Damping spring grouping assembling device for clutch damping spring assembling machine

A technology for damping springs and assembling devices, which is applied to devices for coating liquid on surfaces, sorting, metal processing, etc., can solve the problems of affecting measurement results and low measurement accuracy of measurement equipment, and achieves uniform coating effect and fast measurement. , grouping accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

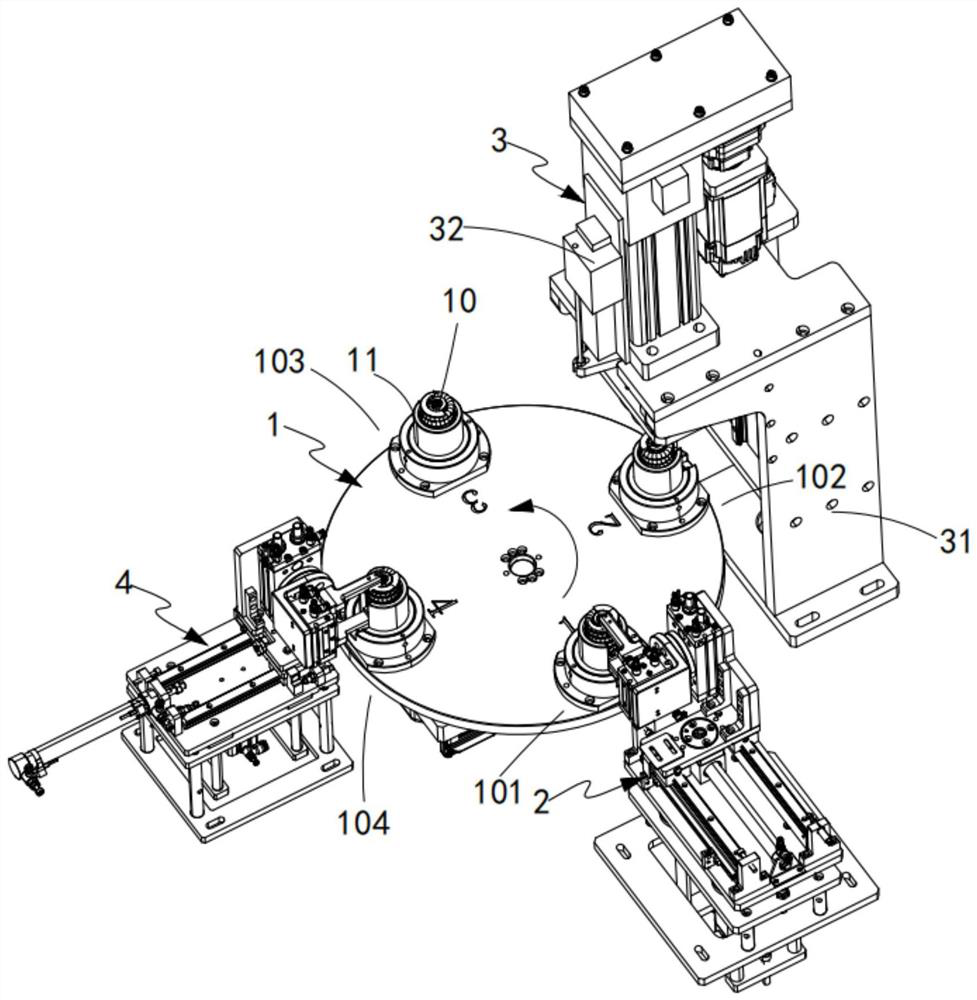

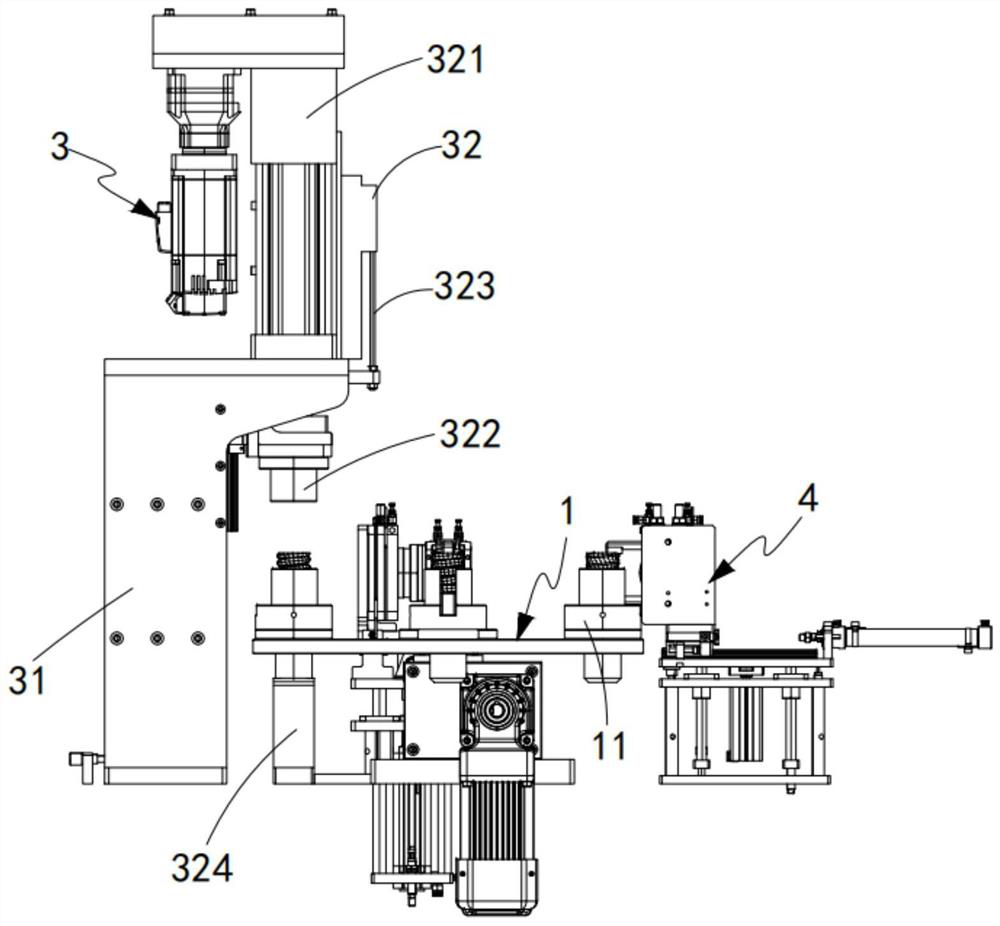

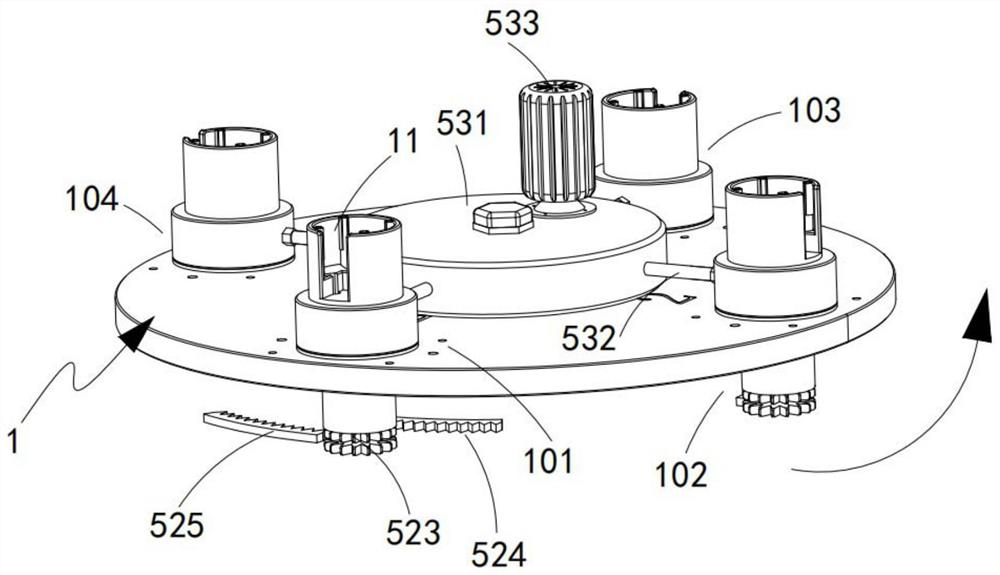

[0073] Such as Figure 1 to Figure 9 As shown, a shock absorbing spring group assembly device for a clutch shock absorbing spring assembly machine includes a turntable 1, and a plurality of positioning mechanisms 11 are equidistantly distributed on the circumference of the turntable 1, and the positioning mechanism 11 is provided with load-absorbing In the cavity 12 of the shock spring 10, a feeding station 101, a compression detection station 102, a transfer station 103, and a discharge station 104 are arranged equidistantly in the direction of rotation of the turntable 1, and also includes:

[0074] Feeding mechanism 2, said feeding mechanism 2 is installed adjacent to said turntable 1, it is located at said loading station 101, and it is used to clamp said shock absorbing spring 10 and place it vertically in said space Inside chamber 12;

[0075] A compression measurement mechanism 3, the compression measurement mechanism 3 is installed adjacent to the turntable 1, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com