Dustproof sound-transmitting film composite part and preparation method thereof

A technology of sound-transmitting membrane and composite parts, applied in the field of membrane materials, can solve the problems of reducing the sound-transmitting effect of the dust-proof sound-transmitting membrane, low bonding strength of the dust-proof sound-transmitting membrane, affecting the development and application of MEMS, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

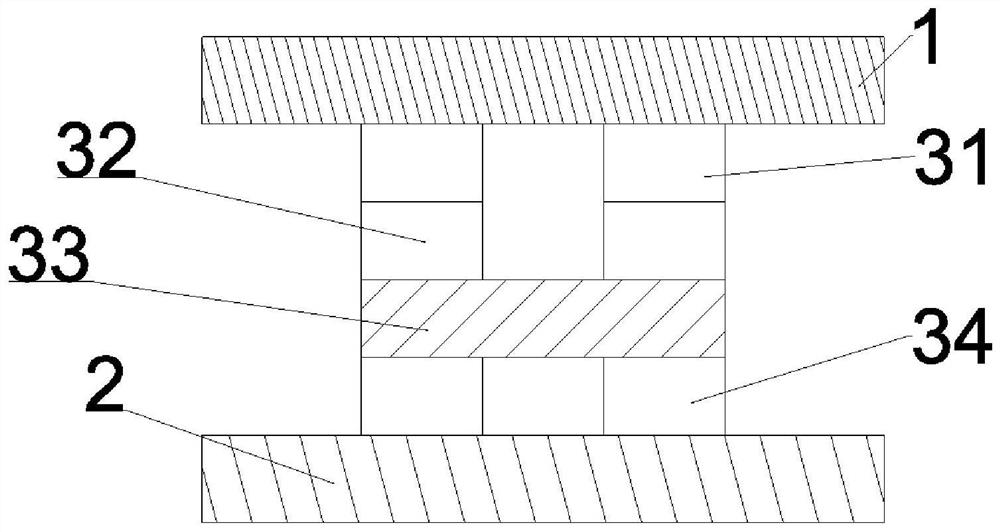

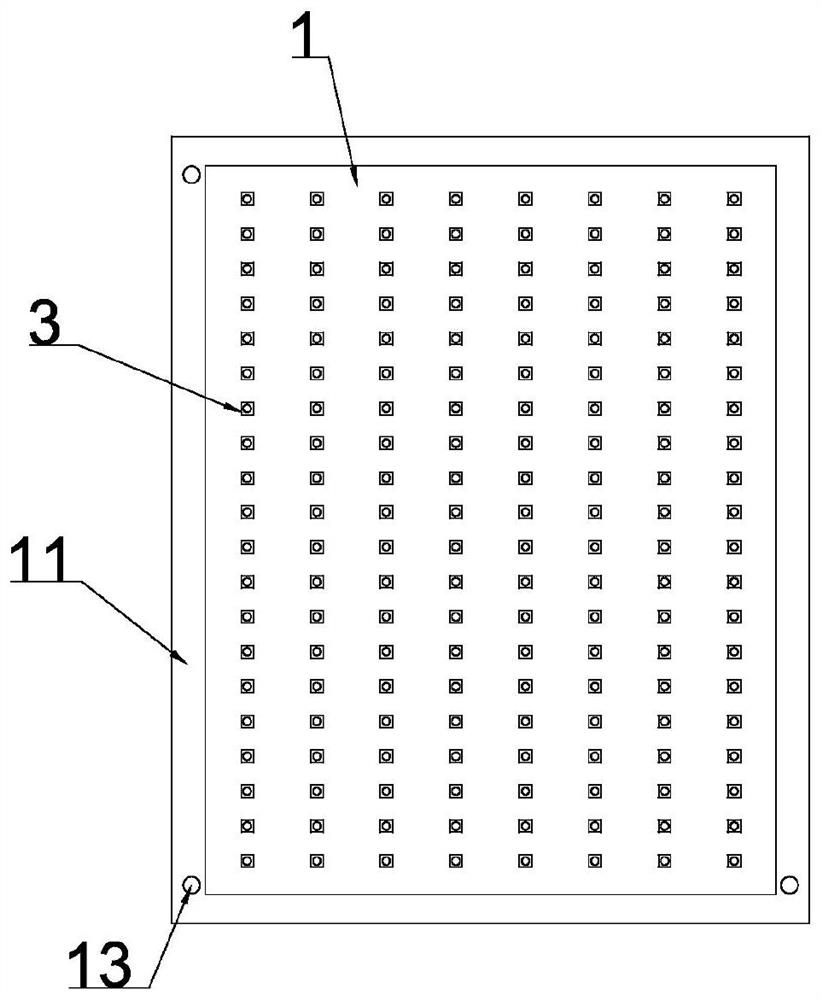

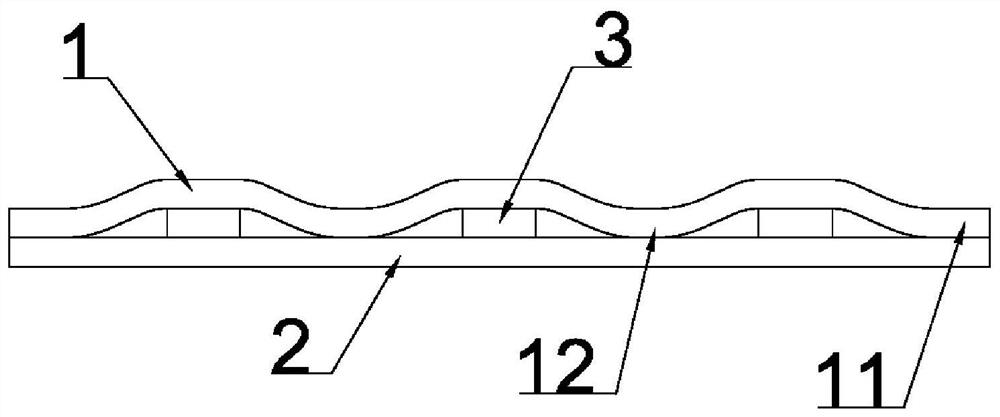

[0065] A dust-proof and sound-permeable membrane composite, comprising a release film with an adhesive layer on the surface and a dust-proof and sound-permeable membrane assembly, the release film includes a first release film and a second release film, and the dust-proof and sound-permeable membrane assembly One and only one side is sticky; the sticky side of the dust-proof sound-permeable film is bonded to the second release film, and the other side is bonded to the first release film;

[0066] The bonding strength between the dust-proof sound-permeable membrane assembly and the first release film is 40N / cm, and the bond strength between the dust-proof sound-permeable membrane assembly and the second release film is 14N / cm; the first release film The flexural strength of the film is 60MPa; the first adhesive area on the first release film is 4cm; the width of the second adhesive area is 1mm;

[0067] The thickness of the dust-proof sound-permeable membrane assembly is 80 μm,...

Embodiment 2

[0081] A dust-proof and sound-permeable membrane composite, comprising a release film with an adhesive layer on the surface and a dust-proof and sound-permeable membrane assembly, the release film includes a first release film and a second release film, and the dust-proof and sound-permeable membrane assembly One and only one side is sticky; the sticky side of the dust-proof sound-permeable film is bonded to the second release film, and the other side is bonded to the first release film;

[0082] The bonding strength between the dust-proof sound-permeable membrane assembly and the first release film is 50N / cm, and the bond strength between the dust-proof sound-permeable membrane assembly and the second release film is 20N / cm; the first release film The bending strength of the film is 80MPa; the first adhesive area on the first release film is 6cm; the width of the second adhesive area is 1.5mm;

[0083] The thickness of the dust-proof sound-permeable membrane assembly is 120 μ...

Embodiment 3

[0098] A dust-proof and sound-permeable membrane composite, comprising a release film with an adhesive layer on the surface and a dust-proof and sound-permeable membrane assembly, the release film includes a first release film and a second release film, and the dust-proof and sound-permeable membrane assembly One and only one side is sticky; the sticky side of the dust-proof sound-permeable film is bonded to the second release film, and the other side is bonded to the first release film;

[0099] The bonding strength between the dust-proof sound-permeable membrane assembly and the first release film is 30N / cm, and the bond strength between the dust-proof sound-permeable membrane assembly and the second release film is 8N / cm; the first release film The flexural strength of the film is 40MPa; the first adhesive area on the first release film is 3cm; the width of the second adhesive area is 0.5mm;

[0100] The thickness of the dust-proof sound-permeable membrane assembly is 45 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com