Dust collector for shot blasting

A vacuum cleaner and dust collection technology, which is applied in the direction of used abrasive processing devices, abrasives, metal processing equipment, etc., can solve the problems of large size, inconvenient ash unloading, and inconvenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

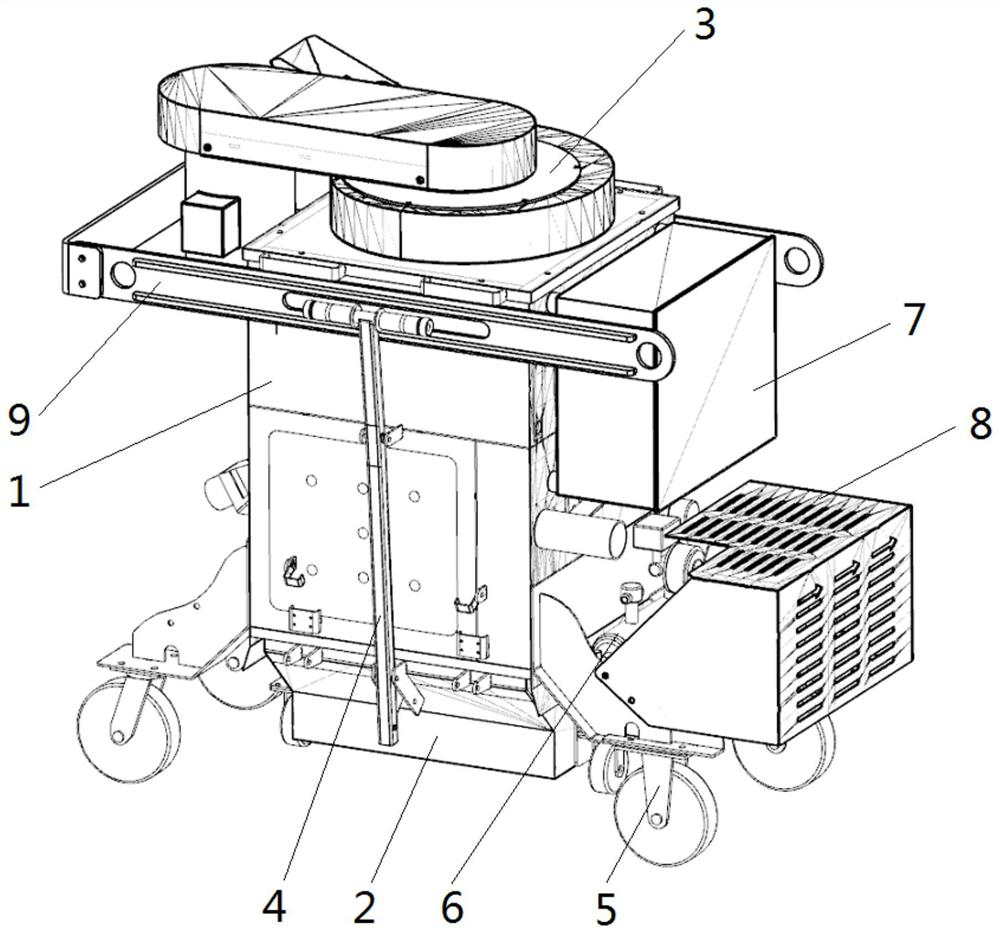

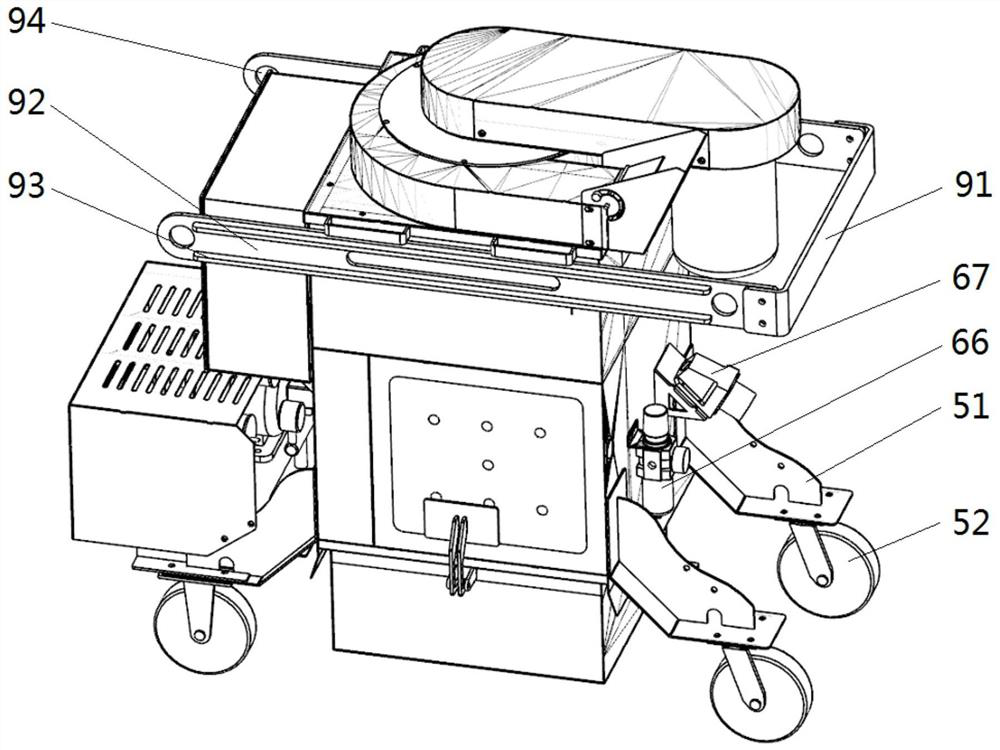

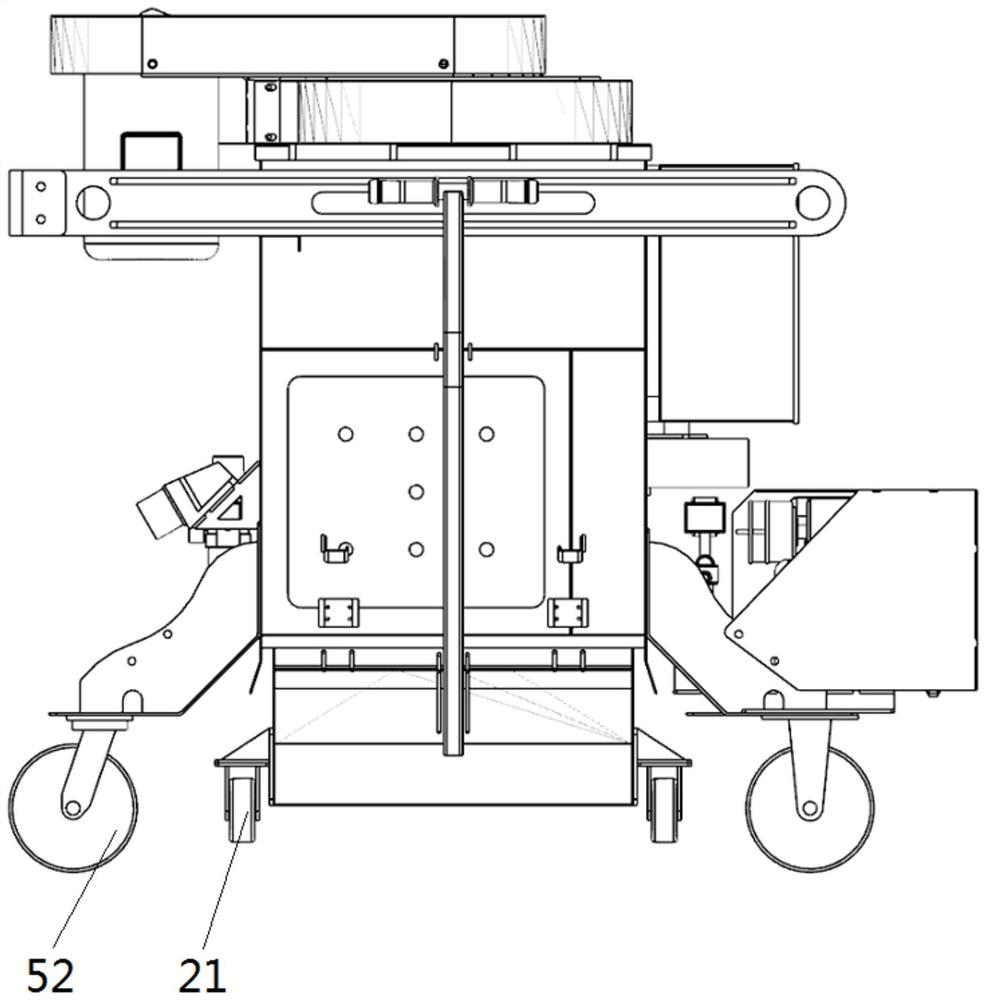

[0035] Please refer to figure 1 and Figure 5A vacuum cleaner for shot blasting provided in this embodiment mainly includes a dust removal box 1, a fan assembly 3, a dust collection box 2 and a running mechanism 5, and a partition plate 11 is arranged in the dust removal box 1, and the partition plate 11 will The inner cavity of the dust removal box 1 is divided into a dust collecting space and a dust filtering space. The dust collecting space is mainly used for processing dust and settling, and the dust filtering space is mainly used for providing a suction channel for pure air. The position can be one left one right or one up and one down, or it can be arranged obliquely upward and downward. In order to achieve a better dust reduction effect and facilitate installation and positioning, the partition board 11 here is arranged horizontally , separate the dust collecting space and the dust filtering space into a form of distribution one above the other. One side of the dust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com