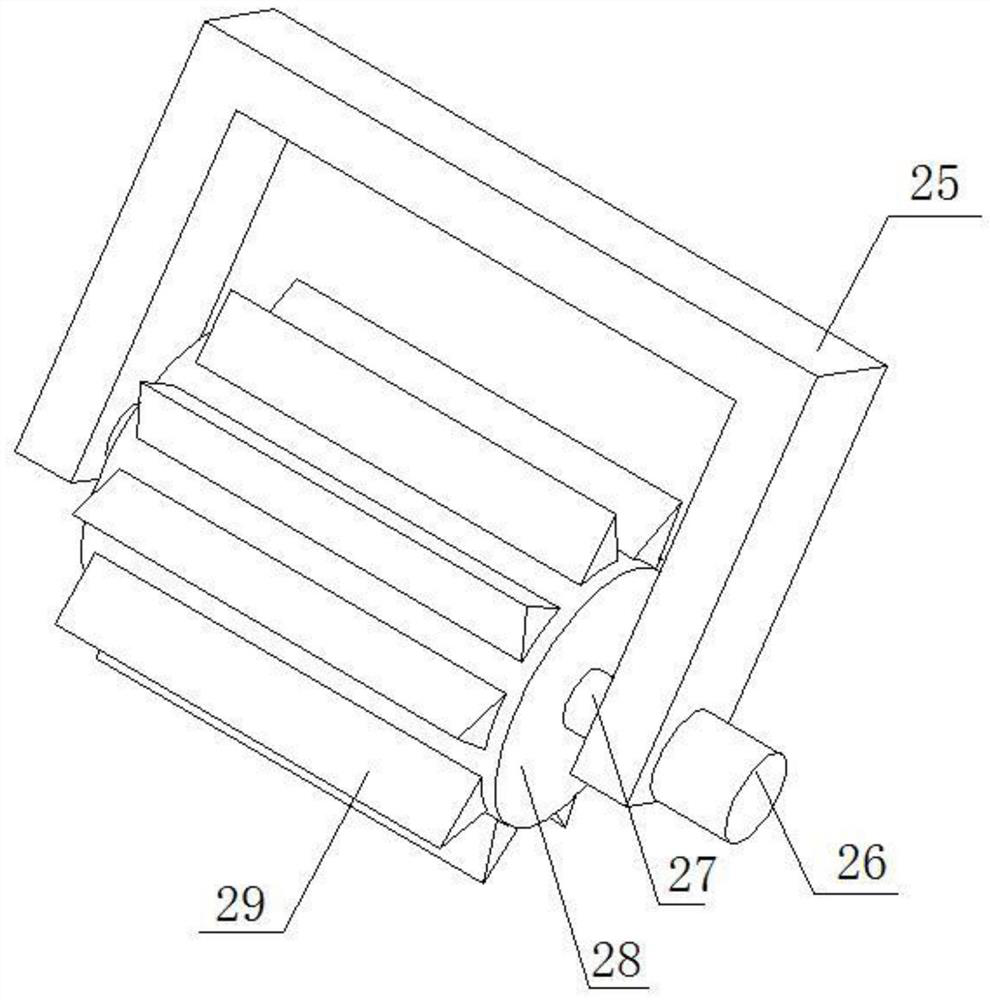

[0030]On the basis of Embodiment 1, the soil turning mechanism includes a bracket 25, a third motor 26 is installed on the outside of the lower end of the bracket 25, and the output end of the third motor 26 is provided with a rotating shaft 27 that is rotatably connected to the bracket 25 , the outer side of the rotating shaft 27 is provided with a rotating cylinder 28, and the outer side of the rotating cylinder 28 is provided with a plurality of tilling knives 29. The structural arrangement of the device drives the rotary cylinder to rotate through the third motor, so that the soil is turned by the tiller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com