Floccule adsorber applied to printing and dyeing wastewater treatment

A technology for printing and dyeing wastewater and flocs, which is applied in textile industry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc. It can solve ecological environmental pollution, failure to achieve good filtering effect, and consumption of large water resources, etc. problem, to achieve the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

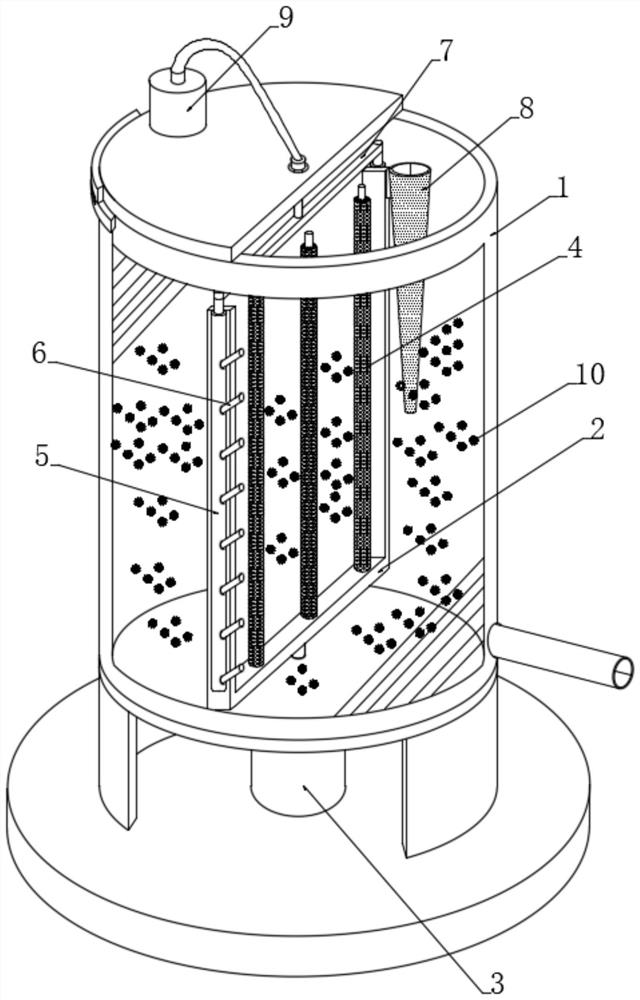

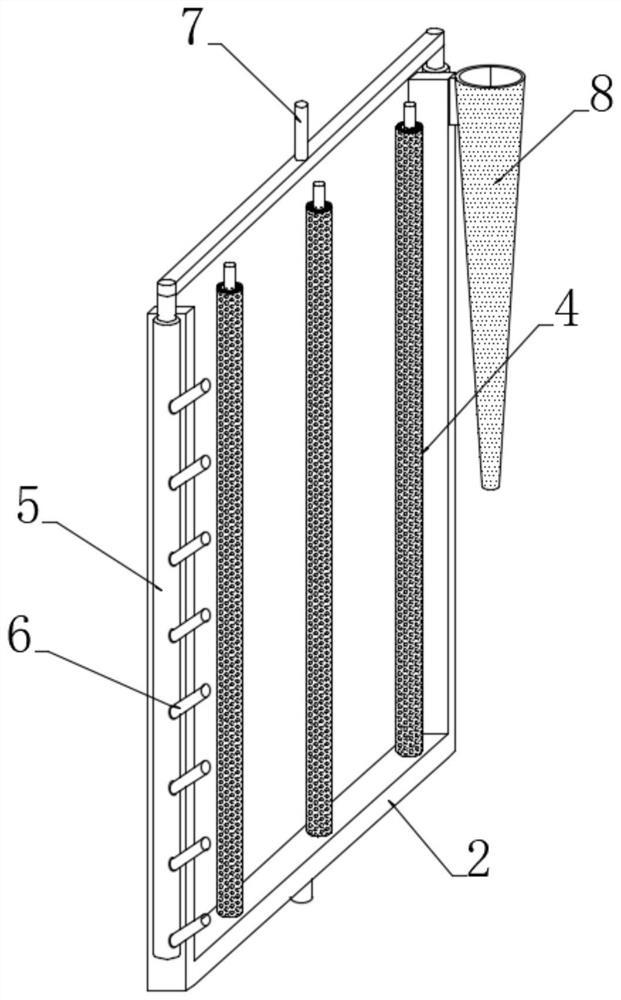

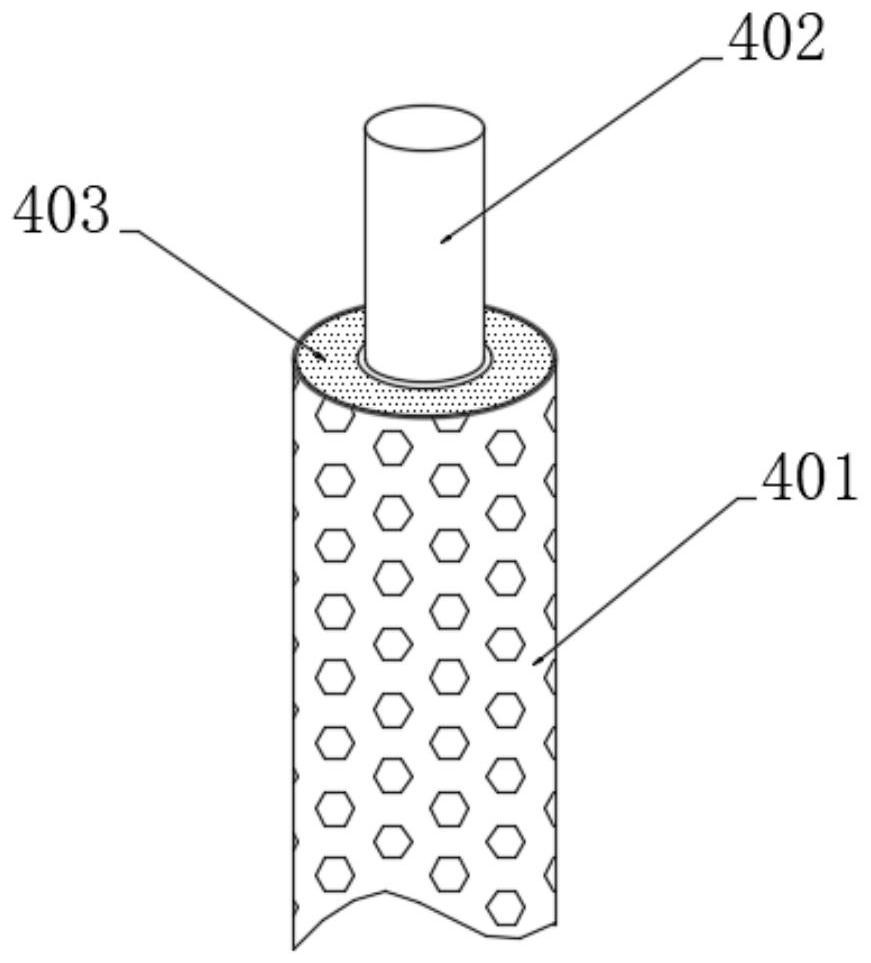

[0040] see Figure 1-3 , a floc adsorber used in printing and dyeing wastewater treatment, including an adsorption cylinder 1 with a base, a U-shaped agitation aeration frame 2 is installed on the inside of the adsorption cylinder 1, and a U-shaped agitation aeration frame is installed on the base. The rotating motor 3 driven by the frame 2, the inner bottom of the U-shaped agitation aeration frame 2 is horizontally distributed with a plurality of magnetic adsorption rods 4, and the side wall of one end of the U-shaped agitation aeration frame 2 is fixedly connected with a conical placement tube 8 , the conical placement cylinder 8 is filled with a plurality of magnetic floating suction balls 10, the bottom end of the conical placement cylinder 8 is equipped with a solenoid valve, and the magnetic floating suction balls 10 are used for adsorption treatment of floc impurities in the wastewater , the magnetic adsorption rod 4 includes a hollow ceramic adsorption carrier 401 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com