Self-cleaning pressure resistance sliding door device for coal transfer station

A transfer station and self-cleaning technology, applied in the cleaning method using tools, the suspension device of the wing leaf, the arrangement of the leaf leaf, etc., can solve the problems of sliding track wear, sliding obstruction, and easy deformation of sliding doors, etc., to reduce Frictional resistance, the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

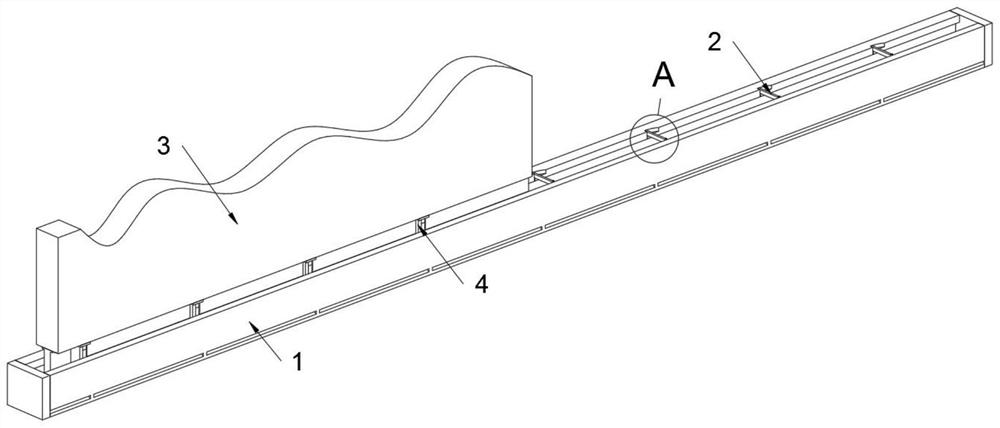

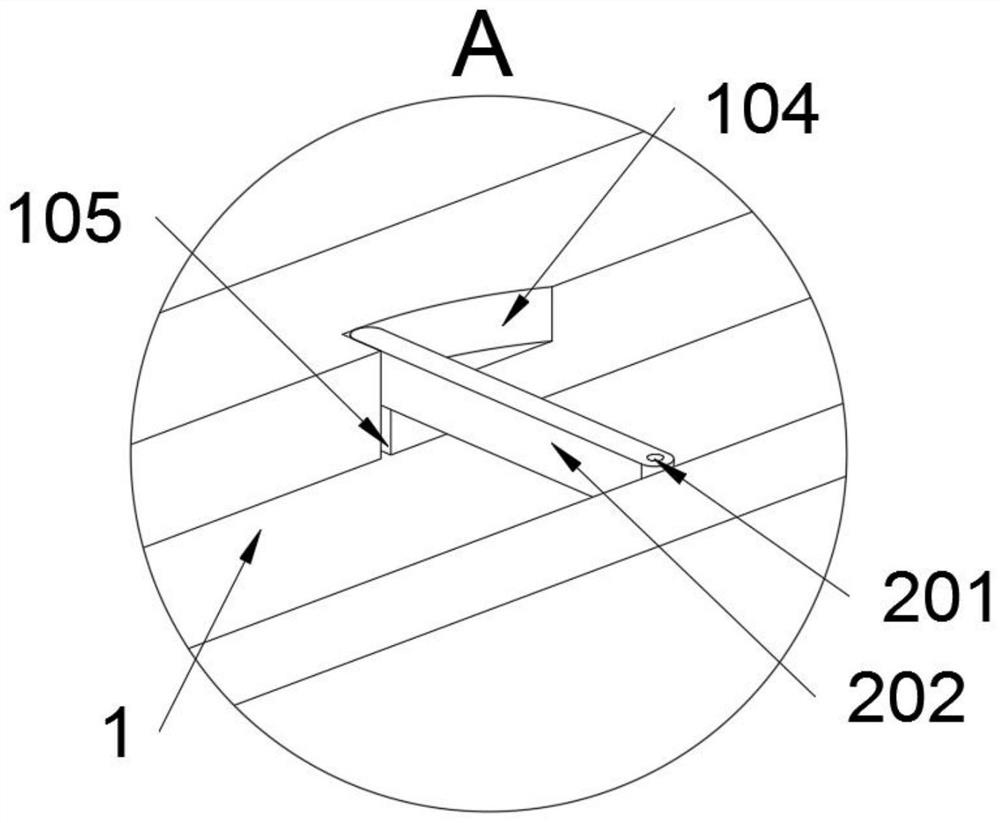

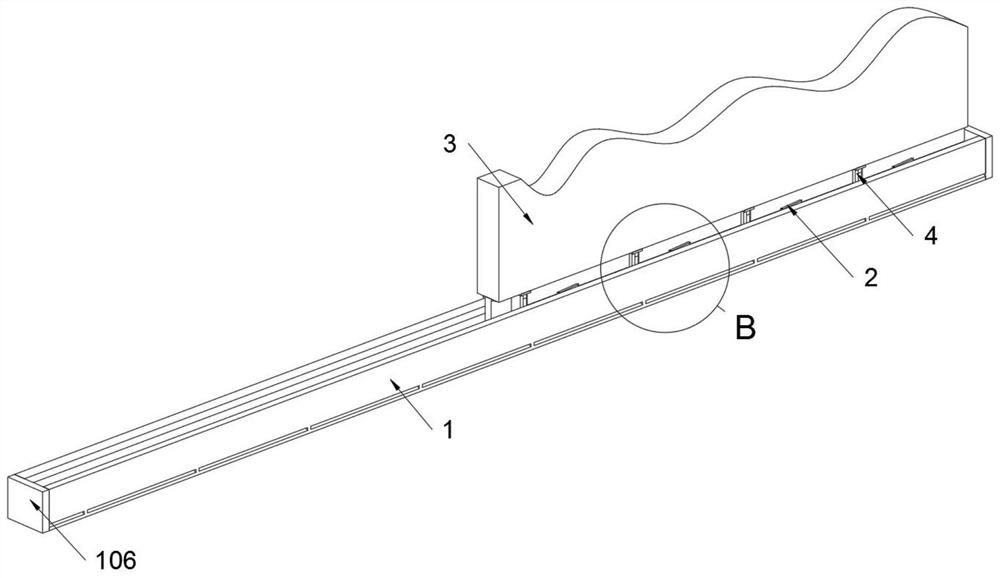

[0037] as attached figure 1 to attach Figure 9 Shown:

[0038] The present invention provides a self-cleaning pressure-resistant sliding door device for a coal transfer station, including a sliding track 1, a door panel 3 and a roller seat 401; the bottom surface of the door panel 3 is fixedly connected with a roller structure 4 in a rectangular array, and the door panel 3 passes The roller structure 4 is slidingly connected in the sliding track 1, and the bottom surface of the door panel 3 is symmetrically fixed with two cleaning structures 5 through bolts; the sliding track 1 is fixed on the ground, and the sliding track 1 is equipped with an elastic support structure 2; refer to for example figure 1 with figure 2 , the elastic support structure 2 includes a rotating shaft 201 and a support arm 202. There are four rotating shafts 201 in total, and the four rotating shafts 201 are all rotatably connected to the sliding track 1, and the tail ends of the four rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com