Amorphous crsicn coating and its preparation method, application, conductive film and electronic device

An amorphous, conductive film technology, applied in the direction of application, coating, metal material coating technology, etc., can solve the problems of inability to meet the needs of intelligent electronic equipment, poor hardness and wear resistance, and reduced service life, and achieve the goal of coating The structure is compact, the corrosion resistance is resistant, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] An embodiment of the present invention provides a method for preparing an amorphous CrSiCN coating, including the following step S100.

[0046] S100. Under vacuum conditions, a CrSi alloy target is used as the target material, and inert gas, C 2 H 2 and N 2 , carry out vapor deposition to obtain amorphous CrSiCN coating;

[0047] Wherein, the above-mentioned vapor deposition adopts ion source-assisted deposition.

[0048] The technical personnel of the present invention have taken a new approach on the basis of previous research, using rSCi alloy target as the target material, feeding inert gas, C 2 H 2 and N 2 , and vapor deposition is performed to obtain an amorphous CrSiCN coating; wherein, the vapor deposition adopts ion source-assisted deposition. Using CrSi alloy target, with C 2 H 2 and N 2 After the reaction, the amorphous CrSiCN coating is obtained by deposition, which can avoid the formation of crystalline CrSiCN with columnar morphology, and the use ...

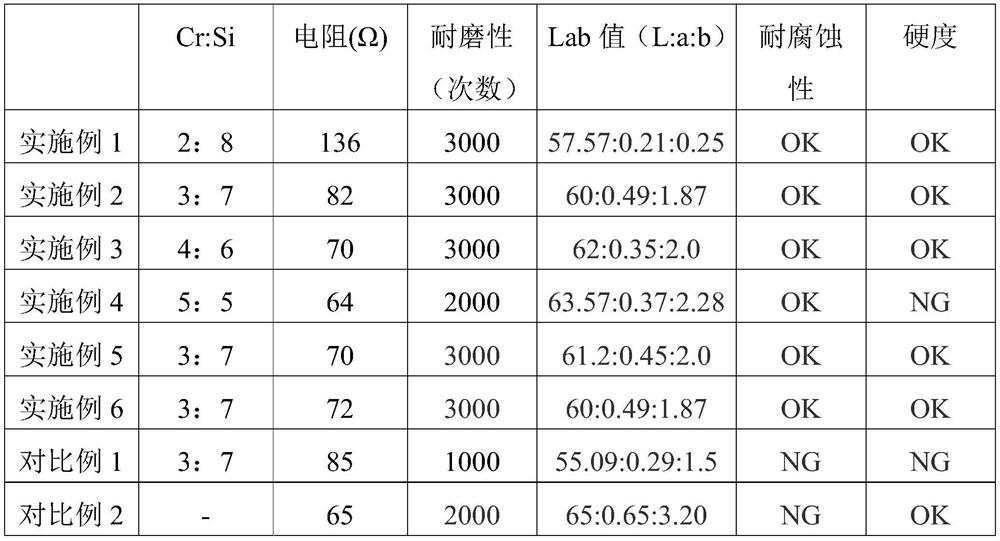

Embodiment 1~4

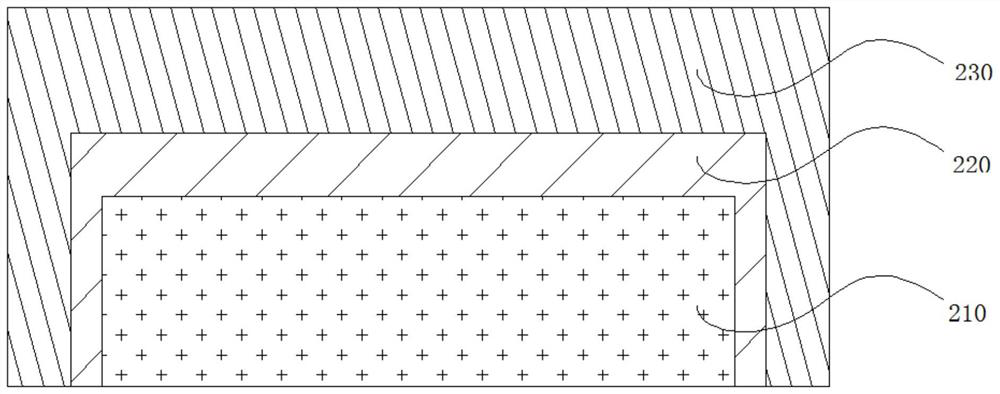

[0090] The process conditions of Examples 1 to 4 are basically the same, and the only difference is that in step 4) the atomic ratio of Cr and Si in the CrSi alloy target (referred to as Cr:Si), the specific atomic ratio is shown in Table 1. The obtained amorphous For CrSiCN coating, please refer to appendix figure 1 ,Specific steps are as follows.

[0091] 1) Provide a base material 210, the base material 210 includes a front surface 211 and a reverse surface 212, the material of the base material 210 is glass, and the following coating operations are performed on the front and back sides respectively. The front surface 211 is the skin contact surface of the smart wearable device, and the front surface 211 is the electrical signal reading surface.

[0092] 2) Plasma cleaning of the substrate 210 in a vacuum environment: the substrate 210 is placed in a vacuum environment in a PVD furnace for ion cleaning, and the ion cleaning process parameters: the vacuum pressure is not hi...

Embodiment 5

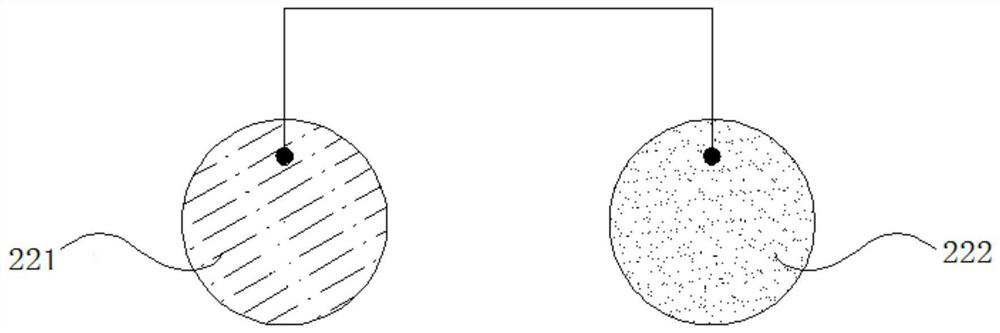

[0096] Example 5 is basically the same as Example 1, except that in step 4) of Example 5, a CrSi alloy target and a hot isostatic Cr target are used for mixed sputter deposition. Among them, the target power of the hot isostatic pressing Cr target is 1kW, and the other process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com