Fluidized bed gasification furnace deslagging method and device

A fluidized bed gasifier and gasifier technology, which are applied in the field of coal gasification, can solve the problem that the bed height of the gasifier cannot be maintained constant, the slag bucket is overheated, and the safety and stability of the pressurized fluidized bed gasifier cannot be realized. Slag discharge and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

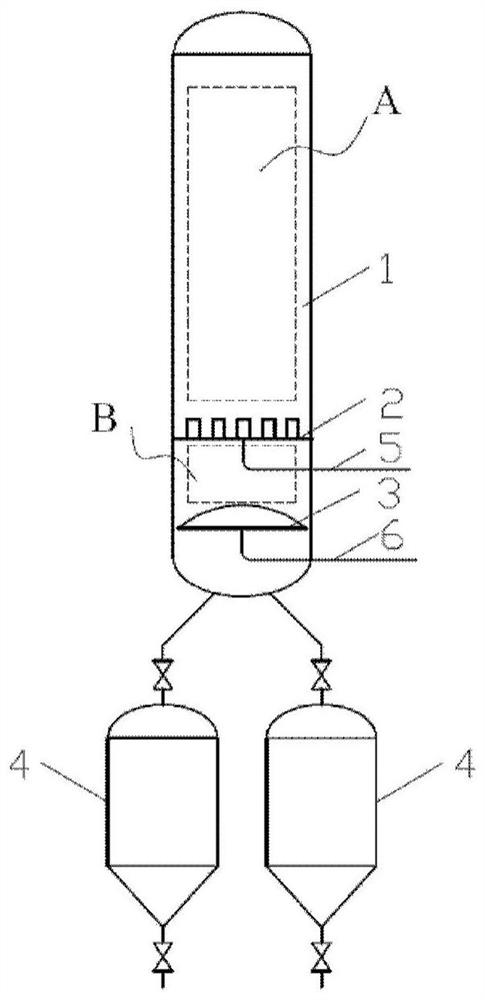

[0061] In Embodiment 1 of the present invention, a fluidized bed gasifier slagging device is provided, such as figure 1 As shown, the device used includes a gasifier 1, a slag hopper 4 and a gasification agent air distribution device 2 located at the lower part of the gasifier 1. The gasifier 1 and the slag hopper 4 are connected through a slag discharge pipe, and also include : the ash and slag cooling zone B arranged at the lower part of the air distribution device 2, the slag discharging machine 3 arranged in the ash and slag cooling zone B, the slag discharging machine 3 is provided with an air distribution pan 10 for feeding cooling gas. The gasification agent required for the gasification reaction is introduced into the air distribution device 2 through the main air pipe 5 and then passed into the gasification furnace 1 . The cooling gas passes into the slag discharger 3 through the cooling air pipe 6, and enters the ash cooling zone B from the air distribution pan 10 of...

Embodiment 2

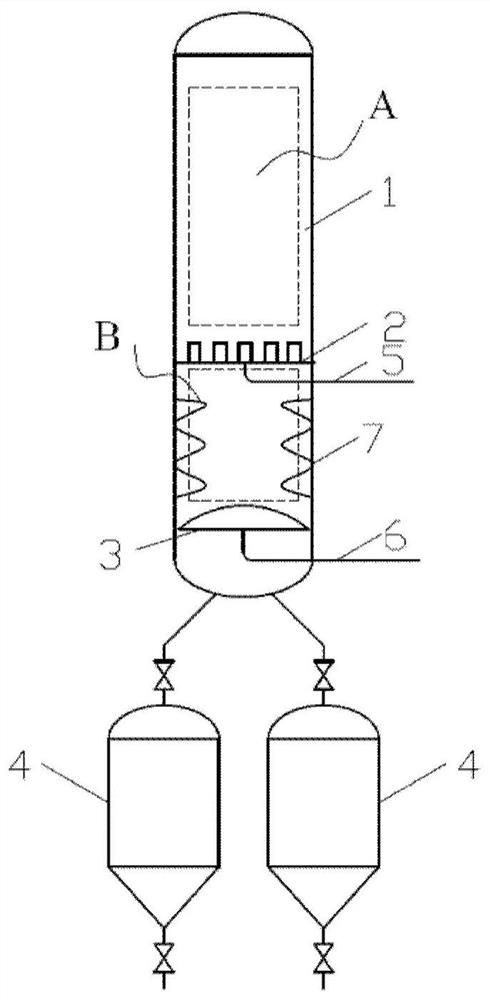

[0065] Such as figure 2 As shown, the fluidized bed gasifier slagging device provided by Example 2 of the present invention has the same structure as that of Example 1, the difference is that in order to better realize ash cooling, heat exchange is arranged in the ash cooling zone B The tubes 7 and the heat exchange tubes 7 can be arranged tubes or serpentine tubes. From the perspective of facilitating material drop and wear resistance, serpentine heat exchange tubes with fins are preferred. The heat exchange tubes 7 are arranged in multiple groups along the circumferential direction. In order to prevent slag from bridging on the heat exchange tubes 7, the distance between two adjacent groups of heat exchange tubes 7 is 80mm-150mm. In order to prevent steam from condensing on the wall of the heat exchange tube 7, the cooling gas in the heat exchange tube 7 is preferably synthesis gas. From the perspective of reducing the wear of the heat exchange tube 7, the superficial veloc...

Embodiment 3

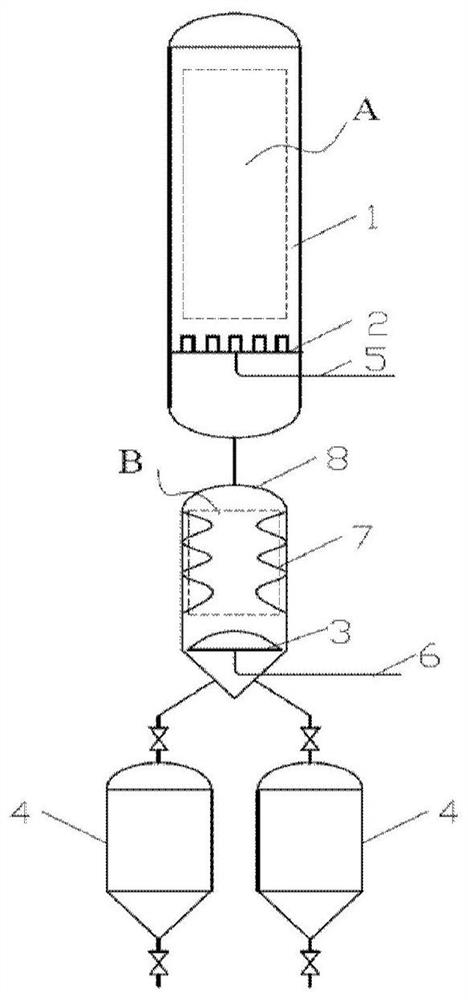

[0067] Such as image 3 As shown, the fluidized bed gasifier slagging device provided in Example 3 of the present invention has the same structure as that of Example 1, the difference is that the ash is cooled by the slag cooler 8, and snakes are arranged inside the slag cooler 8. A slag discharger 3 is installed at the bottom, and the slag cooler 8 is connected to the gasifier 1 through the slag discharge pipe. The hot ash generated by gasification enters the slag cooler 8 through the slag discharge pipe, The cooling gas is in countercurrent contact, and under the disturbance of the cooling gas, it rapidly exchanges heat with the heat exchange tube to obtain cooling (the process flow is the same as that of Example 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com