Assembled under-column foundation

A prefabricated and basic technology, applied in the field of foundation foundation, can solve the problems of many on-site construction processes, low degree of assembly, easy to be affected by the environment, etc., and achieve the effect of simple and fast construction, speeding up the construction progress, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

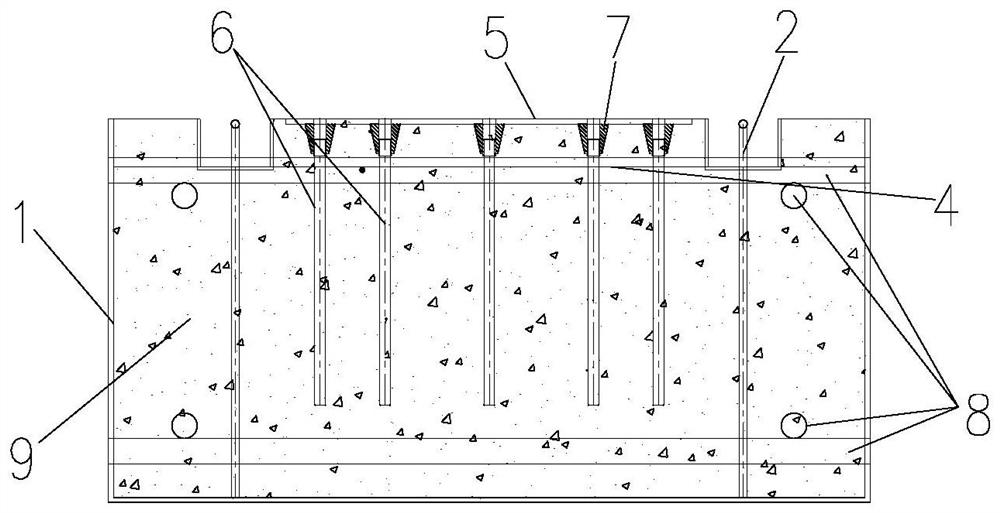

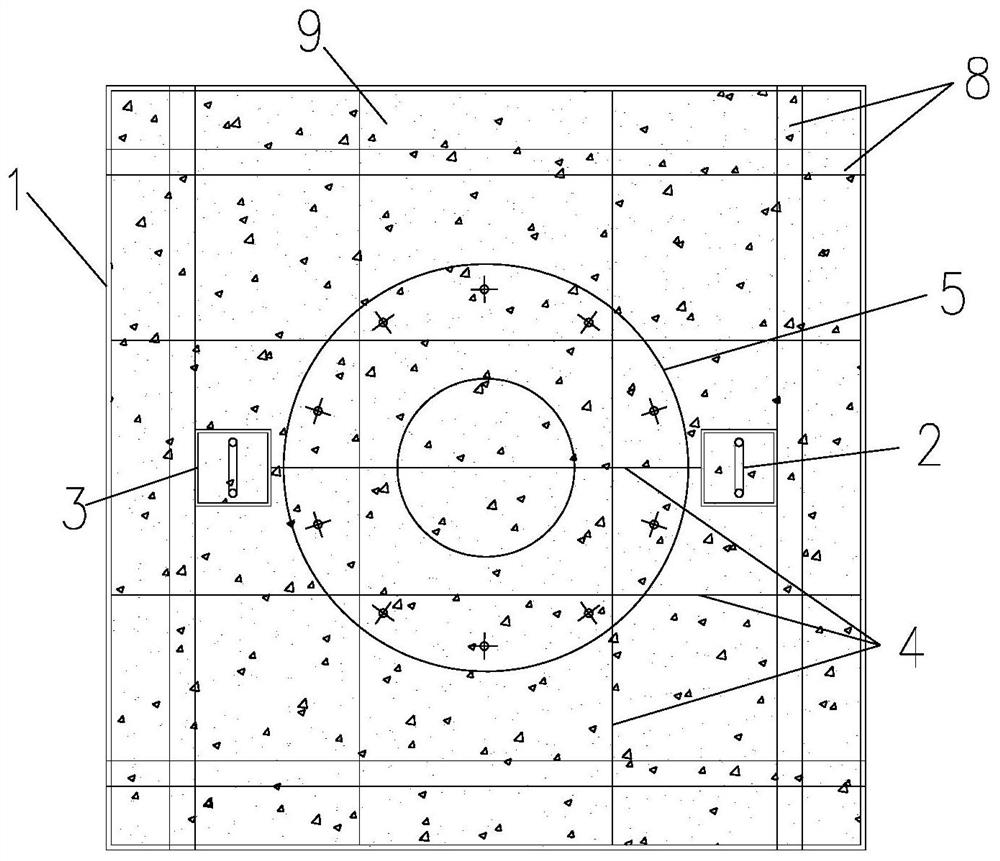

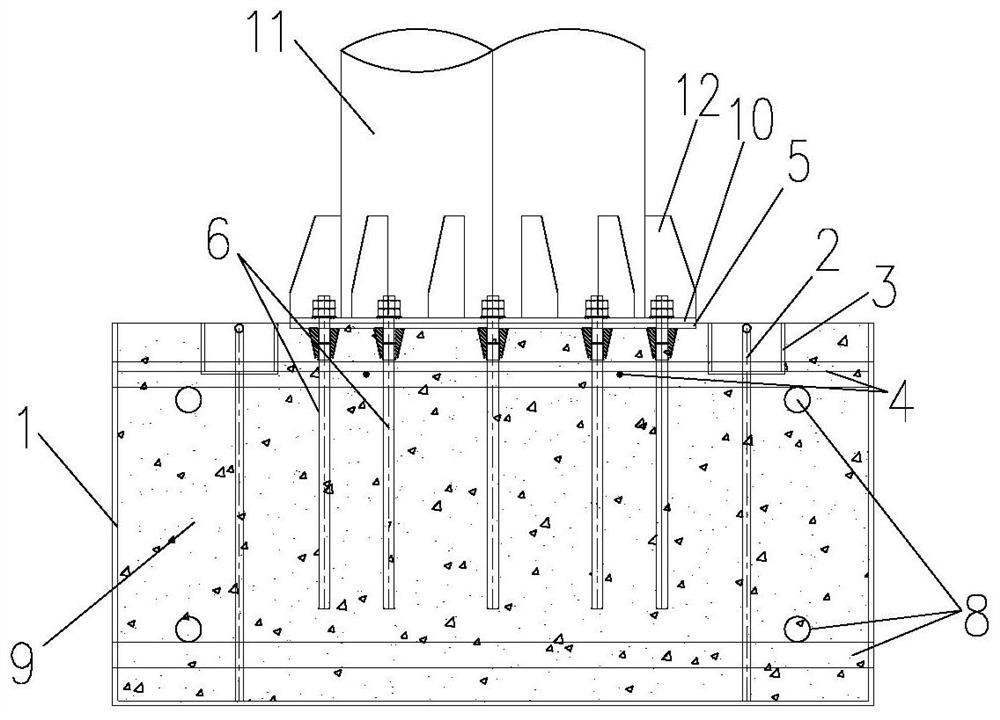

[0019] Such as Figure 1-6 As shown, the assembled sub-column foundation of the present invention includes a box body 1 spliced by weather-resistant steel plates. Vertical tie bars 2 are arranged in the box body 1, and a box made of weather-resistant steel plates is arranged on the top of the tie bars 2. Body 3. The interior of the box body 1 is provided with criss-crossing horizontal reinforcing ribs 4, the interior of the box body 1 is provided with a lower anchor plate 5, a connecting sleeve 7 and an anchor bar 6, the connecting sleeve 7 is welded to the lower end of the lower anchor plate 5, and the anchor bar 6 and the The connecting sleeve 7 is threaded, the lower anchor plate 5 is provided with a bolt connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com