A double-liquid grouting construction method

A construction method, double-fluid grouting technology, which is applied in the direction of earth square drilling, mining equipment, tunnels, etc., can solve the problems of uneven soil strength, high strength, and accelerated construction period, so as to achieve uniform soil mechanical strength and meet the construction requirements. The effect of security requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

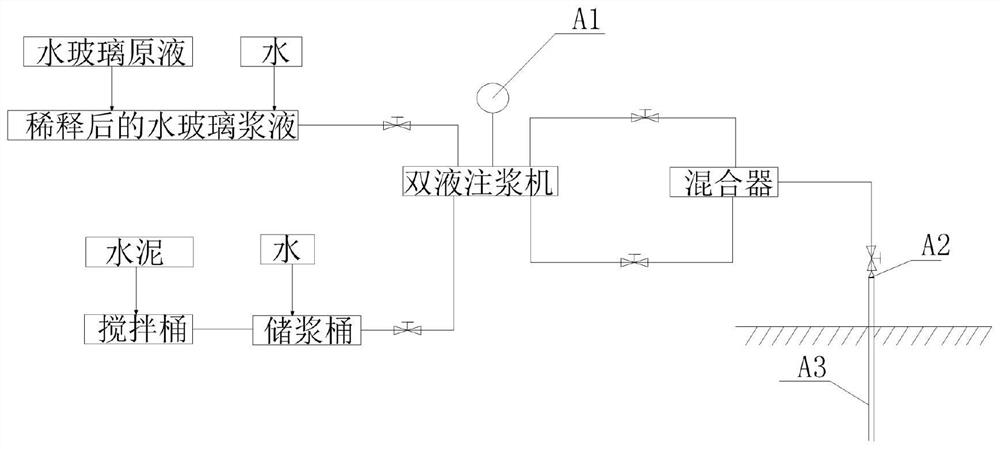

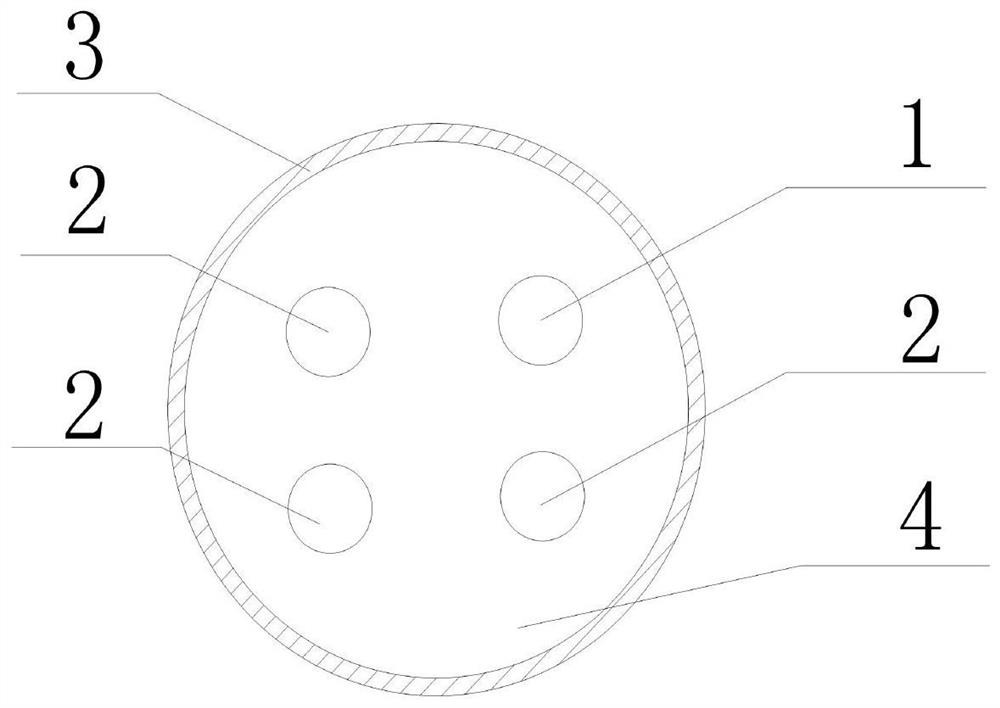

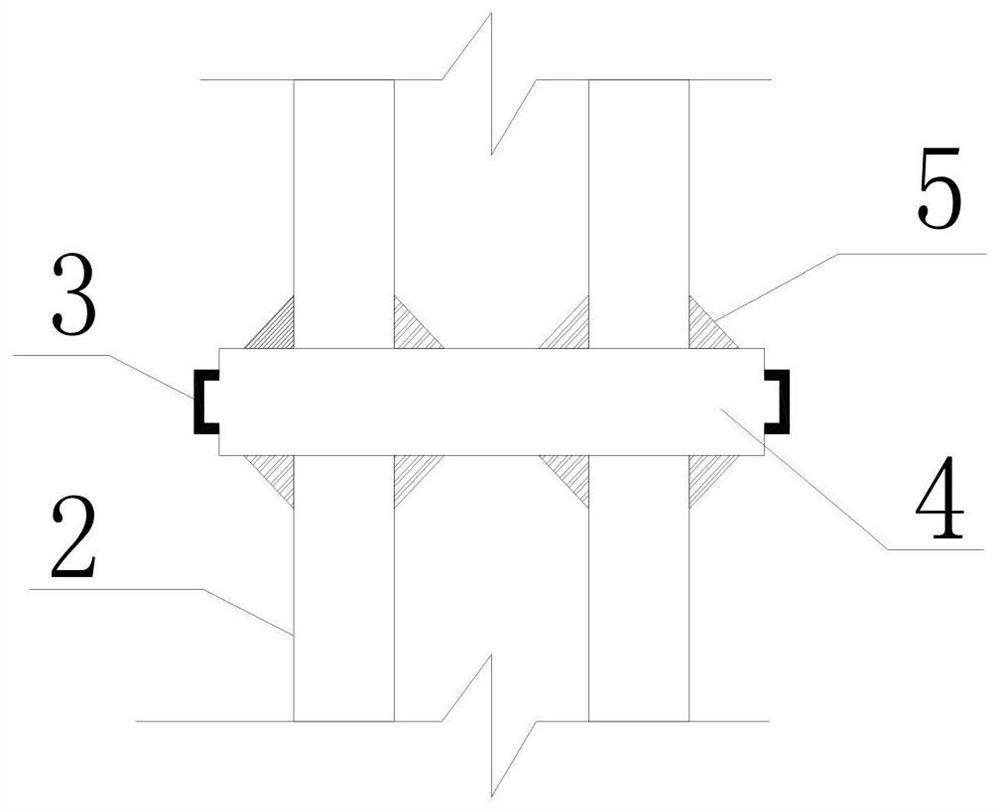

[0036] The water glass stock solution adopts 40°Bé, which is 20°Bé after being mixed with water and diluted, and the label of the cement is P.O42.5. The weight ratio of water and cement is 0.4:1. The cement and water are mixed in the mixing tank and then transferred to the slurry storage tank for temporary storage. When grouting, adjust the opening of the valve in the conveying pipe, so that the weight content of water glass is 10% of the weight of the slurry, along the direction of the second grouting pipe 2, a slurry stopper 3 is provided 6m downward from the ground. The length of the first grouting pipe 1 is 5.5m, and there are three second grouting pipes 2. The three second grouting pipes 2 and one first grouting pipe 1 form a square, and the length of the three second grouting pipes is square. They are 8m, 11m, and 14m respectively.

[0037] After mixing by the mixer, inject the slurry into the first grouting pipe 1, the grouting pressure is 0.6Mpa, adjust the mixing rat...

Embodiment 2

[0040] The water glass stock solution adopts 40°Bé, mixed with water and diluted to 25°Bé, and the label of the cement is P.O42.5. The weight ratio of water and cement is 0.6:1. The cement and water are mixed in the mixing tank and then transferred to the slurry storage tank for temporary storage. When grouting, adjust the opening of the valve in the conveying pipe so that the weight content of water glass is At 13% of the weight of the slurry, a slurry stopper 3 is provided 7m downward from the ground along the direction of the second grouting pipe 2 . The length of the first grouting pipe 1 is 6m, there are two second grouting pipes 2, the two second grouting pipes 2 and one first grouting pipe 1 form an equilateral triangle, and the length of the two second grouting pipes 13m and 17m respectively.

[0041] After mixing by the mixer, inject the slurry into the first grouting pipe 1, the grouting pressure is 1Mpa, the slurry flow rate is 25L / min, stop the injection when the ...

Embodiment 3

[0044] The water glass stock solution adopts 40°Bé, which is 30°Bé after being mixed with water and diluted, and the label of the cement is P.O42.5. The weight ratio of water and cement is 0.8:1. The cement and water are mixed in the mixing tank and then transferred to the slurry storage tank for temporary storage. When grouting, adjust the opening of the valve in the conveying pipe, so that the weight content of water glass is 17% of the weight of the slurry, along the direction of the second grouting pipe 2, a grouting stopper 3 is provided 7.5m downward from the ground. The length of the first grouting pipe 1 is 7m, and there are three second grouting pipes 2. The three second grouting pipes 2 and one first grouting pipe 1 form a square, and the lengths of the three second grouting pipes are respectively 9m, 13m, 17m.

[0045]After mixing by the mixer, inject the slurry into the first grouting pipe 1, the grouting pressure is 1Mpa, adjust the mixing ratio of the cement slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com