Method for blocking bottom water coning

A technology of coning and bottom water, applied in chemical instruments and methods, earth-moving drilling, sealing/sealing, etc., can solve the problems of short validity period, limited sealing range, affecting the effect of oil and water well production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

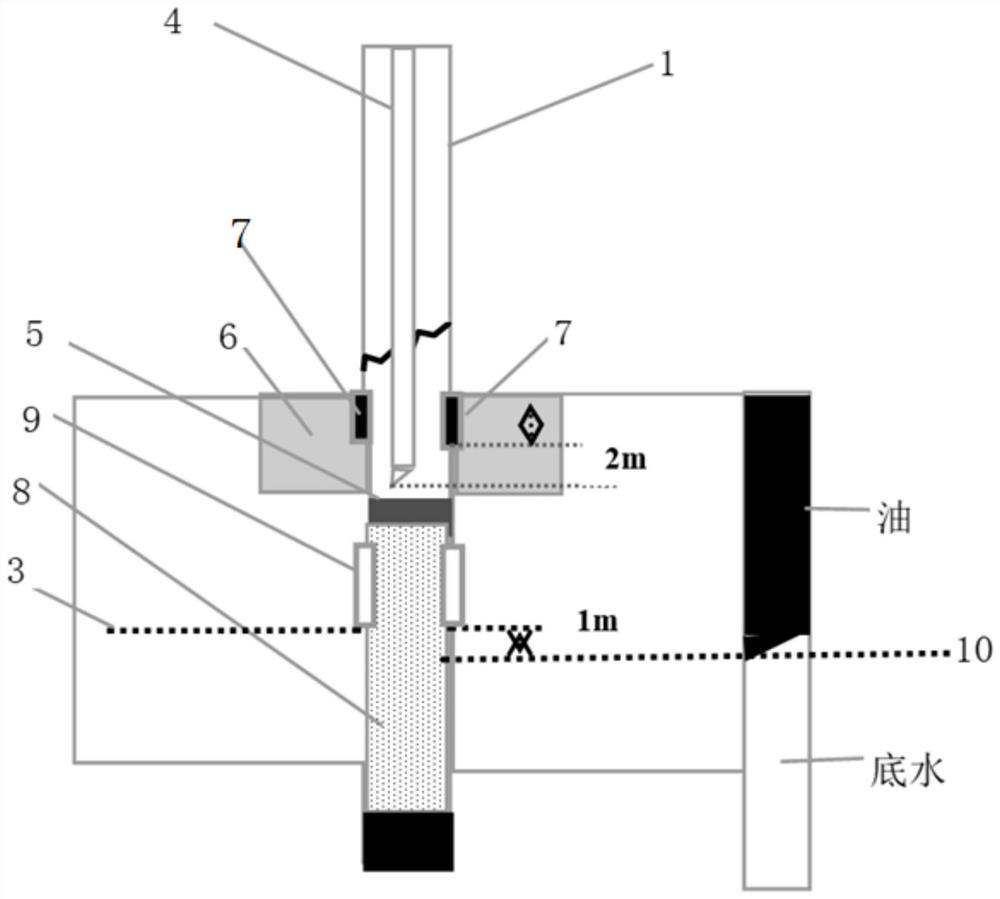

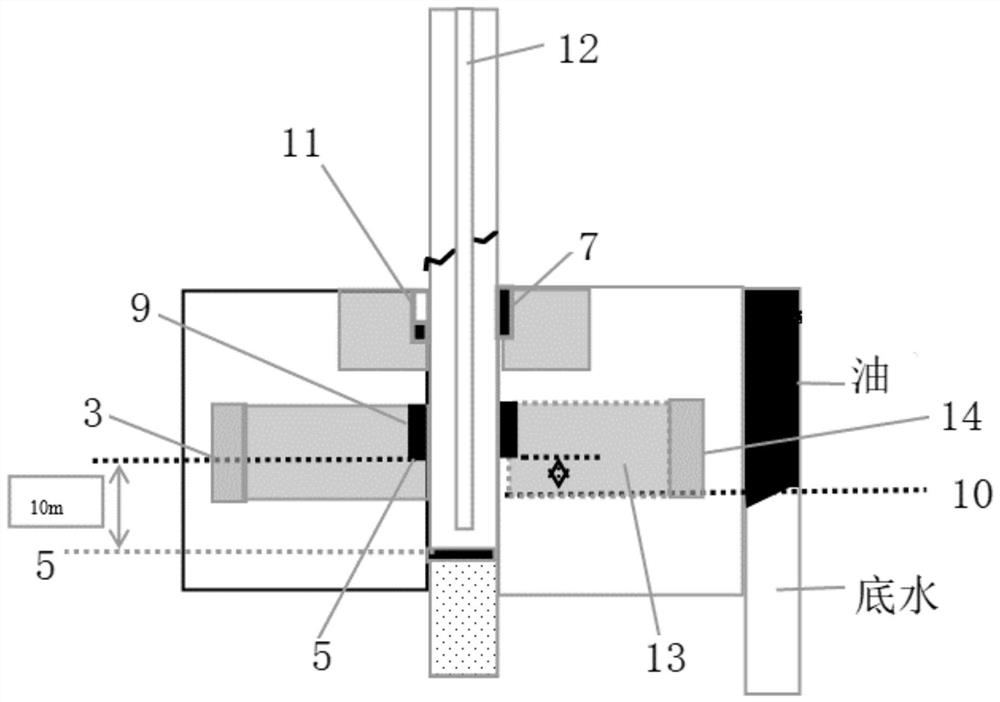

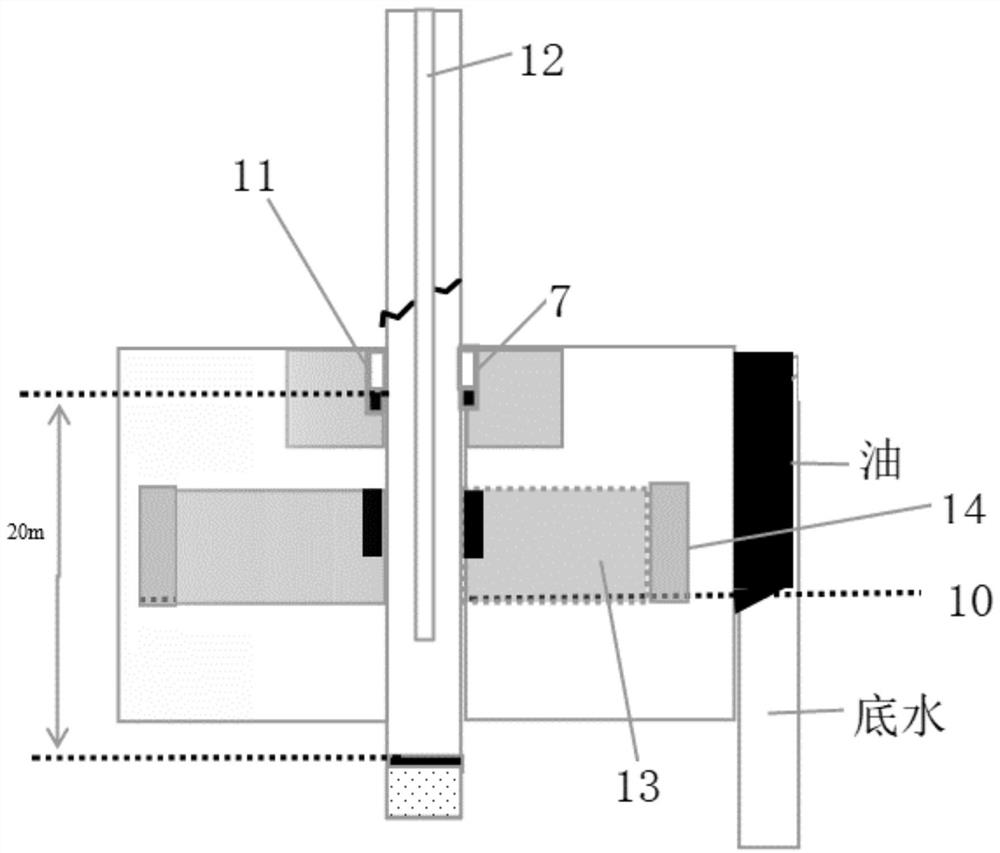

[0040] refer to Figure 1-3 , a method for blocking bottom water coning, comprising the following steps:

[0041] Step 1. According to the original oil-water interface in the oil layer, determine the plugging agent injection position line 3 for plugging bottom water.

[0042] Specifically, the original oil-water interface 10 is determined according to the comprehensive logging chart of the oil well, and the plugging agent injection position line 3 is the preset position on the upper part of the original oil-water interface 10. In this embodiment, the plugging agent injection position line 3 is the original oil-water interface 1m above the interface 10.

[0043] Step 2. Clean the oil well and conduct pressure test and leak detection.

[0044] Specifically, after the wellbore 1 was wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com