Recycling and reuse device for fine fibers in cardboard production wastewater

A technology for fiber recycling and waste water production, which is applied in the direction of papermaking, paper machine, paper machine wet end, etc., can solve the problems of cardboard quality decline, labor cost increase, dead space, etc., and achieve fiber recycling efficiency improvement, efficiency and precision improvement, recycling The effect of accuracy guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

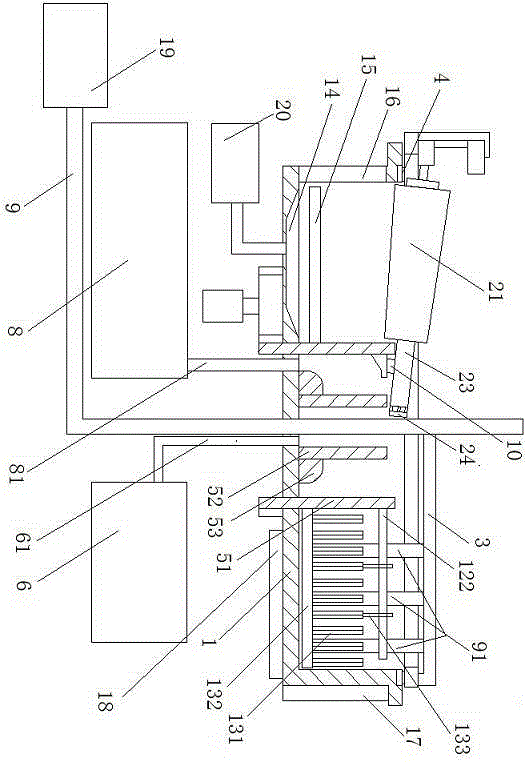

[0037] Such as figure 1 , figure 2 versus image 3 A device for recycling and reusing fine fibers in cardboard production wastewater is shown, which includes a fiber recovery tank 1 for containing wastewater generated in cardboard production, and an air compressor 11 for generating bubbles and a pressure pump 12 are connected in communication. The fiber recovery pool is provided with a fiber collection pool 6 for recovering fibers and a water purification pool 8 for recovering purified water outside the fiber recovery pool; the upper end surface of the fiber recovery pool 1 is provided with a scoop 2 which is controlled by a motor. Axial rotation. The motor for controlling the scoop 2 is arranged above the scoop, and the rotation control of the scoop 2 is achieved through the cooperation between the hinge connected with the motor main shaft and the reducer connected with the hinge.

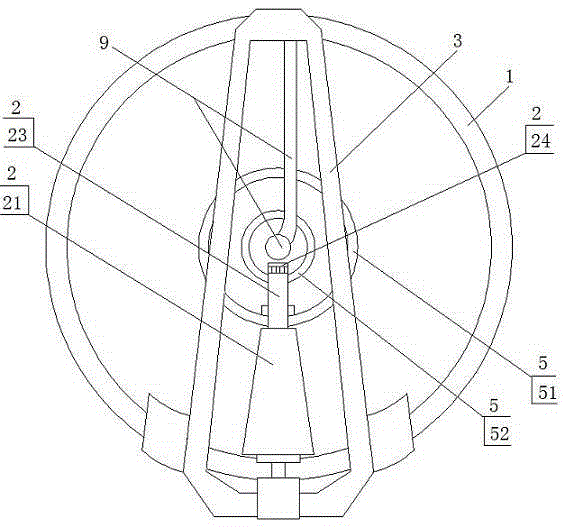

[0038] Such as Figure 4 As shown, the scoop 2 is composed of a scoop body 21 and two open ends ...

Embodiment 2

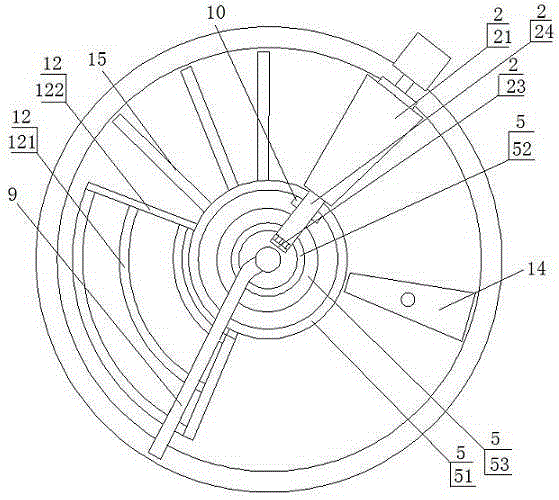

[0060] As an improvement of the present invention, such as Image 6 As shown, the upper end surface of the side wall of the fiber recovery pool 1 is provided with a chute 11, and the rotating wheel 4 is arranged inside the chute 11, wherein the driving wheel 41 is in contact with the bottom end surface of the chute 11, and its radial cross section faces the fiber recovery The interior of pool 1 is inclined. With the above design, it can prevent the rotating wheel from shifting the fiber recovery pool during the rotation process through the setting of the chute. At the same time, the inclined setting of the driving wheel can reduce the resistance in the circular rotation, making the circular motion of the support frame more efficient Stability is further improved.

[0061] The remaining features and advantages of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0063] As an improvement of the present invention, the height of the side wall of the fiber recovery tank 1 is 80 cm; in the water purification tube 5, the height of the inner wall 51 of the water purification tube is 65 cm, and the height of the central tube 52 is 60 cm; The height of the overflow weir 53 is 15 cm.

[0064] Such as Figure 7 As shown, in the central cylinder 52, the metal filter screen 7 adopts an annular structure extending along its side wall, the bottom end surface of the central cylinder 52 adopts a downwardly extending truncated cone structure, and the fiber recovery pipe 61 is provided on the bottom end surface thereof; The water outlet port is located above the side wall in the frustum-shaped bottom end surface of the central cylinder 52, and extends along the side end surface of the frustum; the central cylinder 52 is provided with a cleaning device for washing the metal filter screen 7 The device is composed of a water pump and a cleaning nozzle extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com