Cabinet equipment installation lifter

A technology for equipment installation and lifts, which is applied in the field of lifts, can solve problems such as maintenance troubles, accidents, and high costs, and achieve the effects of convenient installation and maintenance, increased load capacity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

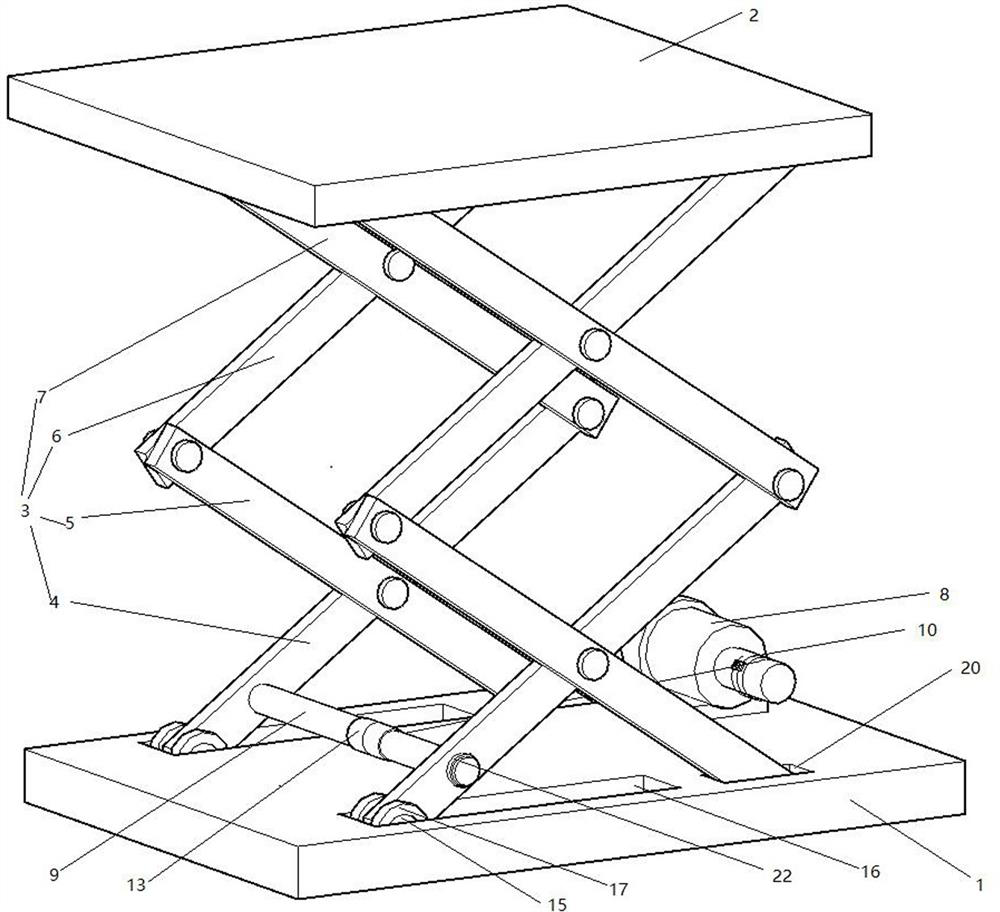

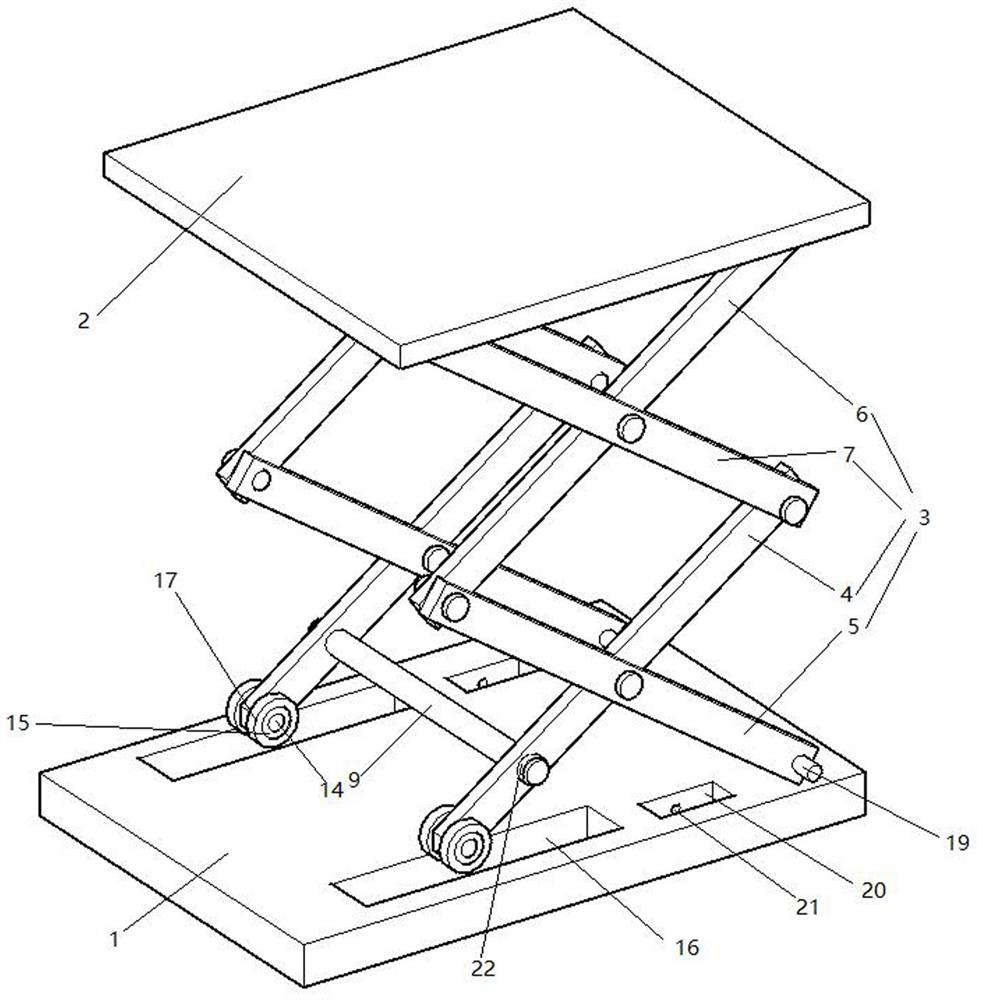

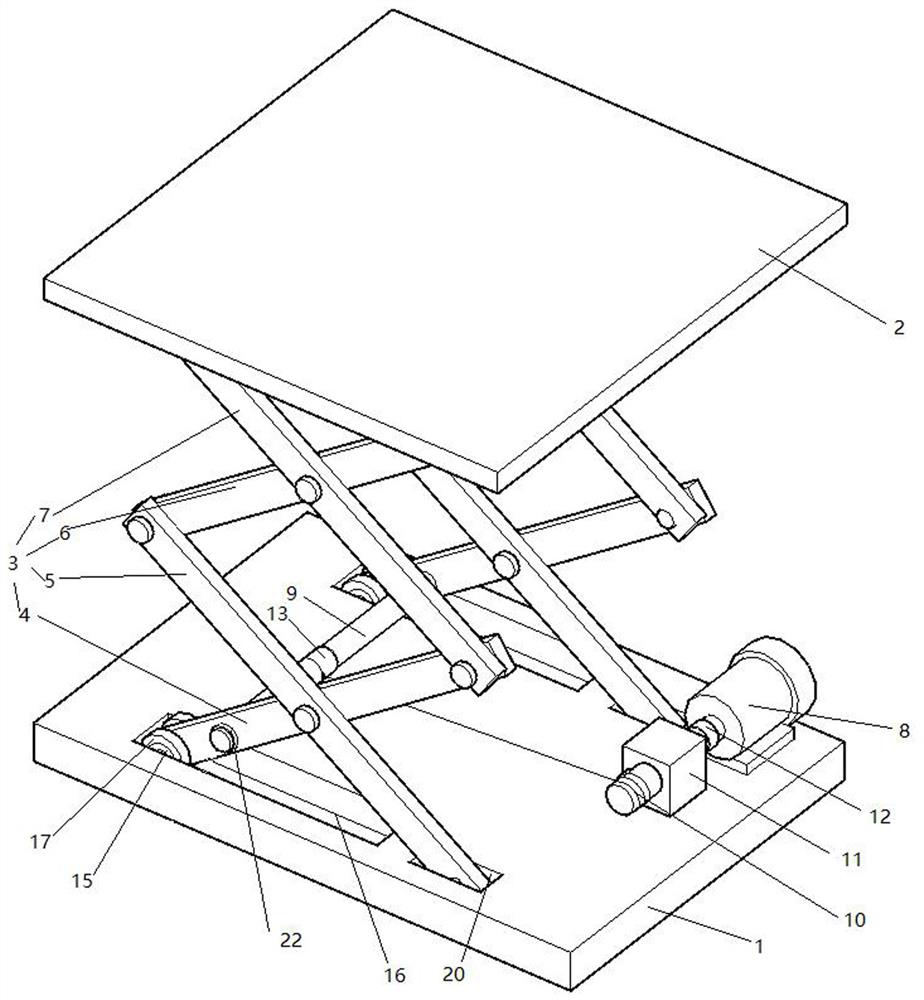

[0031] Such as figure 1 with figure 2 Shown as the first embodiment of the present invention, a cabinet equipment installation elevator includes a base 1, a carrying platform 2, and two sets of scissor-like support arms 3 between the base and the carrying platform. The first connecting rod 4, the second connecting rod 5, the third connecting rod 6 and the fourth connecting rod 7 are hinged to each other in a scissor type. The bottom ends of the first connecting rod 4 are welded with steel connecting shaft 14 respectively. The connecting shaft 14 is provided with a roller 15 outside. The roller 15 is a roller bearing. The inner peripheral surface of the roller 15 is fixed on the connecting shaft 14 by glue or welding. The base 1 is machined by a lathe to match the two rollers 15 Slide groove 16, the outer peripheral surface of the roller 15 is in contact with the bottom surface of the slide groove 16, in order to increase the friction between the roller 15 and the slide groove 1...

Embodiment 3

[0036] Such as Figure 4 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the ends of the two connecting shafts 14 are respectively fixed by bolts to the universal ball 18, the universal ball 18 and the sliding groove 16 The two side walls are in contact.

Embodiment 4

[0038] Such as Figure 5 Shown is the fourth embodiment of the present invention. The difference between this embodiment and the first embodiment is that a bearing 23 is provided on the connecting shaft 19, the bearing 23 is a roller bearing, and the inner circumferential surface of the bearing 23 is fixed by glue On the outer peripheral surface of the connecting shaft two 14, the part above the insertion hole 21 is then cut off by a cutting machine, the outer circumferential surface of the bearing 23 is fixed to the inner peripheral surface of the insertion hole 21 with glue, and then the cut part is glued with glue Back.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com