Product input power supply switching product non-power-down automatic test system and method

A technology of automated testing and power input, which is applied in general control systems, control/regulation systems, and measurement electronics. It can solve the problems of inability to realize automated process testing, low testing efficiency, and lack of testing, so as to shorten the testing cycle and save manpower. The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

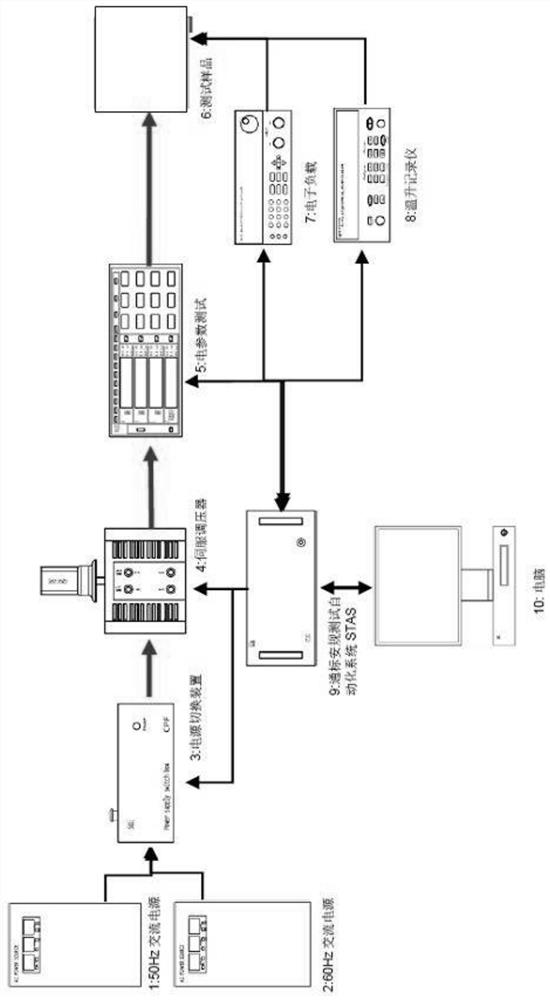

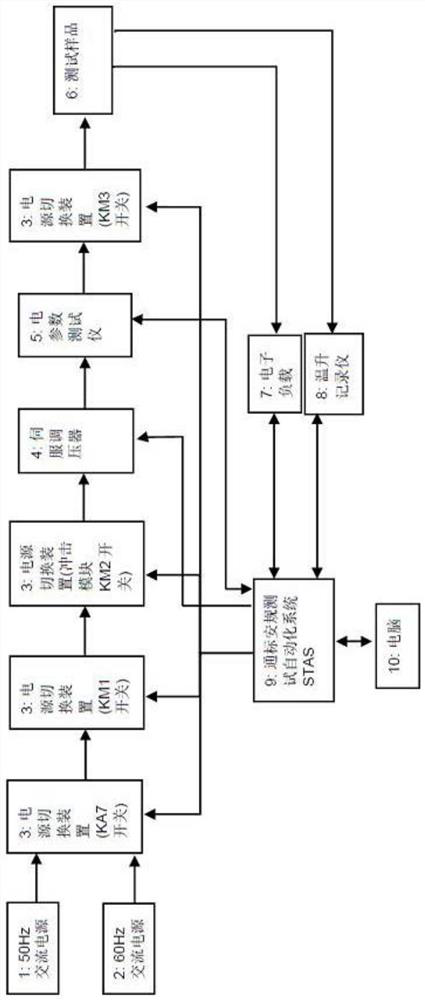

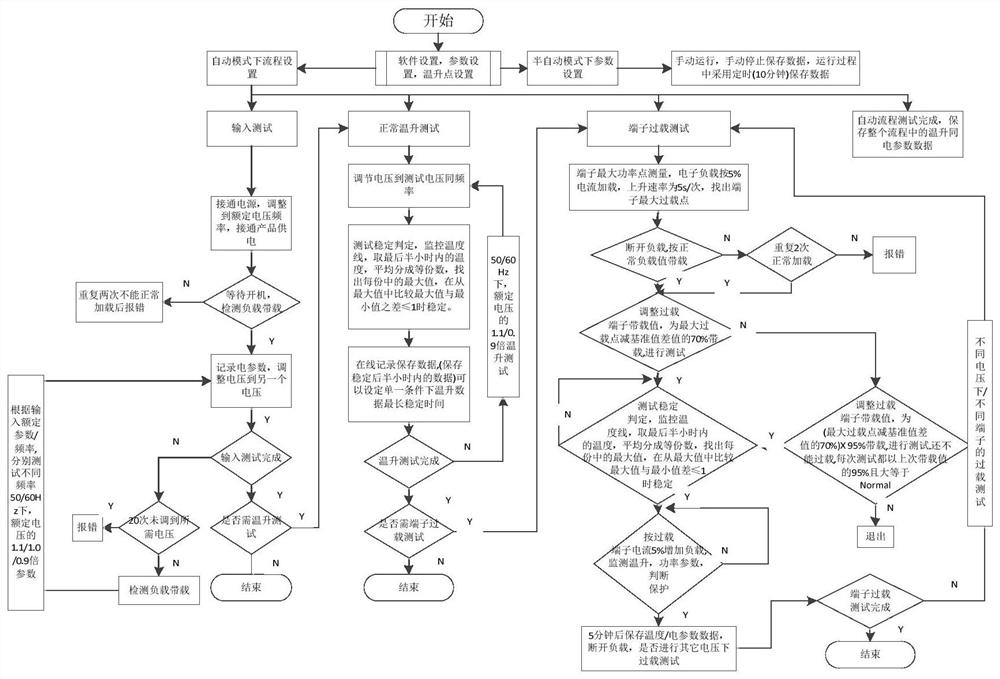

[0041] As shown in the accompanying drawings, the present invention provides an automatic test system for product input power switching without power failure, including a 50Hz AC power supply 1, a 60Hz AC power supply 2, a power switching device 3, a servo voltage regulator 4, and an electrical parameter tester 5. Electronic load 7, temperature rise recorder 8, computer 10, 50Hz AC power supply 1 and 60Hz AC power supply 2 are arranged in parallel, and the power output terminals of 50Hz AC power supply 1 and 60Hz AC power supply 2 are respectively connected to the power switching device 3, the power switching device The output terminal of 3 is connected to the input terminal of the servo voltage regulator 4, the output terminal of the servo voltage regulator 4 is connected to the electrical parameter tester 5, and the power switching device 3, the servo voltage regulator 4, and the electrical parameter tester 5 are respectively connected to the computer through lines 10. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com