Polishing rust-proof device for steel structure machining

A steel structure and grinding frame technology, which is applied in the direction of grinding/polishing safety devices, metal processing equipment, cleaning methods using tools, etc., can solve problems such as looseness, unevenness, and many scratches on the surface of steel structures, and achieve rapid cleaning , protect the steel structure and avoid scratches and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

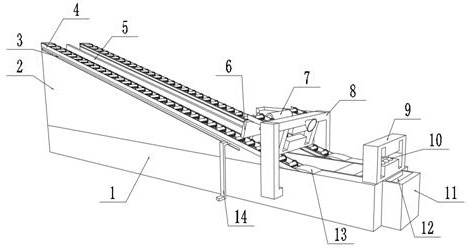

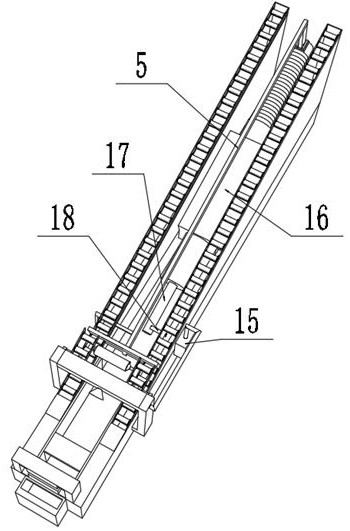

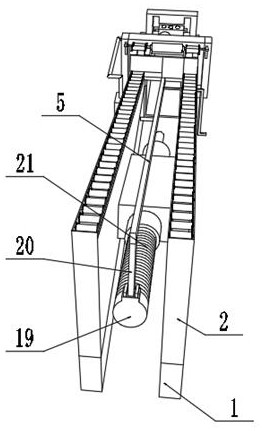

[0037] A grinding antirust device for steel structure processing, such as Figure 1-Figure 9 As shown, it includes a base 1 and a support table 2 fixed on the top of the base 1 to support and tilt upward. One side of the top of the base 1 is fixed with a pretreatment frame 9 by screws, and the side wall of the pretreatment frame 9 is opened. There is a through hole with an H-shaped structure, and the top and bottom ends of the through hole are rotatably connected with more than two groups of balls 10; the number of balls 10 is not limited. In this embodiment, preferably, the number of balls 10 is two Group, the through hole of the H-shaped structure can be polished according to the unique shape of the H-shaped steel structure, and the ball 10 can be set to roll under the friction of the H-shaped steel structure to give the H-shaped steel structure a certain vibration, so as to shake the large particles adhered to the surface Rust dust reduces the pressure of subsequent scrubbi...

Embodiment 2

[0047] A grinding antirust device for steel structure processing, such as figure 1 As shown, in order to solve the problem of convenient rust cleaning; this embodiment makes the following improvements on the basis of embodiment 1: one end of the base 1 is slidably connected with a slag collecting box 11, and the top of the slag collecting box 11 is provided with two The slag receiving port 12, the slag receiving port 12 is located under the both sides of the pretreatment frame 9, and the inside of the slag collecting box 11 penetrates the base 1 and is located directly below the fixed frame 8, so as to be able to accept rust slag; at the same time, the base 1. A buffer table 13 is welded at the connection between the top end and the lower side of the support table 2. The buffer table 13 is a smooth arc-shaped plastic structure, which can accept the inclined connection point of the steel structure and play the role of accepting the inclined inflection point of the steel structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com