Needle inserting worktable for micro needles

A workbench and pin insertion technology, applied in workbenches, manufacturing tools, TVs, etc., can solve problems such as time-consuming and labor-intensive difficulty, low efficiency, and difficulty in eliminating omissions or misplaced points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

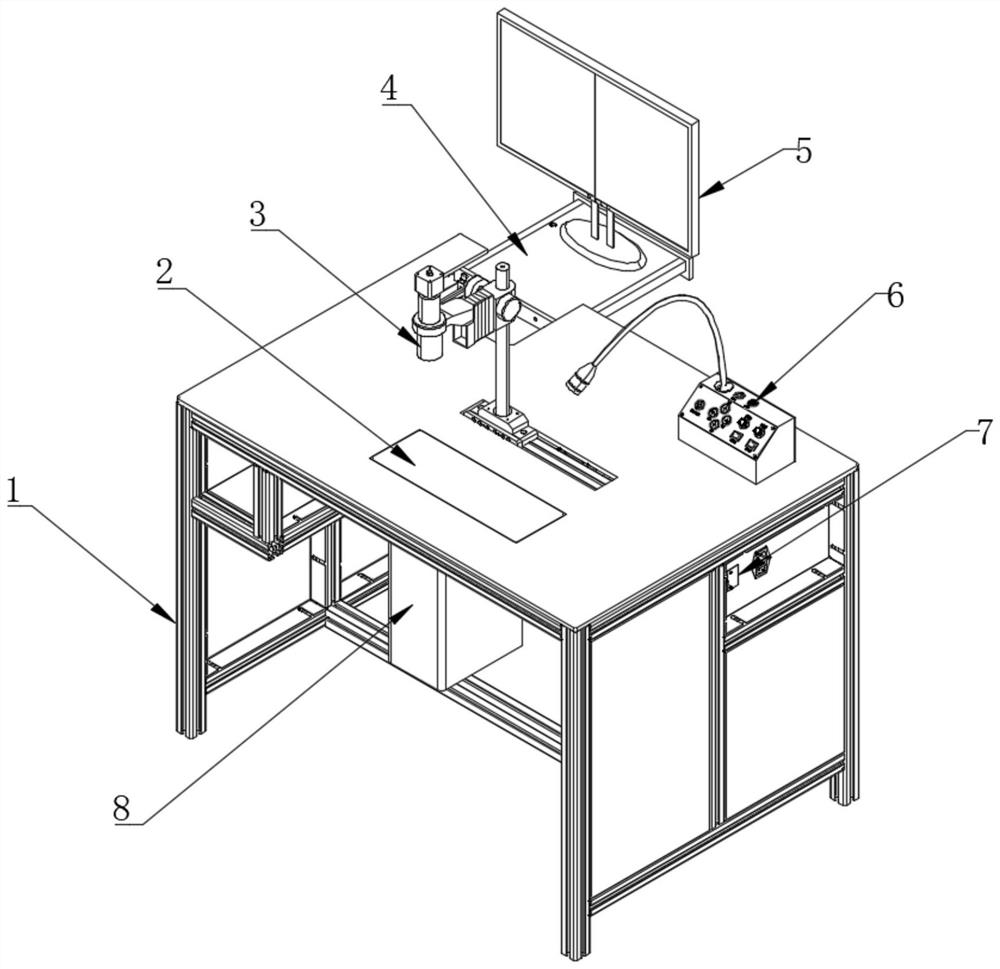

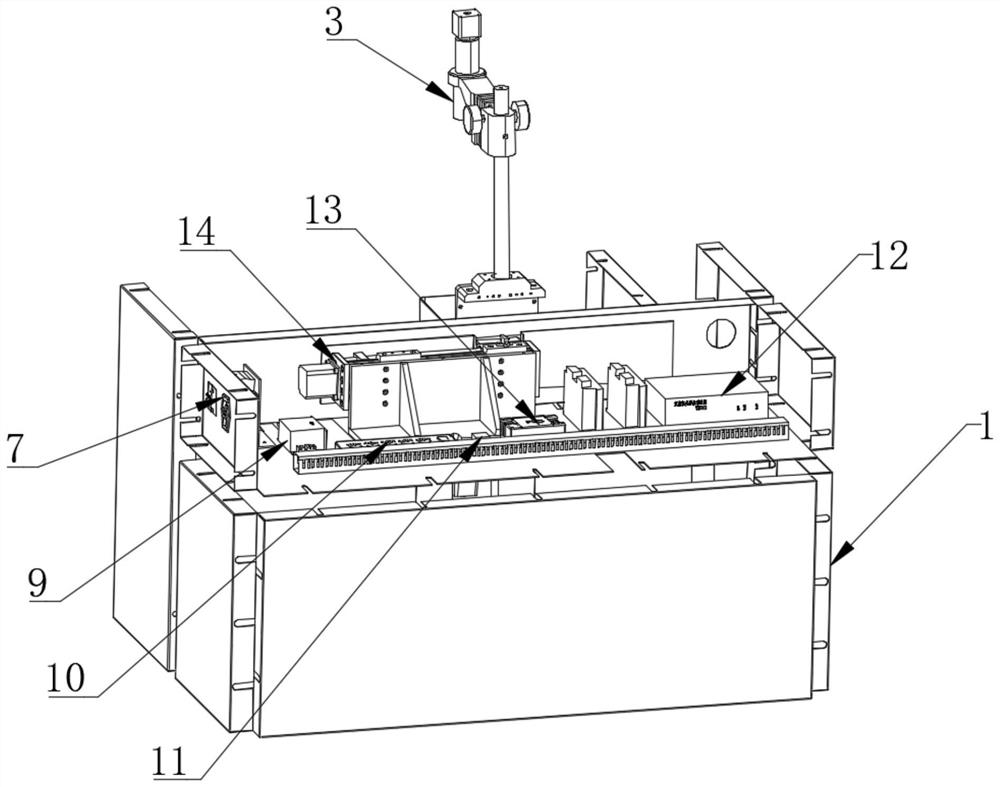

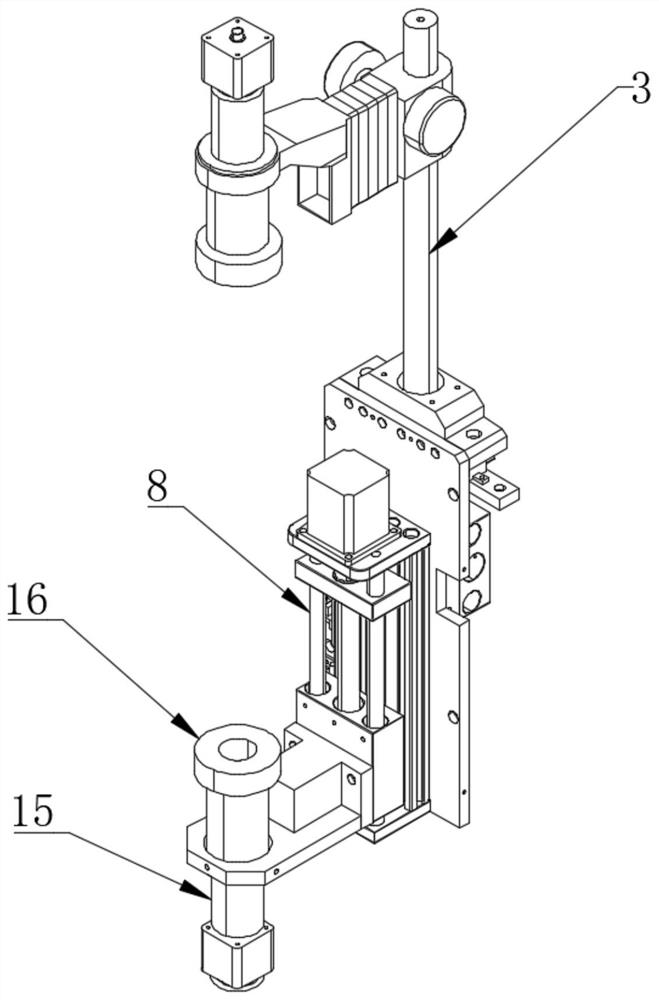

[0025] see Figure 1-8 , in an embodiment of the present invention, a microneedle insertion workbench includes a workbench body 1, a telescopic workbench 4 is slidably connected to the rear side of the upper end of the workbench body 1, and the upper end of the workbench body 1 is far away from the retractable workbench. One side of the table 4 is equipped with a console button centralized control module 6, the middle part of the workbench body 1 is embedded with an upper camera assembly 3, and the upper end of the workbench body 1 is provided with a transparent observation table 2 near the front side of the upper camera assembly 3, One side of the workbench body 1 is embedded with a main power switch 7, the inner side of the workbench body 1 is located at the rear end of the upper camera assembly 3 and a lateral adjustment mechanism 14 is installed, and the inner side of the workbench body 1 is close to the side of the main power switch 7 A 24V power supply 9 is provided, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap