Heating device

A heating device and resistance heating technology, which is applied in the fields of electrography, optics, current collectors, etc., can solve the problems of inability to provide voltage for resistance heating elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0055] (first embodiment)

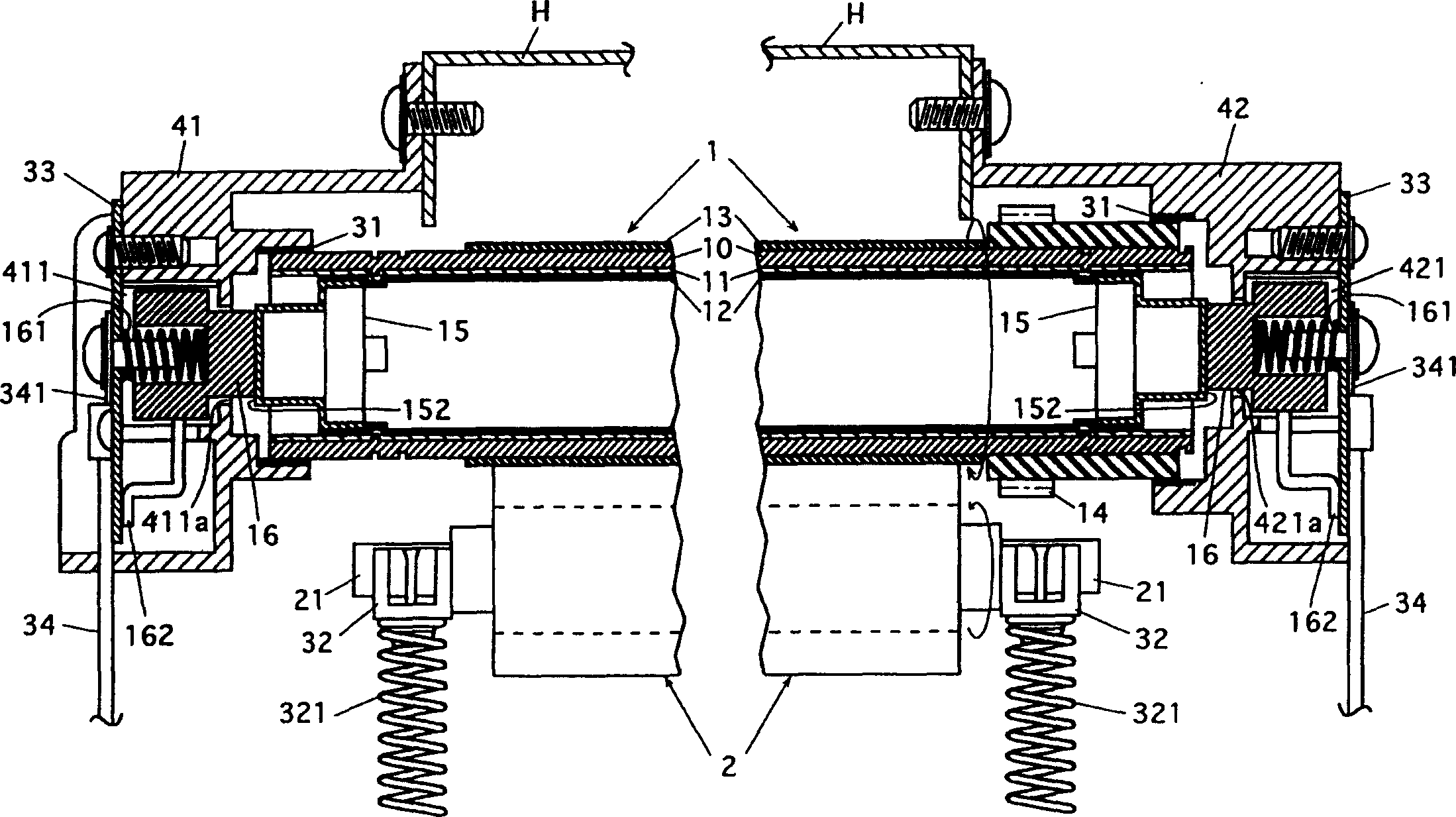

[0056] figure 1 It is a sectional view of a heating roller device (heating device) of the present invention. especially, figure 1 is a sectional view of a fixing device equipped with a heat roller unit. This fixing device is installed in an electrophotographic imaging device such as a copying machine, a printer or a facsimile machine, and can be used to fix an unfixed toner image on a record or an unfixed toner image by applying heat and pressure thereto. On the paper of shadows.

[0057] This fixing device has a heating roller device including a heating roller 1 and a pressure roller 2 opposite to the heating roller 1 .

[0058] The heating roller 1 is rotatably mounted at opposite ends thereof by bearings 31 . The bearing 31 on the left side of the drawing is supported by a bracket 41 mounted on the housing H of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com