A High Passability Hydraulic Drilling Rig

A drilling rig and hydraulic technology, which is applied in the field of high-throughput hydraulic excavation drilling rigs, can solve problems such as poor passability of hydraulic excavating drilling rigs, and achieve the effects of improving operation stability and improving passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

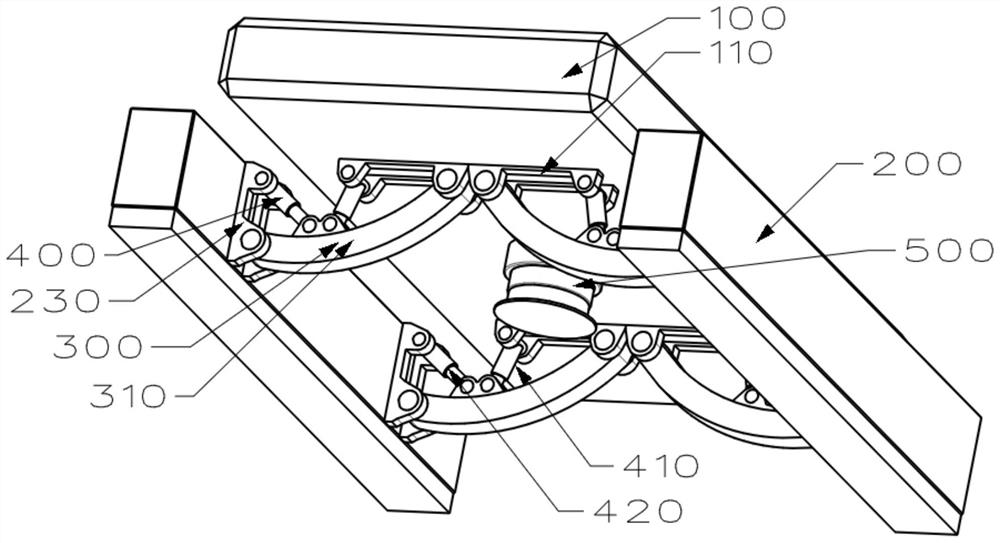

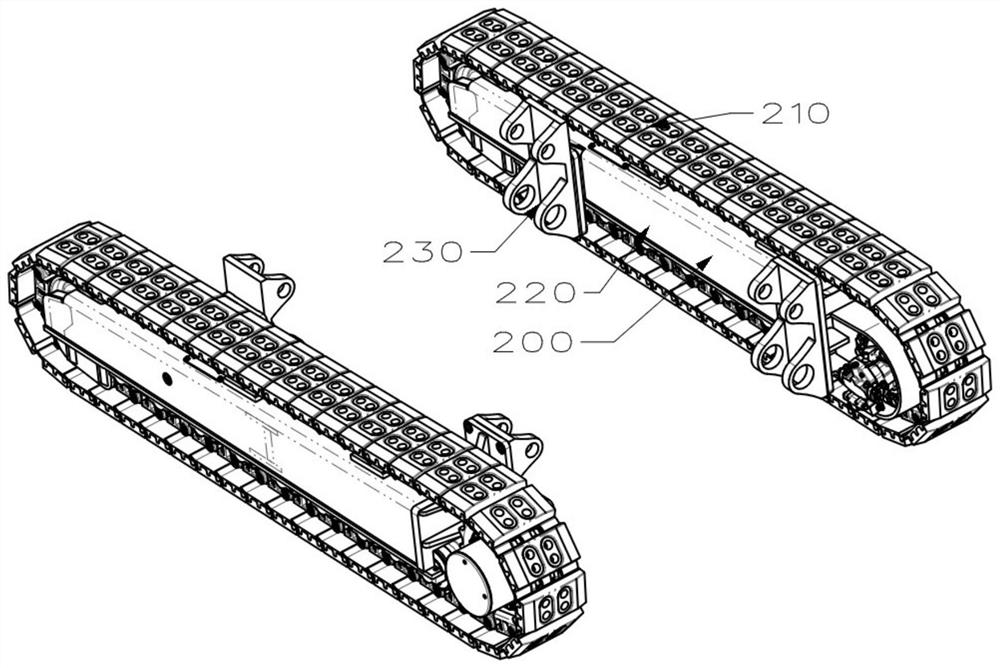

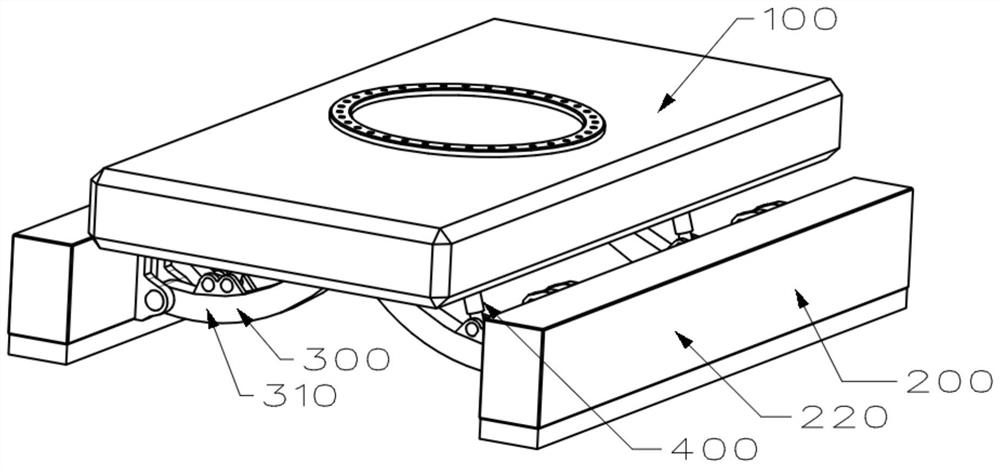

[0075] Such as Figure 1 to Figure 3 As shown, the high-passability hydraulic drilling rig of the present invention includes a chassis main body 100 , a crawler belt assembly 200 , a crawler track positioning plate set 300 , a positioning cylinder set 400 and a lifting support column 500 .

[0076] The chassis main body 100 plays the role of carrying the working parts of the drilling rig and connecting other parts of the chassis of the drilling rig. The structure of the chassis main body 100 can be a rectangular plate or a box structure; the chassis main body 100 includes a positioning assembly 110, The positioning assembly 110 includes a track positioning shoe group positioning assembly and a positioning oil cylinder group positioning assembly. The track positioning shoe group positioning assembly plays the role of hinged the track positioning shoe group 300 and the chassis main body 100, and the positioning oil cylinder group positioning assembly It plays the role of hingedl...

Embodiment 2

[0086] In order to further enhance the passability of the drilling rig and reduce its turning radius; this implementation adds a lifting wheel set 600 on the basis of Embodiment 1; as Figure 6 to Figure 8 As shown, the lifting wheel set 600 is composed of four lifting wheels, which are respectively the first lifting wheel 610, the second lifting wheel 620, the third lifting wheel 630 and the fourth lifting wheel 640; At the bottom of the chassis main body 100, they are symmetrically arranged in groups of two, and a set of lifting wheels corresponds to a lifting support column 500; the first lifting wheels 610 and the second lifting wheels 620 are positioned on the basis of the first lifting wheels The support column 510 is the center of the circle, and the third lift wheel 630 and the fourth lift wheel 640 are positioned on the circle with the second lift support column 520 as the center of the circle; Figure 7 and 8As shown, the traveling direction of the first lifting whe...

Embodiment 3

[0091] Considering that the hydraulic drilling rig sometimes needs short-distance lateral movement during the operation process, but the lateral movement of the existing technology is cumbersome, time-consuming and labor-intensive, and requires a large space (need to repeatedly move backwards and forwards to achieve lateral movement). For the above problems, this embodiment adds an elevator wheel rotation assembly 680 on the basis of the second embodiment, through which the elevator wheel rotation assembly 680 changes the direction of travel of the elevator wheel and then moves the entire road drilling rig; the structure of the elevator wheel rotation assembly 680 Can be a combination of motor and gear.

[0092] Such as Figure 9 As shown, during the operation of this implementation, the drilling rig operator changes the traveling direction of the four lifting wheels through the lifting wheel rotating assembly 680 according to actual needs, and then drives the lifting wheel se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com