Bracelet forming and manufacturing device

A technology for making devices and bracelets, which can be applied to bracelets, feeding devices, positioning devices, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

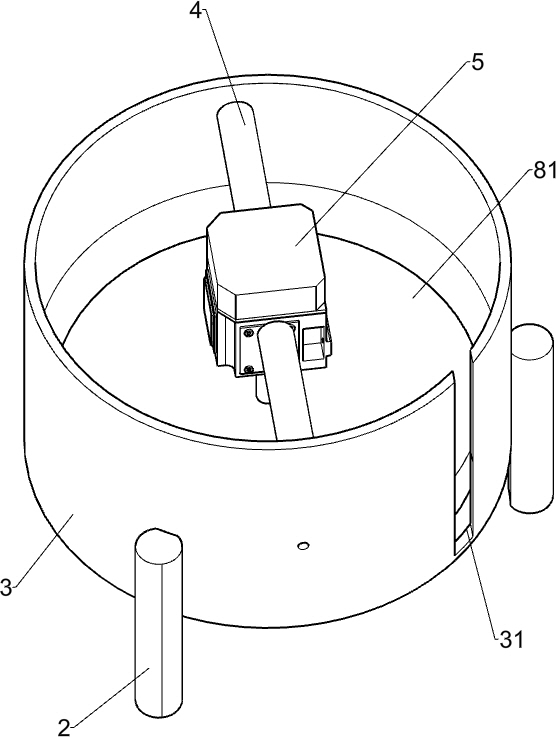

[0061] A bracelet forming device, such as figure 1 with 8 As shown, it includes support table 1, support feet 2, extrusion frame 3, fixed rod 4, motor 5, push mechanism 6, discharge mechanism 7 and forming pressure plate 81, and the left side of the top of support table 1 is evenly connected with three supports An extrusion frame 3 is connected between the foot 2 and the support foot 2, and the right rear side of the extrusion frame 3 is provided with a feed port 31, and a fixed rod 4 is connected between the upper side of the extrusion frame 3, and a motor is connected in the middle of the fixed rod 4 5. The bottom of the output shaft of the motor 5 is connected with a forming pressure plate 81, and the forming pressure plate 81 is connected with the extrusion frame 3 in a rotational manner. The right side of the top of the support table 1 is connected with the push mechanism 6, and the left side of the push mechanism 6 is connected with the motor 5 to support A discharge me...

Embodiment 2

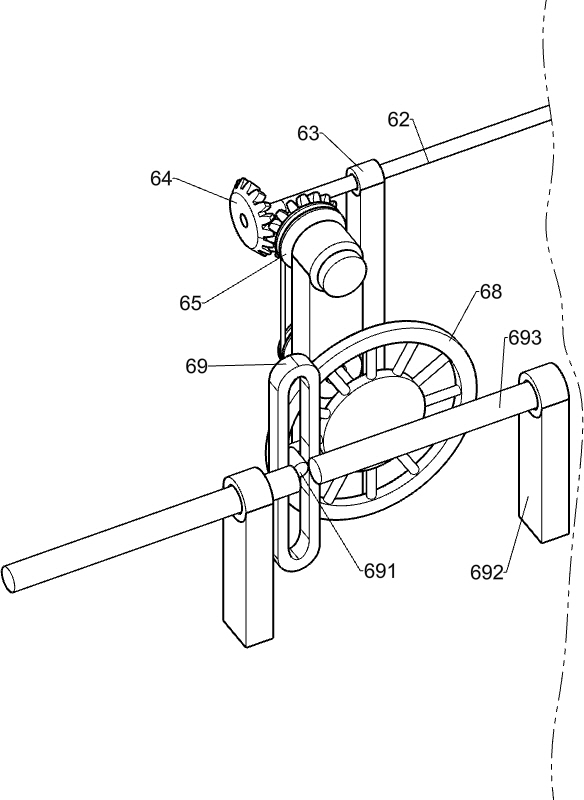

[0064] On the basis of Example 1, such as Figure 2-4 As shown, the push mechanism 6 includes a first bevel gear set 61, a first transmission rod 62, a first support shaft 63, a second bevel gear set 64, a pulley transmission group 65, a biaxial support shaft 66, and a second transmission rod 67 , runner 68, reciprocating sleeve 69, rotating column 691, second support shaft 692 and reciprocating rod 693, three first support shafts 63 are connected at intervals on the right side of the top of the support table 1, and the first support shaft 63 is connected with the discharge mechanism 7 , the first transmission rod 62 is rotatably connected between the first support shafts 63, the left side of the first transmission rod 62 passes through the extrusion frame 3, and the first transmission rod 62 is connected to the output shaft of the motor 5 on the left side. The bevel gear set 61, the right side of the top of the support table 1 is connected with a biaxial support shaft 66, the...

Embodiment 3

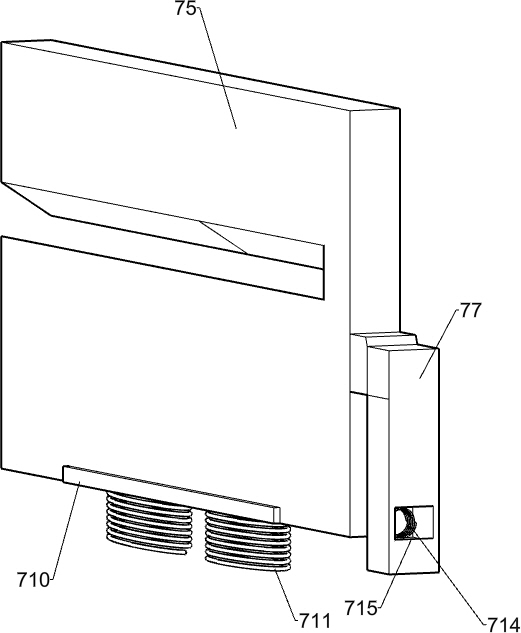

[0067] On the basis of Example 2, such as Figure 4-12 As shown, the discharge mechanism 7 includes a guide frame 71, a discharge frame 74, a grooved baffle 75, a connection block 77, a support block 78, a placement frame 79, a limit block 710, a first spring 711, and an extrusion block 712. , extrusion rod 713 and second spring 714, support table 1 top middle rear side is connected with guide frame 71, guide frame 71 is positioned at the left side of second support shaft 692, guide frame 71 top has first guide groove 73, guide frame There are second through holes 72 on the left and right sides of the upper part of 71, the second through holes 72 communicate with the first guide groove 73, the upper part of the front side of the guide frame 71 is connected with a placement frame 79, and the tops of the two first support shafts 63 on the left side Support blocks 78 are all provided, and a discharge frame 74 is connected between the tops of the support blocks 78, the rear side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com