Rhombic ultrafine particle coagulation box

An ultra-fine particle, coagulation box technology, applied in the directions of dispersed particle separation, combination devices, chemical instruments and methods, etc., can solve the problems of high equipment investment and operating costs, complex process equipment, low coagulation efficiency, etc. Condensation efficiency, improve removal efficiency, reasonable partition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

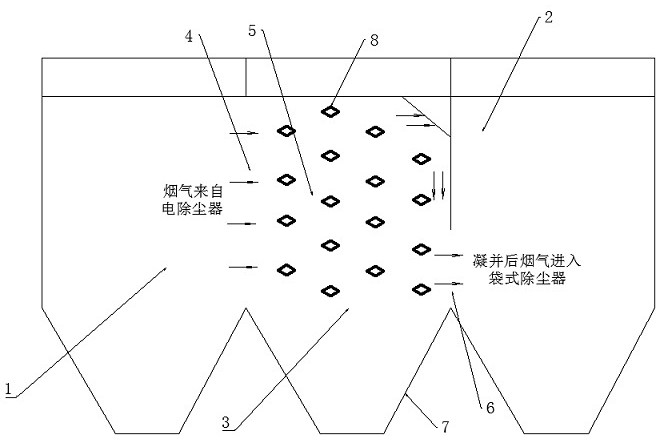

[0021] An industrial dust waste gas, the treatment capacity is 100000m 3 / h adopts the condensation box provided by the present invention. The entire condensing box is box-shaped, suitable for installation between electrostatic-bag dust collectors; the condensing box is composed of an air inlet, an air outlet, a condensing area and an ash hopper; the air inlet is the passage behind the electrostatic precipitator, The flue gas comes from the electrostatic precipitator; there are 4 sets of horizontal bars in the condensation area, and the horizontal bars are placed horizontally in the condensation area. It is set as an overflow channel, and the condensed flue gas enters the bag filter for treatment; the ash hopper is set under the condensing area, flush with other ash hoppers of the electrostatic-bag filter.

[0022] The horizontal bars set in the condensation area are arranged up and down in each group, and the diamond-shaped opening angle of the horizontal bars is 60 degrees;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com