Material conveying system capable of automatically overturning circulating trolley

A conveying system and self-turning technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem of waste of travel space, and achieve the effect of convenient construction, saving construction cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

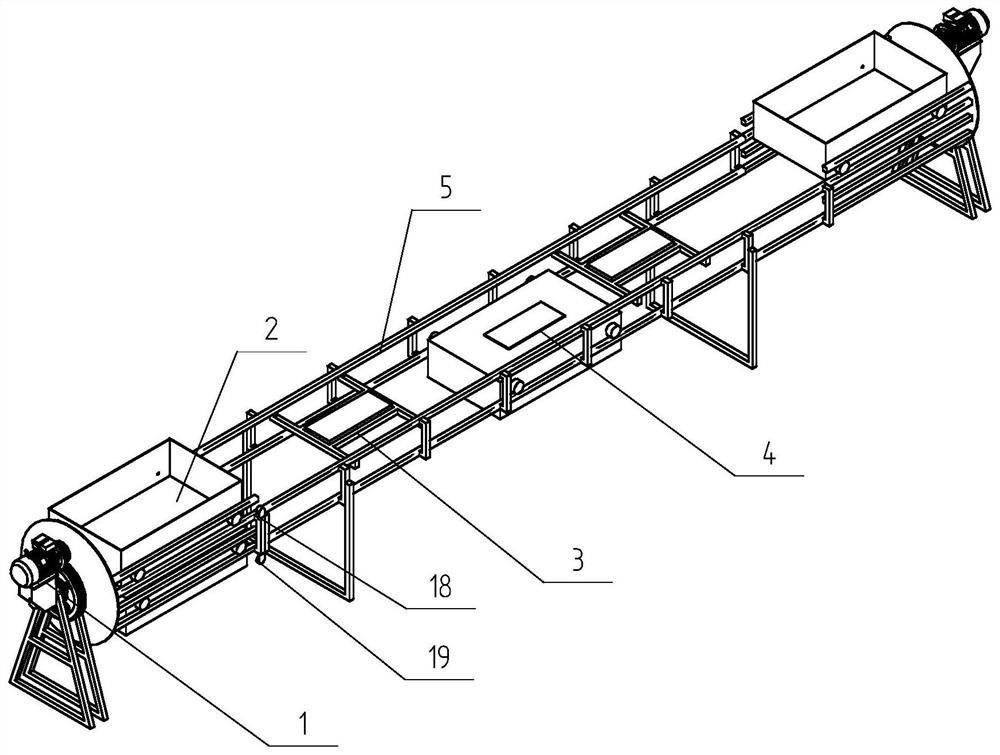

[0057] Example 1.2, as in Image 6 As shown, a material conveying system with a self-turning cycle trolley is different from Example 1.1 in that the conveying track (6) includes several sets of walking guides and drive rail modules (5), and a magnetic power material trolley (2) is added at the same time. The number of modules is applicable to the working conditions with large transportation volume and long distance.

[0058] In the above-mentioned embodiment, the working process of a material conveying system of a self-turning cycle trolley provided by the present invention is as follows: Figure 7 , 8 , 9, the specific description is as follows:

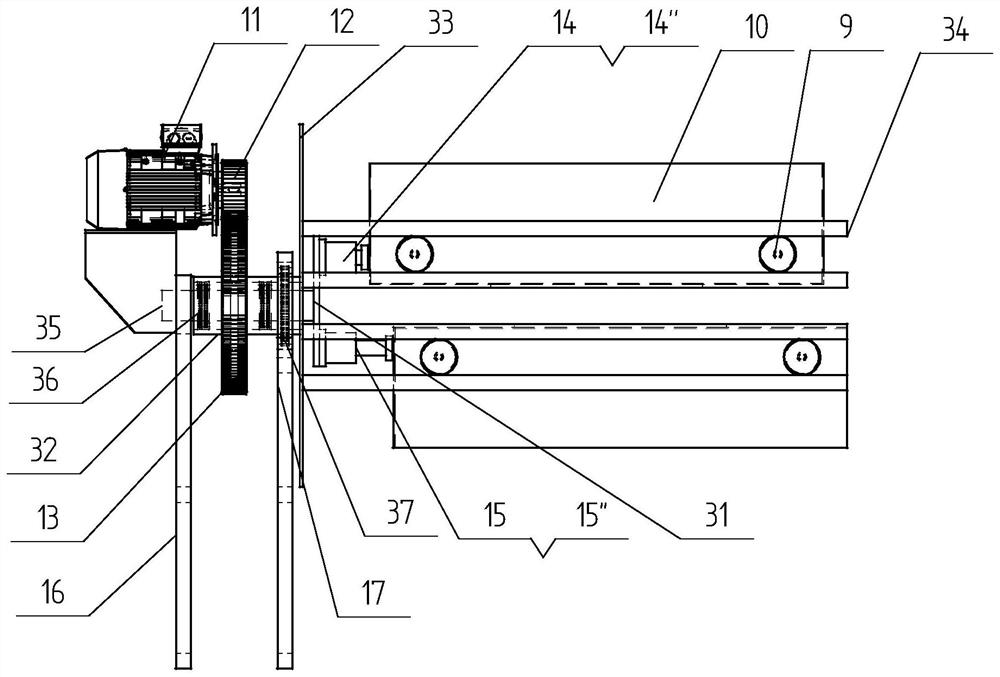

[0059] a) When the empty magnetic power material trolley (2) arrives at the material receiving end along the down track, the entry detection sensor J1 (19) detects a signal, the buffer stroke cylinder solenoid valve A2 (15') is energized, and the buffer stroke cylinder (15') ) is slowly retracted under the impact of the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com