Assembling device for wood sword production

A technology of assembling device and wooden sword, which is applied to adhesive application devices, wood processing appliances, glue containers, etc., can solve problems such as low assembly efficiency, and achieve the effect of reducing manual operation and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

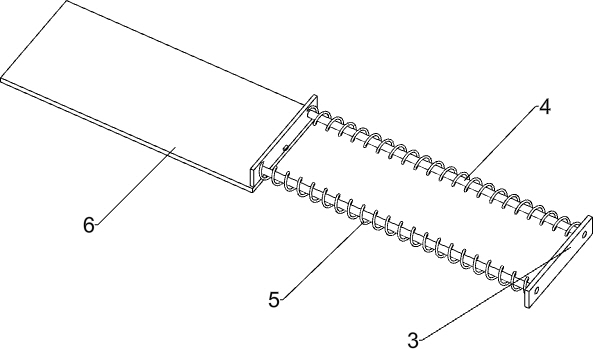

[0041] An assembly device for the production of wooden swords, such as Figure 1-2 As shown, it includes a base 1, a mounting plate 2, a square frame 3, a guide rod 4, a first elastic member 5, a placement plate 6, a transfer table 7, a slide plate 8, a discharging mechanism 9 and a pressing mechanism 10. On the base 1 A mounting plate 2 is provided, and a square frame 3 is embedded in the right side of the mounting plate 2. Guide rods 4 are provided on the front and rear sides of the right wall of the square frame 3. The left part of the guide rod 4 is slidingly connected with a placement plate 6, and the placement plate 6 The first elastic member 5 is arranged between the right wall and the right wall of the square frame 3, the first elastic member 5 is wound on the guide rod 4, the left side of the top of the mounting plate 2 is provided with a transmission platform 7, and the right side of the transmission platform 7 is provided with a Sliding plate 8, sliding plate 8 is i...

Embodiment 2

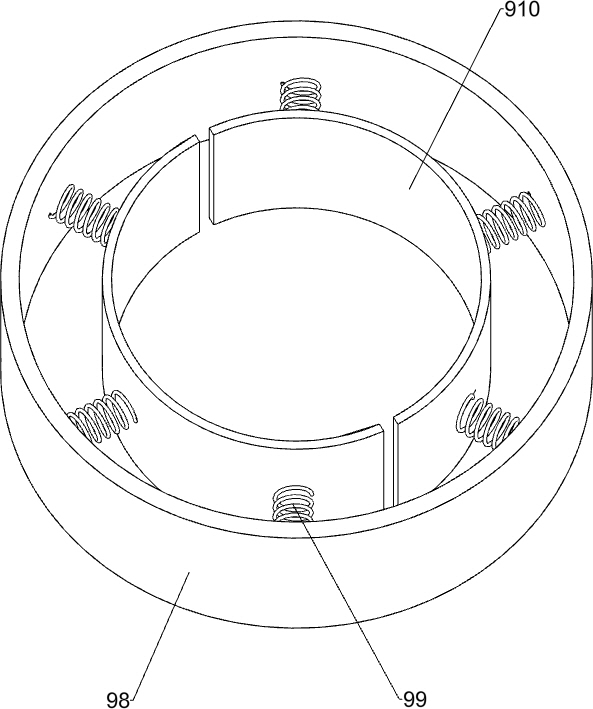

[0044] Specifically, such as Figure 3-5 As shown, the discharge mechanism 9 includes a cylinder 91, a first rotating shaft 92, a circular plate 93, a guide post 95, a disk 96, a second elastic member 97, a ring frame 98, a third elastic member 99 and a semicircle clamping block 910, Mounting plate 2 right side rear parts are provided with cylinder 91, and cylinder 91 interior rotation type is equipped with first rotating shaft 92, and first rotating shaft 92 middle part and top are all provided with circular plate 93, evenly opened on the circular plate 93 above is provided with six A circular groove 94, a circular shape is evenly connected with a guide post 95 between the circular plates 93 on the upper and lower sides, and a disc 96 is installed on the top of the guide post 95, and the disc 96 slides and is located in the circular groove 94. A second elastic member 97 is evenly arranged between the bottom of the 96 and the circular plate 93 below, and the second elastic mem...

Embodiment 3

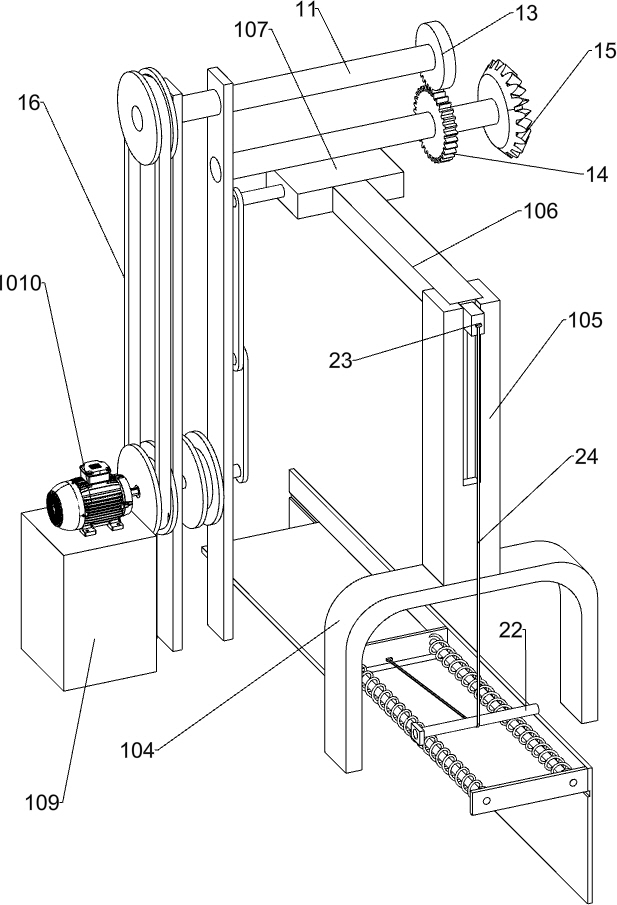

[0049] refer to Figure 6-7 As shown, it also includes a first rotating shaft 11, a second rotating shaft 12, a missing gear 13, a circular gear 14, a bevel gear 15, a first belt drive assembly 16 and a second belt drive assembly 17, and the upper part of the fixed plate 101 is rotatably provided with The first rotating shaft 11, the upper part of the fixed plate 101 on the rear side is rotatably equipped with the second rotating shaft 12, the second rotating shaft 12 is located below the first rotating shaft 11, the rear end of the first rotating shaft 11 is connected with a missing gear 13, the rear side of the second rotating shaft 12 A round gear 14 is provided, and the round gear 14 meshes with the missing gear 13. The number of teeth of the missing gear 13 is one-sixth of the number of teeth of the round gear 14. The rear end of the second rotating shaft 12 and the upper end of the first rotating shaft 92 are provided with bevel gears 15 , two bevel gears 15 are meshed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com