Bagged gravel fence construction method

A construction method and a technology for sand and gravel, which are applied in the field of bagged sand and gravel edge construction, and can solve problems such as difficulty in quickly clearing roads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

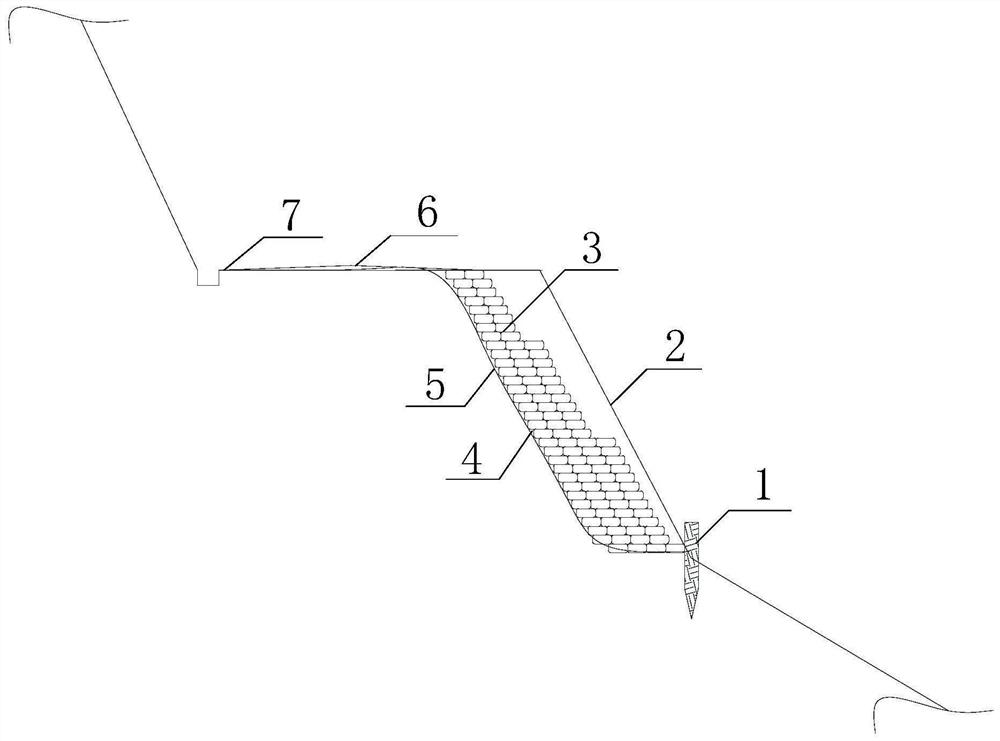

[0040] Such as figure 1 Shown, a kind of bagged gravel sidewall construction method comprises the following steps:

[0041] S1. Preparation of bagged sand and gravel 3: use a small excavator or a shovel to fill the bag with filler, the filler is a mixture of soil, sand and gravel, wherein the particle size of the gravel is Less than or equal to 10cm, the distance between the collapsed gaps in the mining site of the filling is less than or equal to 5km, the volume of the filling in the said storage bag is 50-60%, and the filling in the storage bag should not be filled too full, filling After the completion, it is enough to fasten the mouth of the bag with a rope, and the storage bag is a straw bag, or a plastic woven bag or a sack;

[0042] S2. Use a forklift, loader or manually load the bagged soil into the dump truck, and transport the bagged sand and gravel 3 to the vicinity of the collapsed site by the dump truck;

[0043] S3, leveling the bottom of the collapsed gap, tra...

Embodiment 2

[0048] Such as figure 1 As shown, the present embodiment is based on embodiment 1, and the top of the anchor pile 1 described in step S5 is provided with a displacement monitoring system, and the displacement monitoring system includes a displacement module and a communication module for monitoring the displacement data of the anchor pile 1, and the displacement The module uploads the monitoring data to the terminal in real time through the communication module, and the terminal can be a computer.

[0049] The emergency headquarters can know the deformation situation in real time through the terminal. Once the deformation exceeds the critical value, it can call the police, and the emergency headquarters can immediately stop the traffic in this section to avoid safety accidents.

Embodiment 3

[0051] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and also includes step S6:

[0052] Set warning signs and safety barrels on both sides of the collapsed gap section to avoid safety problems caused by passing vehicles rushing out of the road, and put reflective strips on the warning signs and safety barrels to facilitate night warning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com