Blast furnace iron runner erosion detection system and method

A detection method and detection system technology, applied in the direction of inspection devices, discharge devices, etc., can solve the problems of easy damage of temperature sensors, low accuracy of appearance monitoring, and susceptibility to interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

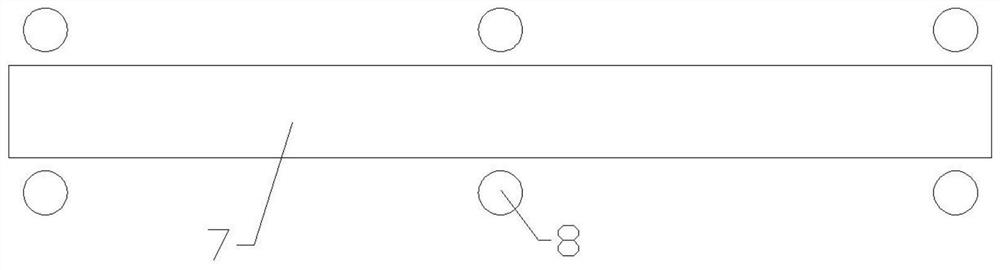

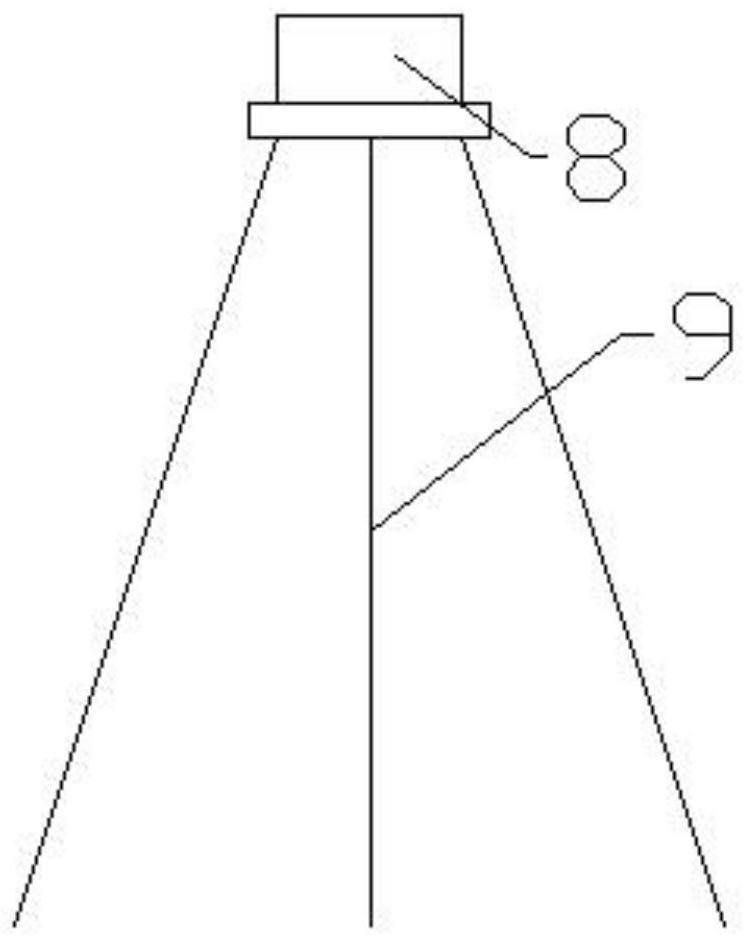

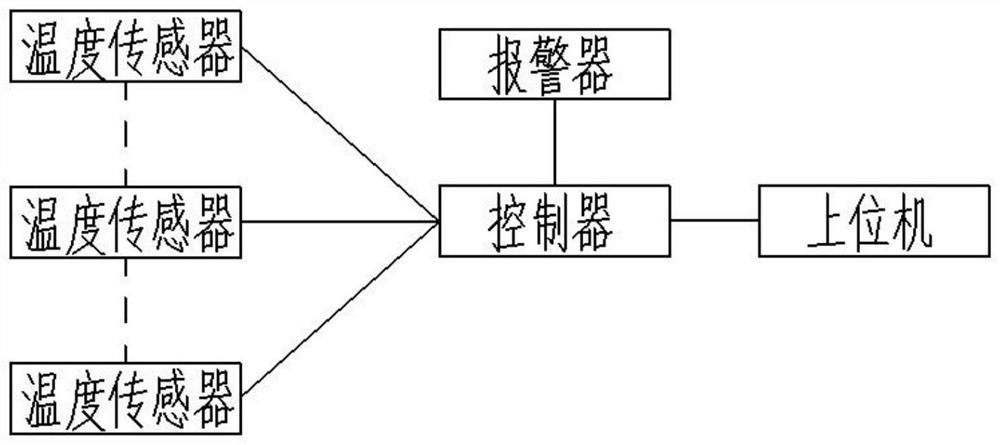

[0028] Such as Figure 1-8 As shown, a blast furnace iron trench erosion detection system includes an image acquisition device and a server. The image acquisition device includes a bracket 9, and a 3D scanner 8 is installed on the upper end of the bracket. The 3D scanner is connected to the server signal, and the image acquisition device can be used from multiple Image acquisition is performed on the iron trench from different angles, and the server is a PC. Specifically, the 3D scanner has at least 6 scanning points. Overlay 3D scanning to get a complete 3D model.

[0029] After the production of the new iron trench is completed, and after each tapping is completed and the residual iron is placed, 3D scanning is carried out, and the 3D model of the working face of the iron trench is converted from the image obtained through the 3D scanning. By comparing the 3D models in each The coordinate change value of the point is obtained to obtain the erosion value of the iron trench. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com