Motor operation and maintenance method and device, electronic equipment and system

An operation and maintenance and detection technology, applied in the field of device, electronic equipment and system, motor operation and maintenance methods, can solve the problems of excessive manpower, affecting the overall efficiency of the enterprise, and excessive maintenance of equipment, so as to achieve accurate estimation and reduce data The effect of improving the transmission volume and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

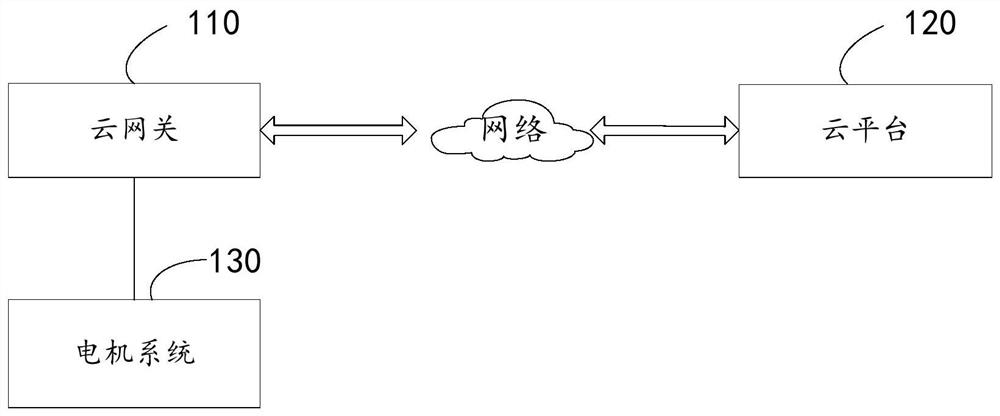

[0055] In order to facilitate the understanding of this embodiment, firstly, a motor operation and maintenance system implementing a motor operation and maintenance method disclosed in the embodiment of the present application is introduced in detail.

[0056] Such as figure 1As shown, the motor operation and maintenance system in this embodiment includes: a cloud gateway 110 and a cloud platform 120 , the cloud gateway 110 is connected to the cloud platform 120 by communication, and the cloud gateway 110 is used to connect with the motor system 130 .

[0057] The motor system 130 connected to the cloud gateway 110 is used as the motor to be detected.

[0058] The cloud gateway 110 may include an A / D conversion (analog to digital converter) module, an industrial communication module, a communication module, a storage module, an edge computing software module, and a cloud gateway ID tag.

[0059] The A / D conversion module is used to convert analog signals into digital signals....

Embodiment 2

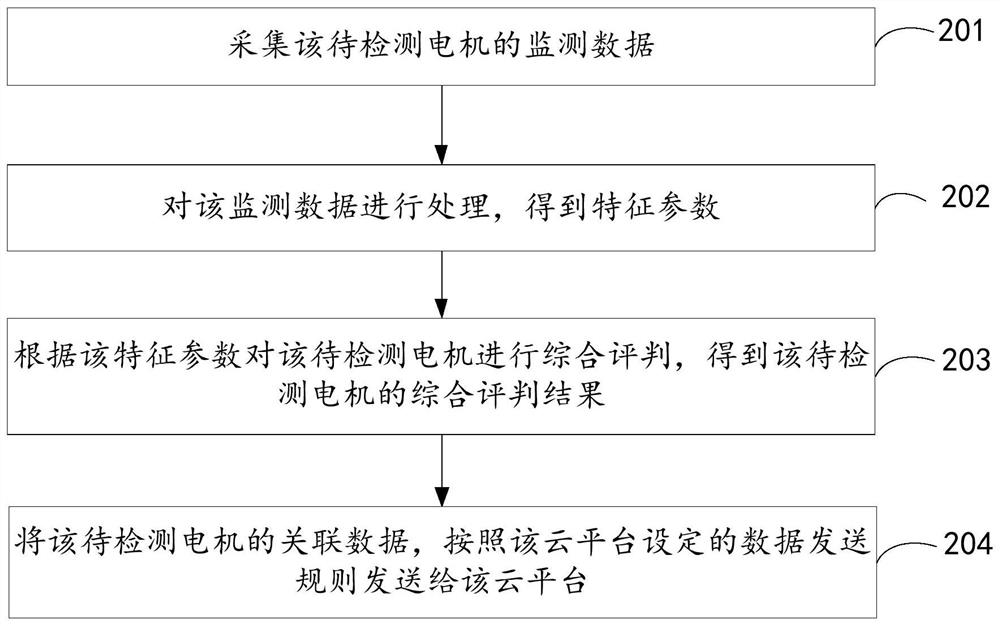

[0100] see figure 2 , is a flow chart of the motor operation and maintenance method provided in the embodiment of the present application. The motor operation and maintenance method in this embodiment can be applied to the cloud gateway; figure 2 The specific process shown will be described in detail.

[0101] Step 201, collecting monitoring data of the motor to be detected.

[0102] Step 202, process the monitoring data to obtain characteristic parameters.

[0103]Optionally, step 202 may include the following steps.

[0104] Step 2021, extract valid data in the monitoring data from the monitoring data.

[0105] For example, the monitoring data that deviates significantly from the normal value range or the normal fluctuation range or the normal fluctuation trend can be eliminated as invalid data, so as to filter out valid data in the monitoring data.

[0106] For example, the collected monitoring data may obviously deviate from the normal value range or normal fluctuat...

Embodiment 3

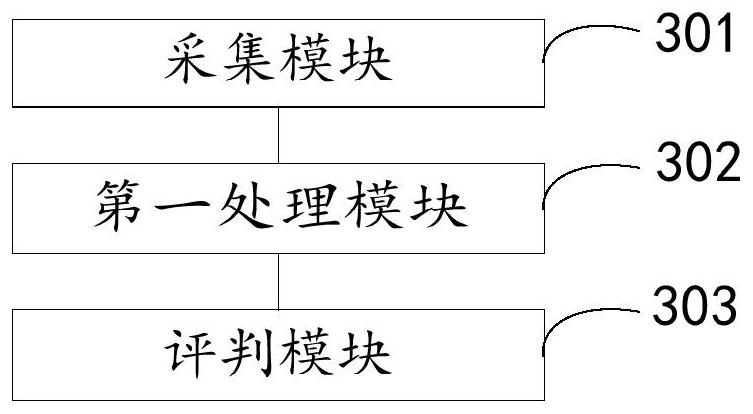

[0168] Based on the same application idea, the embodiment of this application also provides a motor operation and maintenance device corresponding to the motor operation and maintenance method. Since the problem-solving principle of the device in the embodiment of the application is similar to the aforementioned embodiment of the motor operation and maintenance method, this For the implementation of the device in the embodiment, reference may be made to the description in the embodiment of the above method, and repeated descriptions will not be repeated.

[0169] see image 3 , is a schematic diagram of the functional modules of the motor operation and maintenance device provided in the embodiment of the present application. Each module in the motor operation and maintenance device in this embodiment is used to execute each step in the above method embodiment. The motor operation and maintenance device includes: an acquisition module 301, a first processing module 302, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com