Tube-outside packing and coiled tubing combined fracturing method

A technology of tubing and joint operation, applied in the direction of sealing/isolation, drilling pipe, casing, etc., can solve the problems that affect wellbore maintenance and repeated reconstruction, increase the diameter of the pipe string, and increase the construction risk, so as to reduce maintenance and treatment Difficulty and operation risk, low cost, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

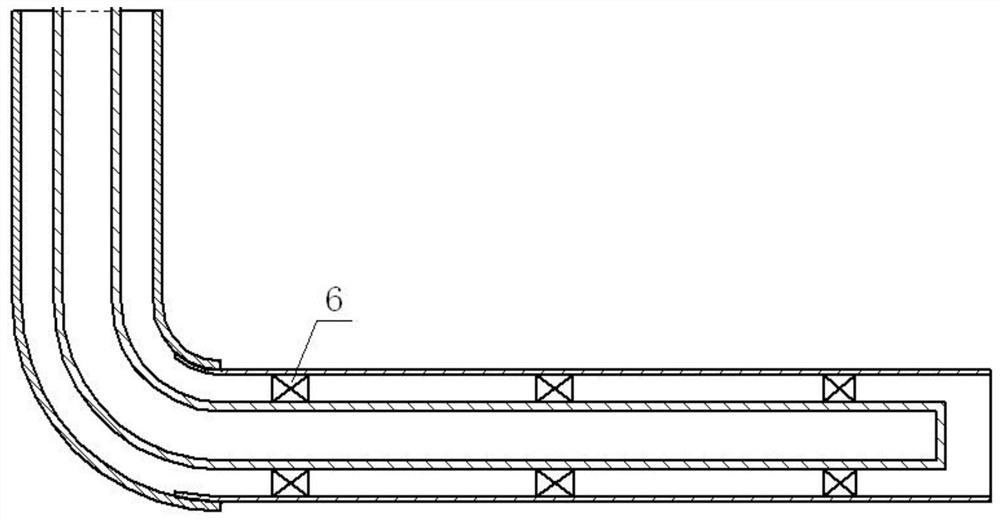

[0030] Such as Figure 3-5 As shown, a fracturing method combined with external packing and coiled tubing comprises the following steps:

[0031] 1) Running multiple packers 6 to isolate the exterior of the reservoir string in sections;

[0032] 2) Run the coiled tubing fracturing string inside the isolated reservoir string, and perform fracturing step by step until the fracturing is completed;

[0033] 3) Pull out the coiled tubing fracturing string;

[0034] 4) Lower the production string and complete the well.

[0035] The fracturing method provided by the invention provides the combination of external packing and coiled tubing, by running an open-hole packer with the same specification and diameter to seal the horizontal section of the reservoir, and using a coiled tubing fracturing string for sandblasting and perforating , perform fracturing step by step, and the full diameter of the wellbore after fracturing, so that after the reservoir is stimulated, the wellbore has...

Embodiment 2

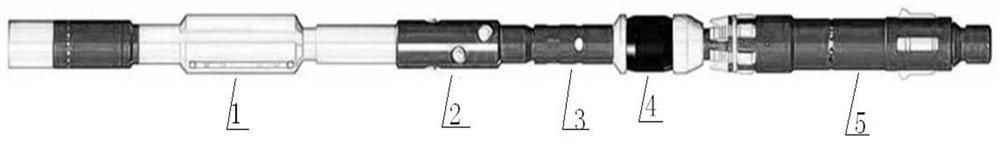

[0037] On the basis of Example 1, such as figure 1 As shown, the packer 6 is an open hole packer, and multiple open hole packers have the same diameter. The open hole packer isolates the exterior of the reservoir string in sections, and also includes a ball seat 9, a floating hoop 10, a screen 11 and a guide shoe 12, the open hole packer, the ball seat 9, the floating The hoop 10, the screen pipe 11 and the guide shoe 12 are connected in sequence. Run open hole packers of the same specification and diameter to complete the well and seal off the horizontal section of the reservoir, with uniform specifications and reduced costs; further, the open hole packers are K344, K341 and K342 three types of open hole packers for field application The sealing performance is better, and it can carry out the pretreatment construction of the formation such as large displacement forward and reverse displacement mud and well washing; the open hole packer is easy to set and unseal, and can with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com