Gas-liquid mixing and conveying device with three-jaw rotor

一种输送装置、气液混合的技术,应用在用于弹性流体的泵送装置的部件、用于弹性流体旋转活塞式/摆动活塞式的泵组合、旋转活塞式/摆动活塞式的泵部件等方向,能够解决做功性能降低、流量低、发热源本体-工艺气体压缩比、周期气量考虑等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

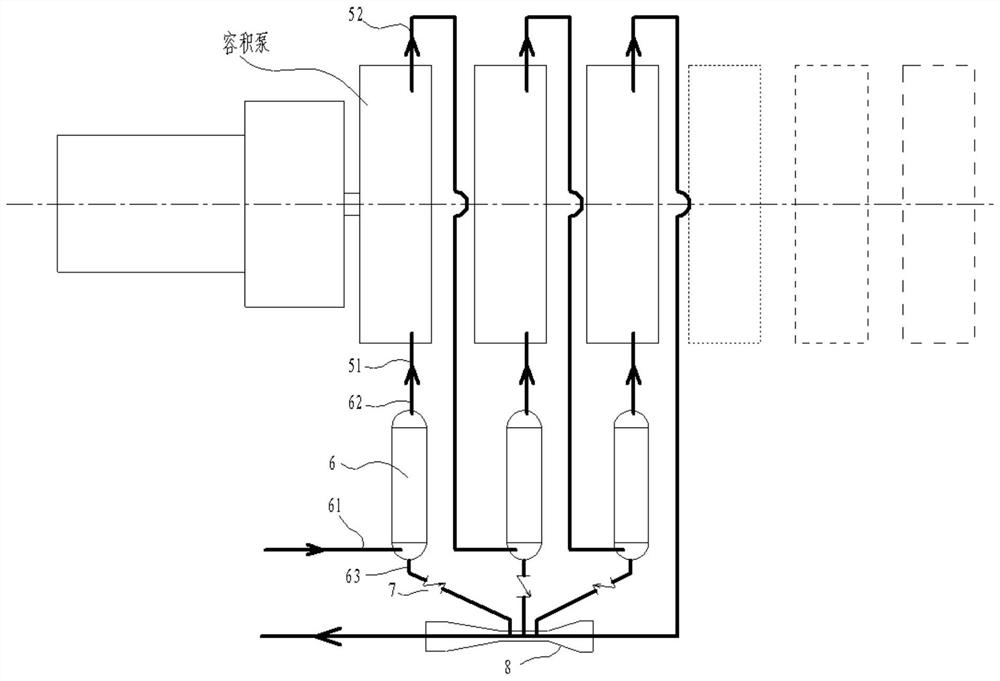

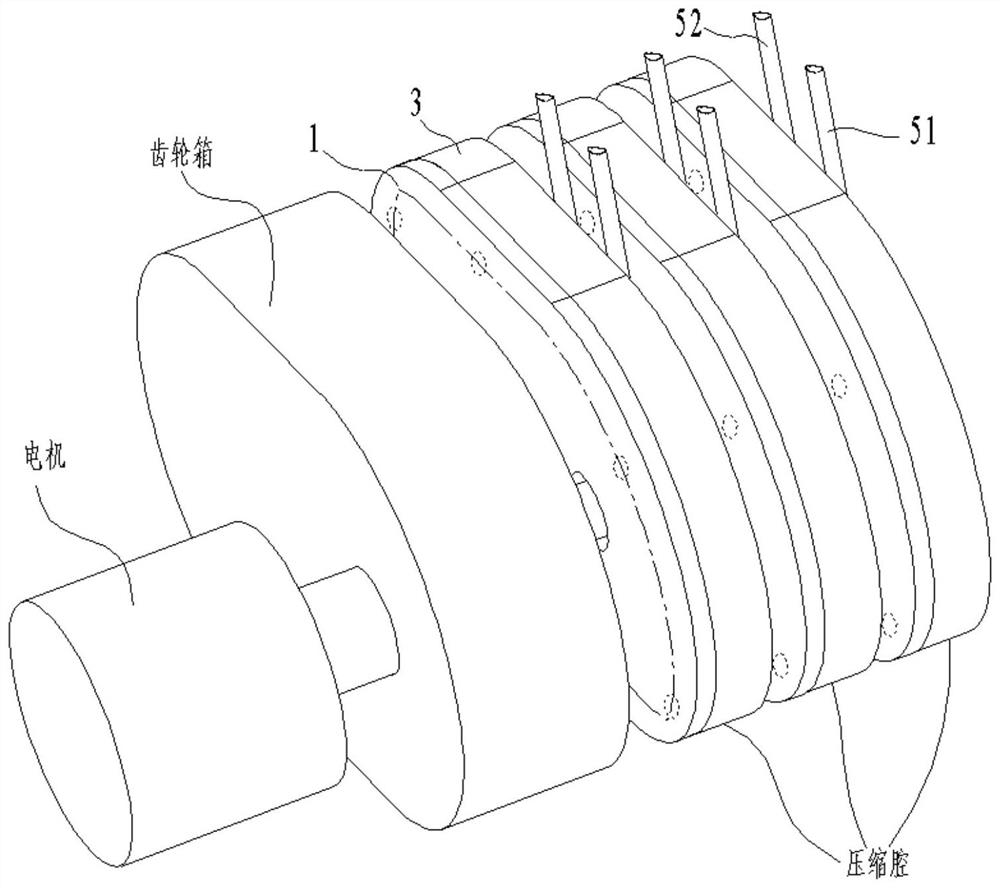

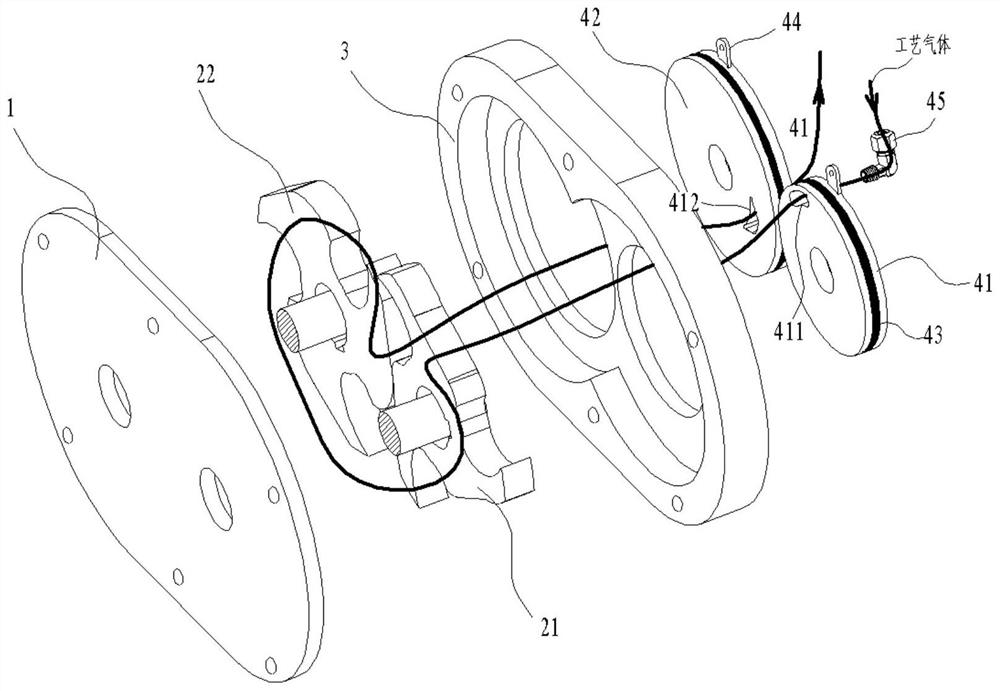

[0037] Such as figure 1 , 7 As shown, a gas-liquid mixing conveying device with a three-claw rotor includes a positive displacement pump, a heat exchanger 6 and a venturi tube 8, and the heat exchanger 6 includes an air inlet 61, an air outlet 62 and a condensate outlet 63, The air inlet 61 is the medium inlet, the air outlet 62 is connected to the inlet of the positive displacement pump, the outlet of the positive displacement pump is connected to the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com