Boiled soup-stock flavored soup-stock steamed stuffed buns and preparation method thereof

A soup and flavor technology, which is applied to the preparation fields of instant food, boiled soup-flavored soup dumplings, and boiled soup-flavored soup dumplings, can solve the problems of difficulty in restoring convenient products, loss of flavor, poor eating experience when drinking soup, and the like. The effect of retaining the flavor of the broth, simple preparation process, and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

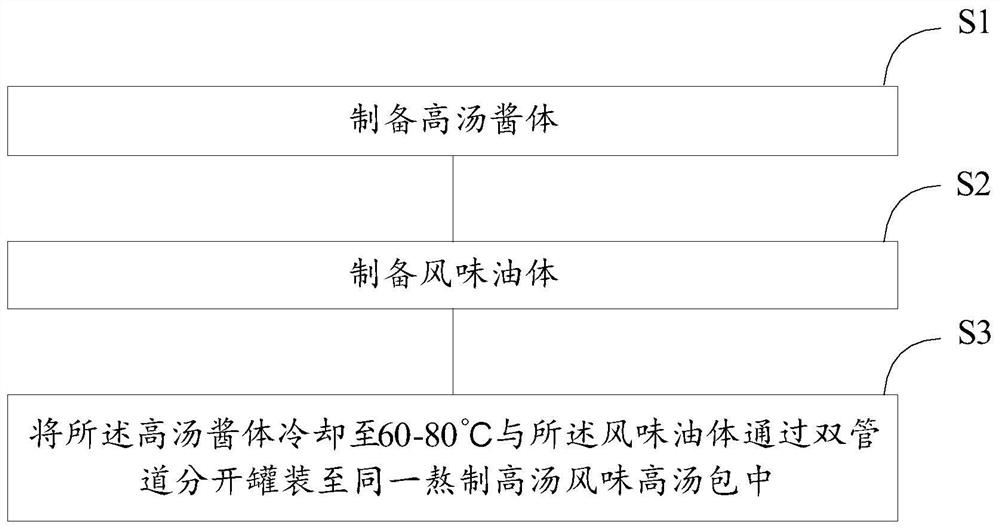

[0063] Please refer to figure 1 , figure 1 It is a process flow chart of making broth-flavored broth buns in the embodiment of the present invention. The preparation method of the boiled broth-flavored broth bag of the present invention comprises:

[0064] S1, prepare broth sauce body;

[0065] S2, preparing flavor oil body;

[0066] S3, cooling the broth sauce body to 60-80°C and canning the flavor oil body separately into the same boiled broth-flavored broth bag through double pipelines.

[0067] The boiled soup-flavored soup bag provided by the embodiment of the present invention has been improved through process and adopts double-pipeline canning technology. When the soup stock body is cooled to 60-80°C, it can be packed into the same bag separately from the flavor oil body, shortening the cooking time. The cooling time of the traditional process is shortened, and the uniformity of the oil and sauce is not considered when mixing, and the flavor of the product is preser...

Embodiment 1

[0113] Pork bone broth flavor

[0114] 1. Recipe 1

[0115] The proportion of the broth sauce body in the boiled broth-flavored broth bag is 80wt%, and 20wt% is the flavor oil body.

[0116] Broth sauce body formula: by weight, 20 parts of pork bone broth, 15 parts of water, 8 parts of pork bone seasoning sauce, 10 parts of rapeseed oil, 3 parts of salt, 5 parts of garlic, 5 parts of pork bone oil, 5 parts of chili sauce 5 parts of miso sauce, 5 parts of chicken bone broth, 2 parts of monosodium glutamate, 2 parts of sesame oil, 1 part of white sugar, 2 parts of edible alcohol, 0.5 parts of star anise, 1 part of peppercorns, and 0.5 parts of pepper.

[0117] Flavor oil formula: by weight, 80 parts of rapeseed oil, 15 parts of garlic seasoning oil, and 5 parts of sesame oil.

[0118] 2. Preparation method

[0119] (1) Heat rapeseed oil, sesame oil, and pork bone oil to 140-160°C, add garlic and fry until fragrant, and fry the garlic until golden.

[0120] (2) When the tempe...

Embodiment 2

[0127] Pork bone broth flavor

[0128] 1. Recipe 2

[0129] The proportion of the broth sauce body in the boiled broth-flavored broth bag is 90wt%, and 10wt% is the flavor oil body.

[0130] Broth sauce body formula: by weight, 30 parts of pork bone broth, 10 parts of water, 10 parts of pork bone seasoning sauce, 6.5 parts of rapeseed oil, 5 parts of salt, 3 parts of garlic, 10 parts of pork bone oil, 3 parts of chili sauce 10 servings of miso sauce, 3 servings of chicken bone broth, 3 servings of monosodium glutamate, 1 serving of sesame oil, 2 servings of white sugar, 1 serving of edible alcohol, 1 serving of star anise, 0.5 servings of pepper, and 1 serving of chili.

[0131] Flavor oil formula: by weight, 83 parts of rapeseed oil, 10 parts of garlic seasoning oil, and 7 parts of sesame oil.

[0132] The preparation method of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com