Negative-pressure flowback blockage removal process for oil field

A negative pressure, oilfield technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems of difficulty in popularization, high cost, and difficult evaluation of plugging removal effect, so as to avoid blowout and trip out , low safety risk points, and the effect of reducing formation leakage pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

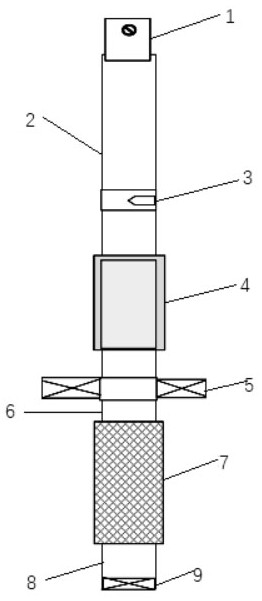

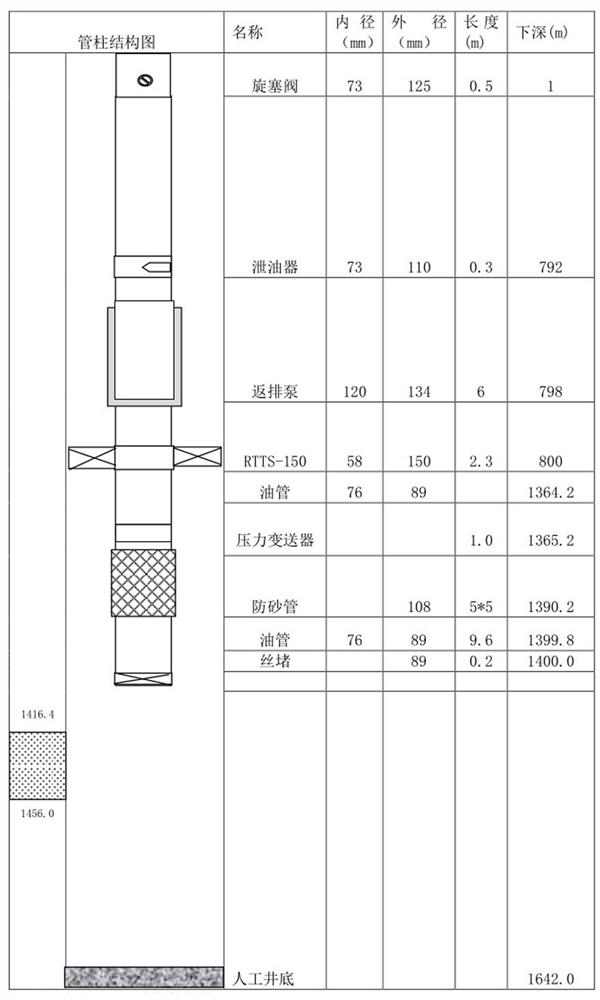

[0035] Example 1 CASH201A-20 Well Flowback Pump Negative Pressure Flowback and Blockage Removal

[0036] 1. Basic data:

[0037] .

[0038] 2. Reservoir data:

[0039] .

[0040] 3. Formation acidizing plugging removal:

[0041] Pre-connect the construction oil pipe, test the pressure of the pipeline at 25MPa, stabilize the pressure for 10 minutes, and the pressure drop is less than 0.7MPa. is qualified;

[0042] First replace 1 / 3 of the pre-treatment fluid through the oil pipe (7m 3 ) to the oil zone near the wellbore, close the casing gate; then squeeze 2 / 3 of the pre-treatment fluid (18m 3 ), the main acid plugging solution (25m 3 ) and active water post solution (25m 3), observe the wellhead pressure during the construction process, control the casing pressure within 10MPa, and remove the plugging as much as possible; close the wellhead gate, install a pressure gauge at the wellhead, shut down the well for 1-2 hours, and proceed to the next step after the press...

Embodiment 2

[0063] Example 2 Technical comparison with the existing flowback process

[0064] The flowback and blockage removal method currently adopted is the nitrogen foam flowback and blockage removal method, but its cost is relatively high, and since it is applied in new and old offshore wells, it is easily subject to the larger constraints of flowback tanker working conditions and marine weather. Compared with it, the present invention The negative pressure flowback method provided by the flowback pump has significant advantages in terms of the cost of the mobile platform, the integration of mining and repairing platform, construction equipment, and construction period, as shown in Table 2.

[0065] Table 2 Construction items and cost data

[0066] .

[0067] In addition to the significant advantages in terms of construction projects and costs, the safety and risk points of the entire project were also compared, as shown in Table 3:

[0068] Table 3 Flowback Risk Points

[0069]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com