Powered teaching rocket launcher

A launcher and rocket technology, which is applied to rocket launchers, offensive equipment, weapon types, etc., can solve problems such as installation hazards, high mass, and high engine cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

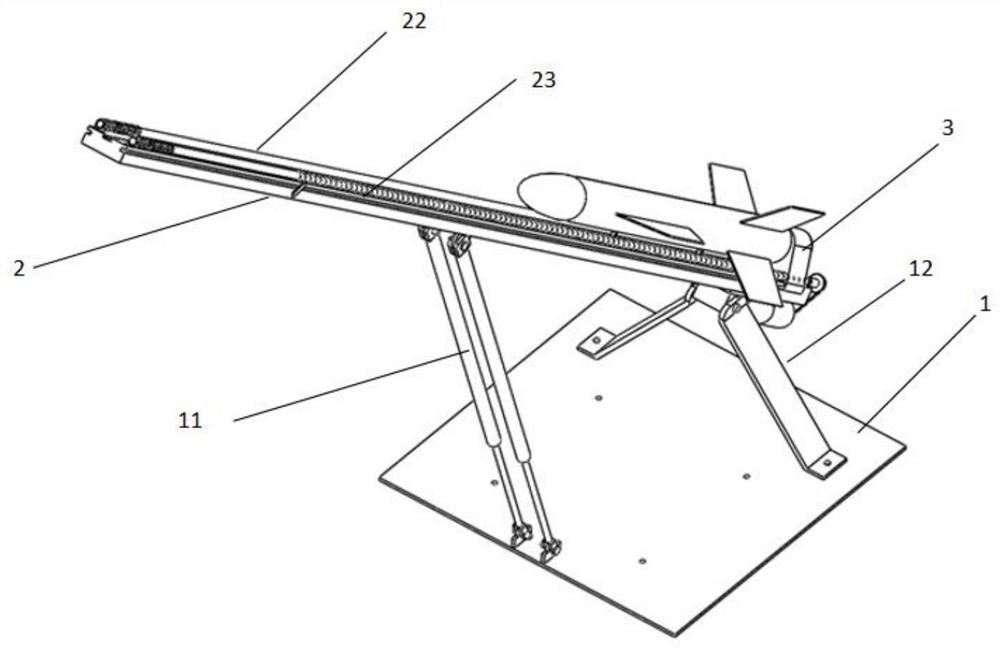

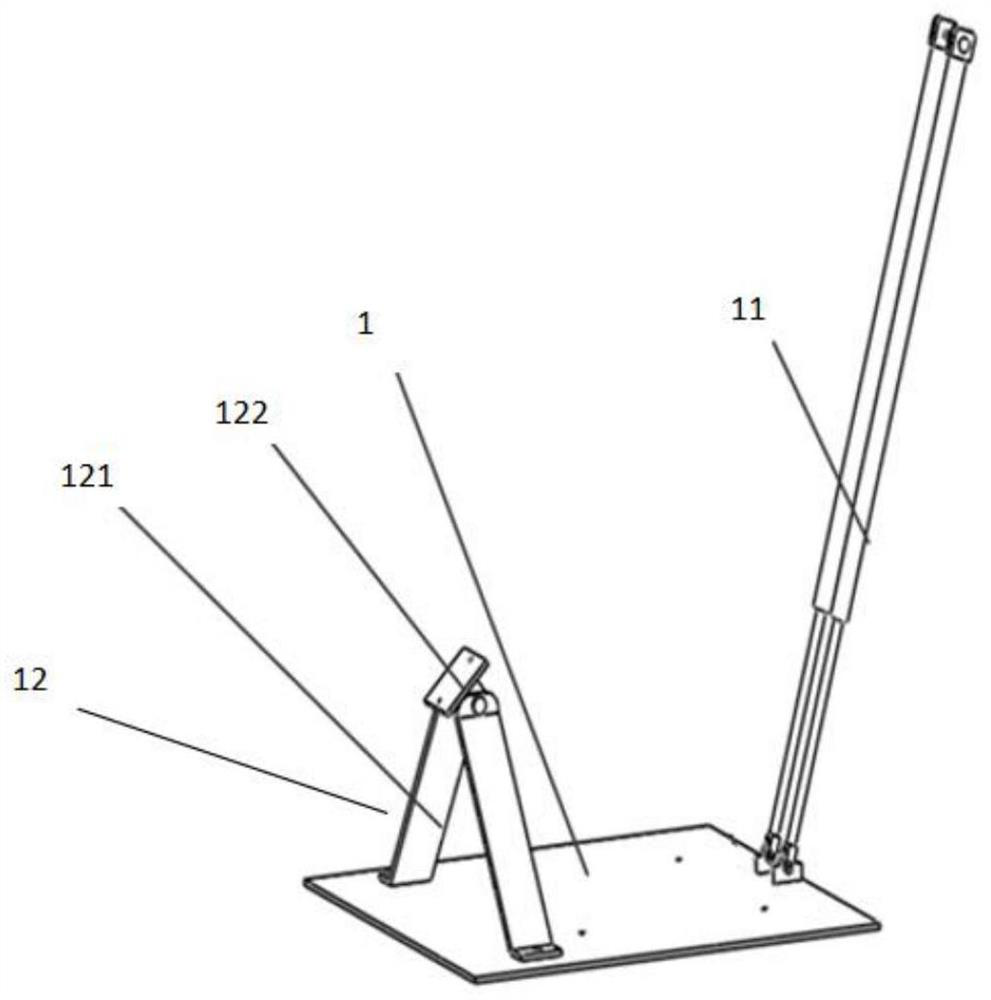

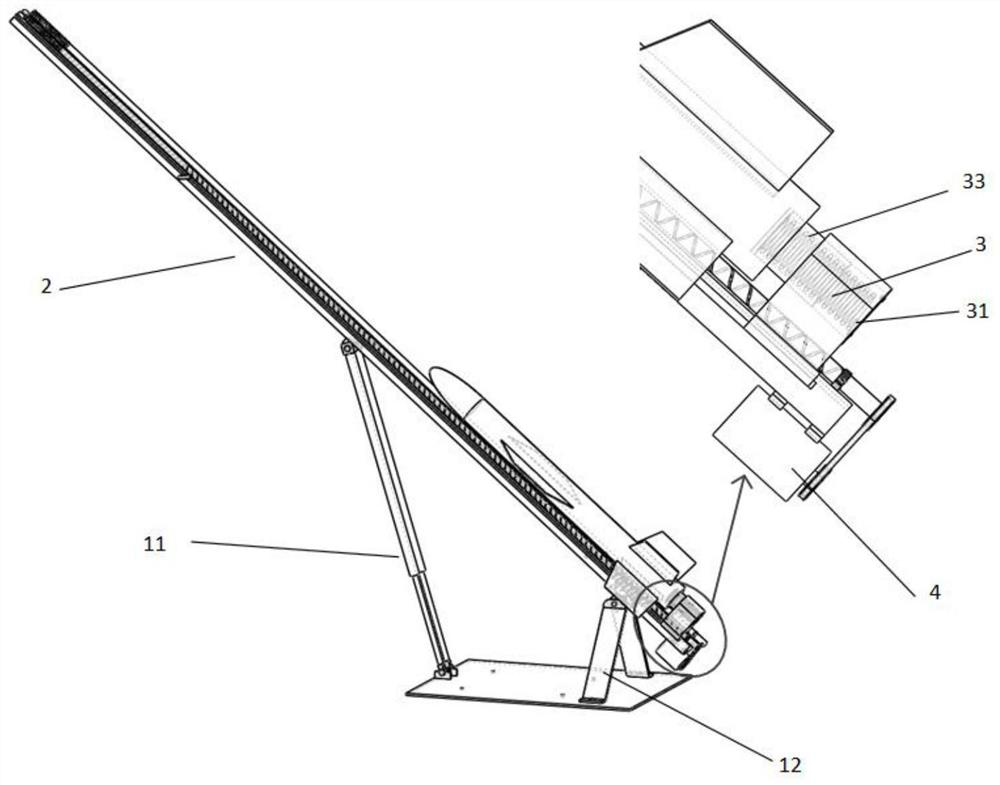

[0028] Figure 1 to Figure 8 A specific embodiment of a powered teaching rocket launcher of the present invention is shown, as figure 1 , figure 2 , image 3 , Figure 7 As shown, the launcher base 1 is included, the front and rear ends of the launcher base 1 are respectively equipped with a pitch angle adjustment support rod 11 and a guide rail slide bracket 12, and the guide rail slide table 2 is erected on the pitch angle adjustment support rod 11 and the guide rail slide bracket 12, the guide rail slide 2 is provided with a rocket sliding groove 21 for the rocket to move forward along the central axis, and a launch booster for pushing the rocket forward is installed at the tail end of the guide rail slide 2 3. In this embodiment, the launch angle of the guide rail slide table 3 is adjusted by the pitch angle adjustment support rod 11, the guide rail required for rocket launch is provided by the guide rail slide table 2, and the rocket is boosted to the launch speed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com