Semi-transparent panel production equipment and production process

A technology of production equipment and production process, applied in the field of semi-transparent panel production equipment and production process, can solve problems such as affecting the printing quality of semi-transparent panels, and achieve the effects of improving printing quality, printing accuracy and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

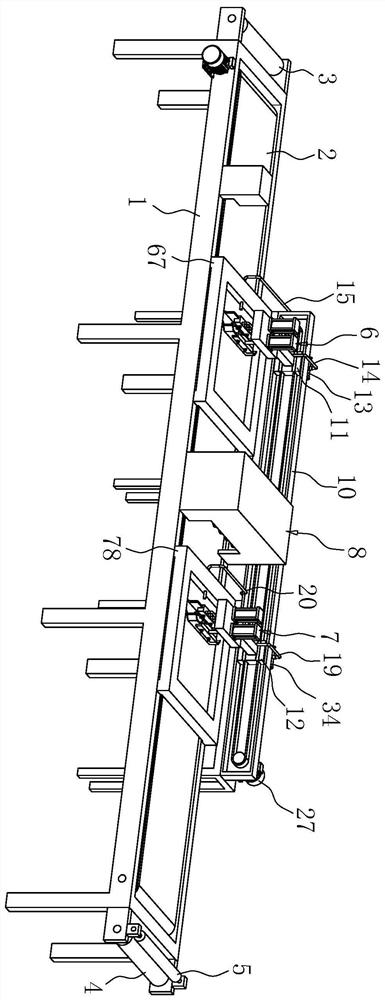

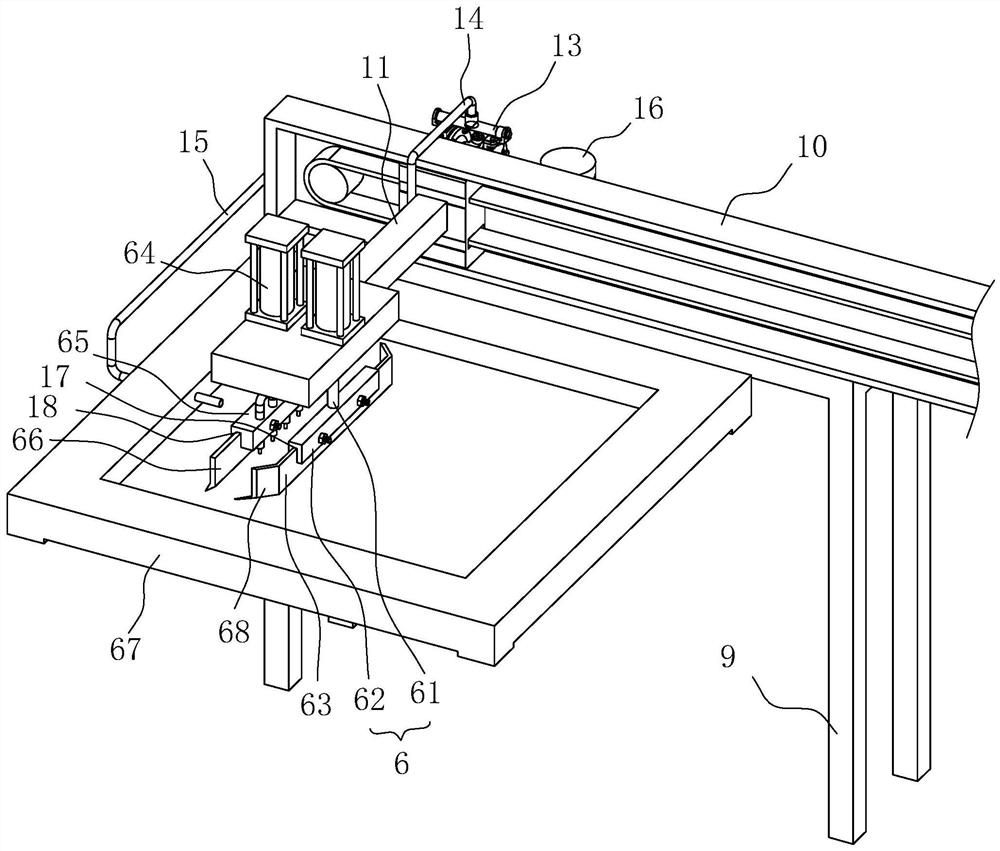

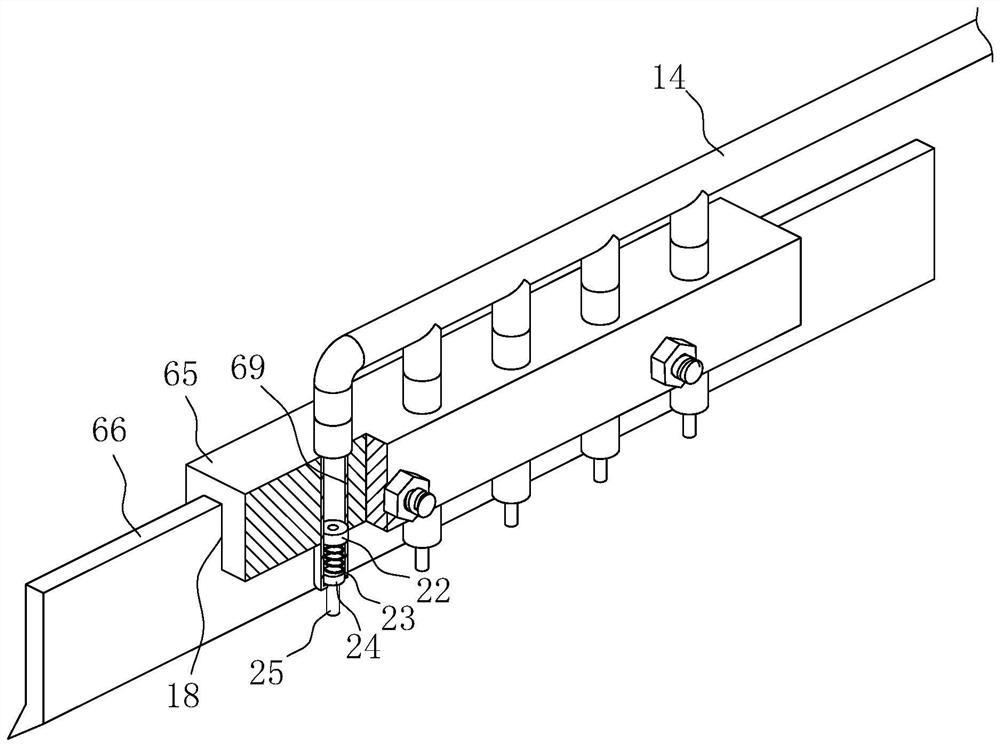

[0050] The following is attached Figure 1-6 The application is described in further detail.

[0051] The embodiment of the present application discloses a semi-transparent panel production equipment. refer to figure 1 , the semi-transparent panel production equipment includes a frame 1, a conveyor belt 2 horizontally arranged on the frame 1, and one end of the length direction of the frame 1 is rotatably connected with a feed roller 3 for conveying an unprinted semi-transparent panel, and the frame 1 One end near the feeding roller 3 is provided with a color mark sensor. The color mark sensor controls the running and stopping of the conveyor belt 2, improving the conveying accuracy of the translucent panel. The end of the frame 1 away from the feed roller 3 is rotatably connected with a conveying roller 4 for conveying the printed semi-transparent panel. The axis of the tight roller is parallel to the axis of the delivery roller 4 , and the pinch roller is arranged above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com