Multifunctional glass cutting machine

A cutting machine, multi-functional technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large cutting error, complex cutting process, slow processing speed, etc., to achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

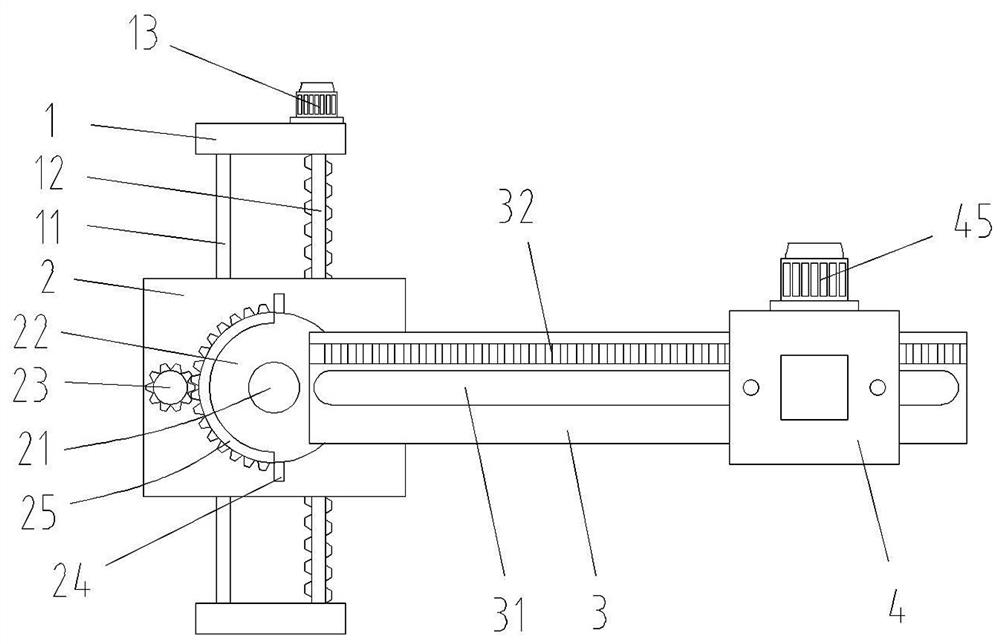

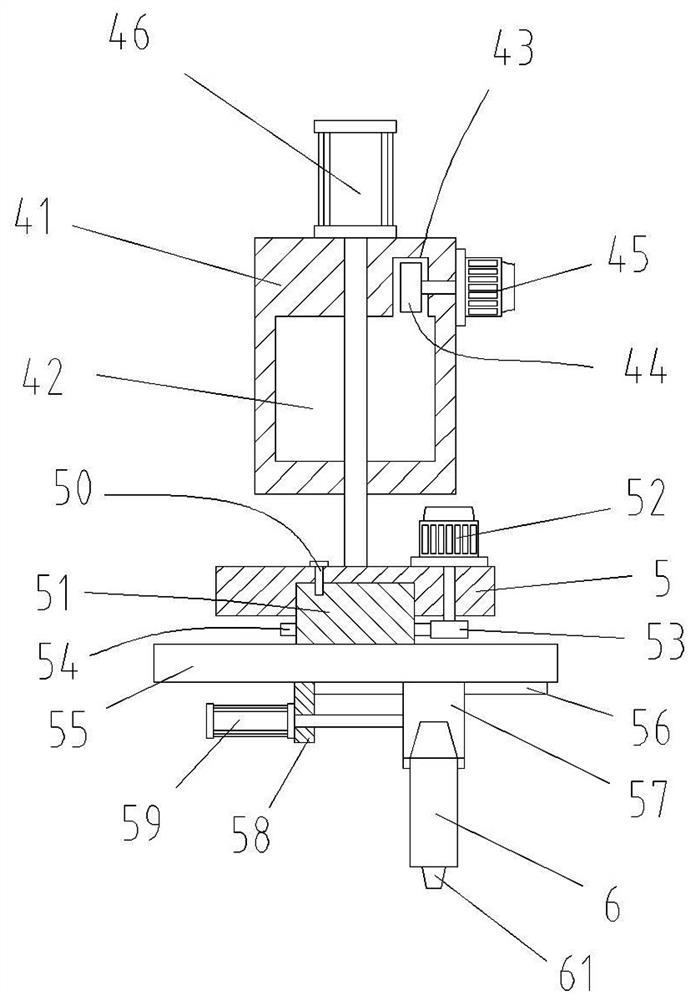

[0018] Such as Figure 1-2 As shown, a multifunctional glass cutting machine provided by the present invention includes two vertical plates 1 arranged in parallel, a guide shaft 11 is fixedly connected between the two vertical plates 1, and a slide plate 2 is slidably connected to the guide shaft 11. Also be provided with the first power device that is used to control slide plate 2 to slide along guide shaft 11 between vertical board 1, first power device comprises screw mandrel 12, and screw mandrel 12 is connected in rotation between two vertical boards 1, slide plate 2- The side is provided with screw threaded hole, and screw mandrel 12 passes in the screw screw threaded hole and is threadedly connected in screw screw threaded hole, and the second motor 13 is fixedly connected on one side of one of the vertical plates 1, and the main shaft of the second motor 13 It is coaxially fixed with the screw mandrel 12.

[0019] The fixed shaft 21 is fixedly connected to the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com