Recyclable radio frequency resonant cavity assembly as well as manufacturing process and application thereof

A resonant cavity and resonant cavity technology, applied in the field of radio frequency tags, can solve the problems of unfavorable resource reuse, increased personnel consumption, low production efficiency, etc., and achieve the effect of improving read and write sensitivity, facilitating application promotion, and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is further described below in conjunction with accompanying drawing and embodiment:

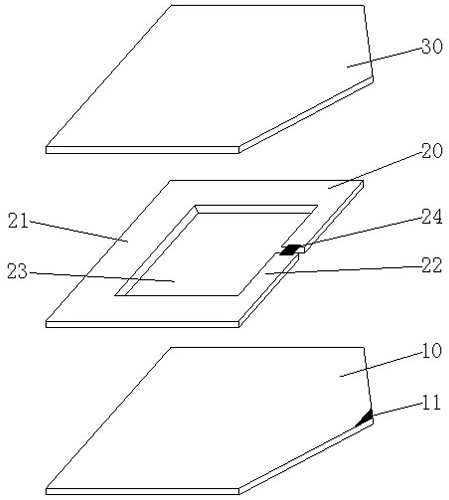

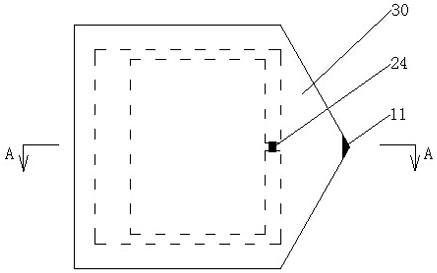

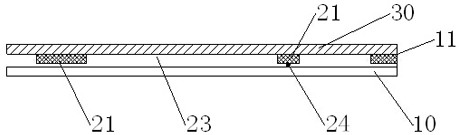

[0070] Such as Figure 1 to Figure 3 As shown, a recyclable radio frequency resonator assembly includes: a bottom PET film 10 , a resonator aluminum foil layer 20 and a top PET film 30 . Both the bottom PET film 10 and the top PET film 30 are 20-30 μm thick, which will not increase the thickness of the entire recyclable radio frequency resonant cavity assembly, and at the same time can fully realize the protective effect on the aluminum foil layer 20 of the resonant cavity.

[0071] An end point of the bottom PET film 10 is provided with a magnetic ink printing marking point 11, which facilitates the direction arrangement during label preparation and recycling. The top layer PET film 30 has the same size as the bottom layer PET film 10, and the top layer PET film 30 is fixedly connected with the bottom layer PET film 10, so that the resonant cavity aluminum foil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com