Heat dissipation device capable of adaptively controlling air volume and control method thereof

A technology of self-adaptive control and heat dissipation device, which is applied to instruments, electrical digital data processing, digital data processing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

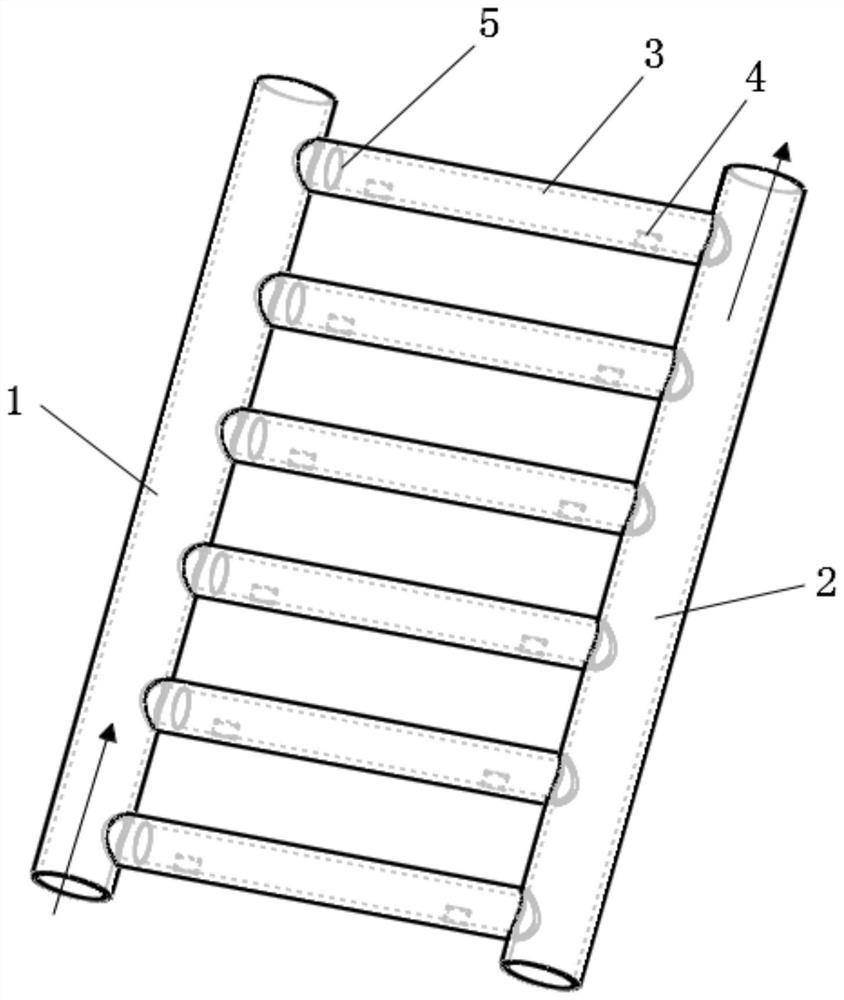

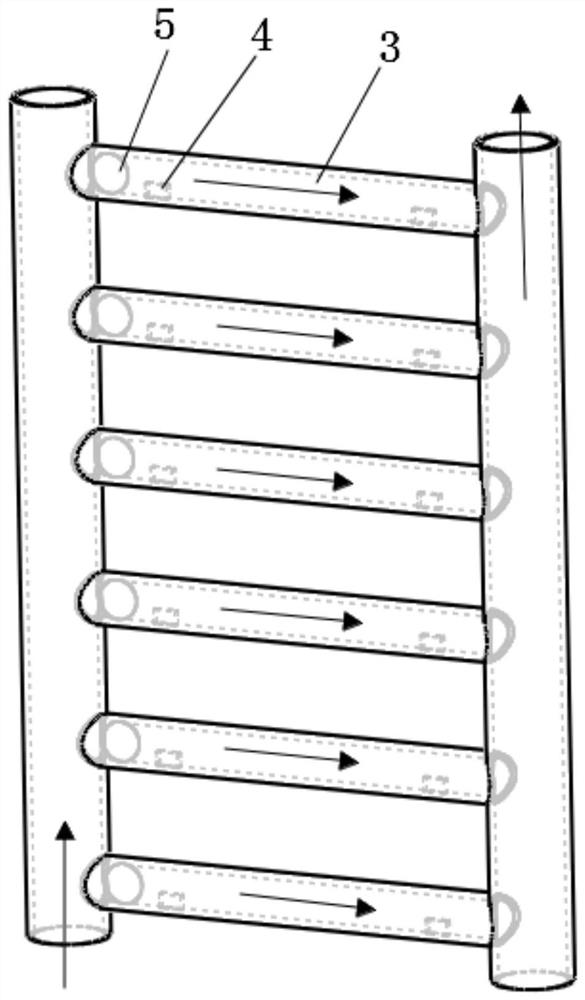

[0037] Such as figure 1 with figure 2 As shown, the present invention provides a cooling device for self-adaptive control of air volume, which mainly includes several branch air ducts 3 integrally arranged with the cabinet, and a total air inlet pipe 1 and a total air outlet pipe 2 installed on the cabinet. One end of the air duct pipe 3 is connected with the main air inlet pipe 1, the other end of the branch air duct pipe 3 is connected with the main air outlet pipe 2, and several branch air duct pipes 3 are connected between the main air inlet pipe 1 and the main air outlet pipe 2. Arranged at intervals, the air inlet of the main air inlet pipe 1 is connected to the cold air supply device, the air outlet of the main air outlet pipe 2 is connected to the hot air extraction device, and the temperature sensor 4 is installed at the air outlet of the branch air duct pipe 3. The air inlet of the duct pipe 3 is equipped with a temperature sensor 4 and an electric valve mechanism,...

specific Embodiment approach 2

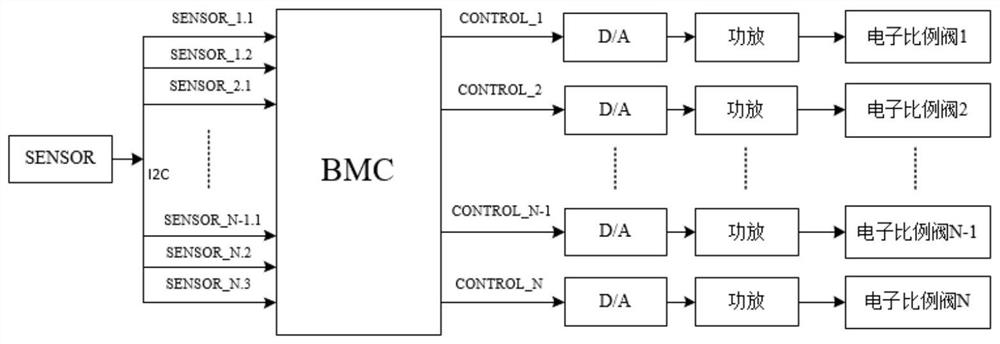

[0040] Such as image 3 with Figure 4 As shown, this specific embodiment provides a cooling device control method for adaptively controlling the air volume in specific embodiment 1, including the above-mentioned cooling device, and also includes an electric proportional regulating valve installed in the cabinet, and a temperature sensor to obtain temperature information. The calculation and processing unit for controlling air volume outputs control information to the electric proportional regulating valve, which is electrically connected to the electric valve mechanism, and the electric valve mechanism starts to act after receiving the signal transmitted by the electric proportional regulating valve, and controls the windshield blade at 0-90° Rotate within an angular range.

[0041] Further, the control method of the calculation processing unit is: set the distance between the node air inlets to be equal and be L, the number of branch air ducts is n, the first node air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com