Grouting pump for runway snow-melting composite pipe and working method of grouting pump

A technique for grouting pumps and composite pipes, which is applied in the field of grouting pumps for snow-melting composite pipes on runways, and can solve the problems of not designing grouting pumps for this purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but are not intended to limit the protection scope of the present invention.

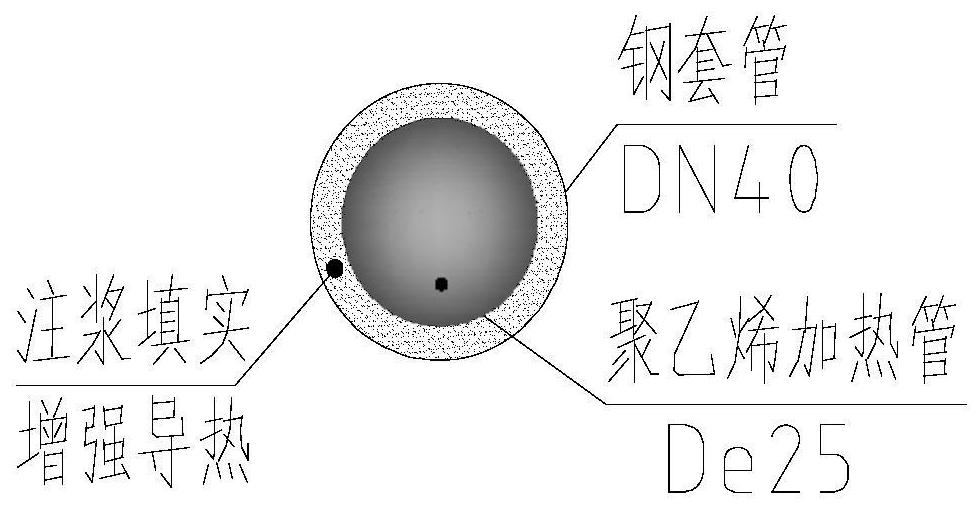

[0035] This embodiment provides a specially designed grouting pump for snow-melting composite pipes on runways.

[0036] Due to the design requirement of the pump is small flow, high head, and the fluid has the physical characteristics of high viscosity and high density, it is selected as a positive displacement reciprocating pump. Positive displacement reciprocating pumps use the periodic volume changes in the working chamber to transport fluids. They are suitable for transporting various media with small flow rates and high lifts, such as high-viscosity, corrosive, flammable and explosive liquids. Conforms to the fluid (slurry) transport characteristics.

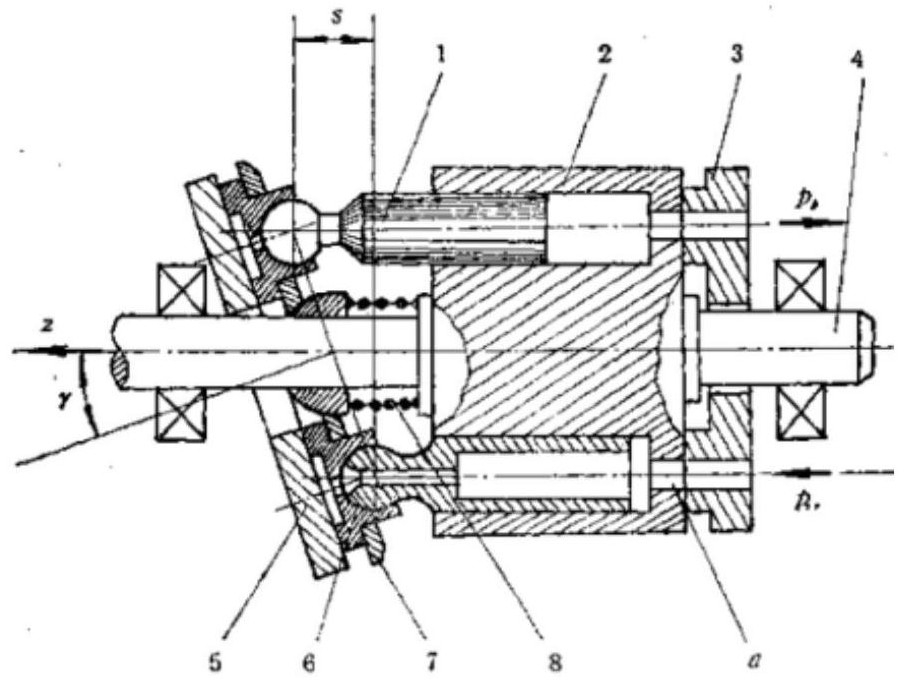

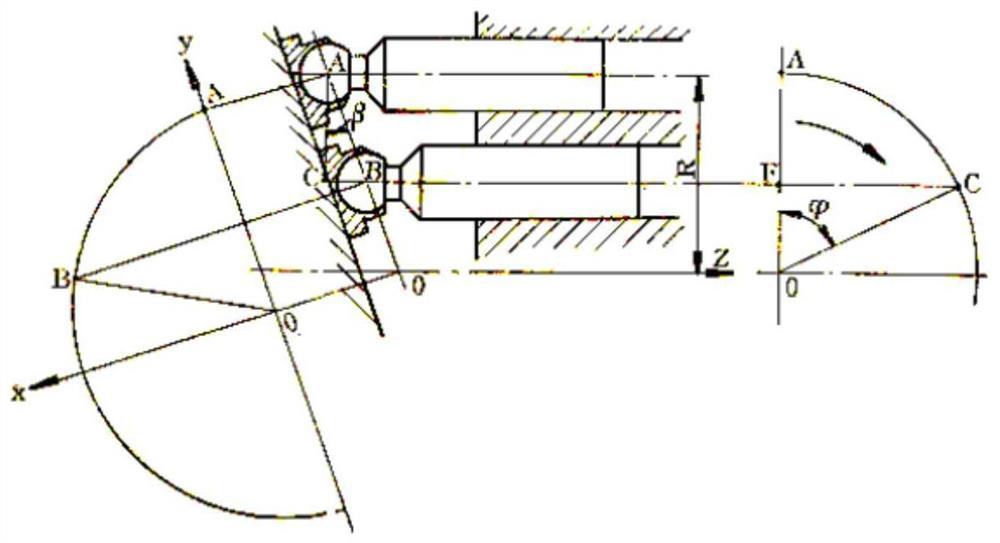

[0037] In order to adapt to the above characteristics, the axial plunger pump is selected, that is, the plunge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com