Oil pipeline defoaming valve

A pipeline and defoaming technology, which is applied in the petroleum industry, processing hydrocarbon oil, and only multi-stage series refining process treatment, etc., can solve the problems of affecting crude oil transportation, occupying volume, crude oil overflow, etc., and achieves easy maintenance and elimination The bubble equipment is simple and the effect of improving the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

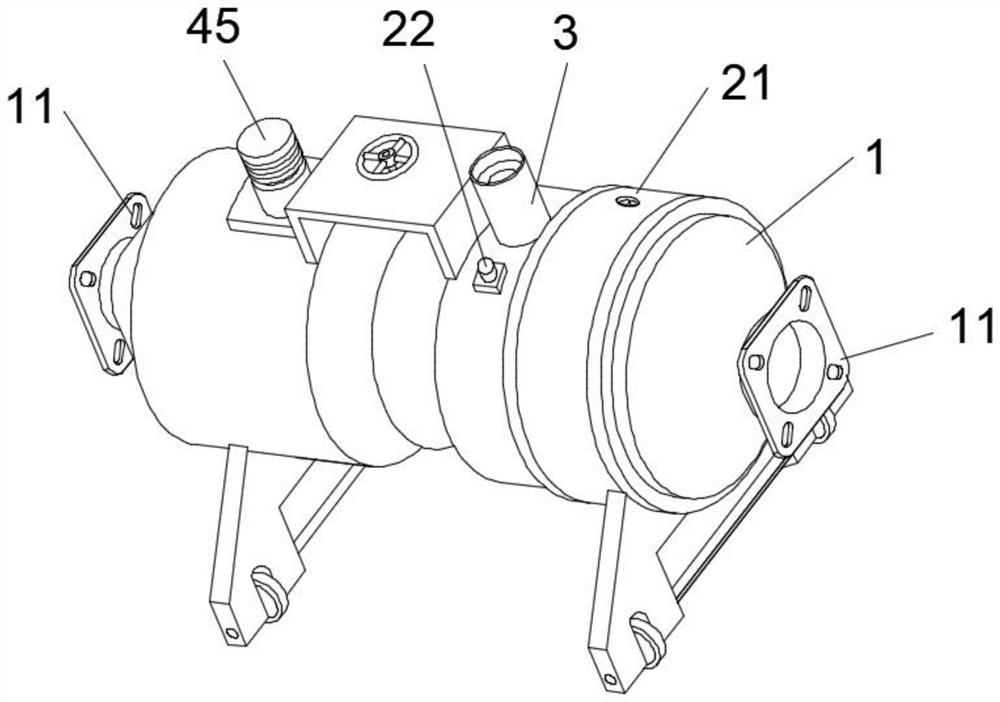

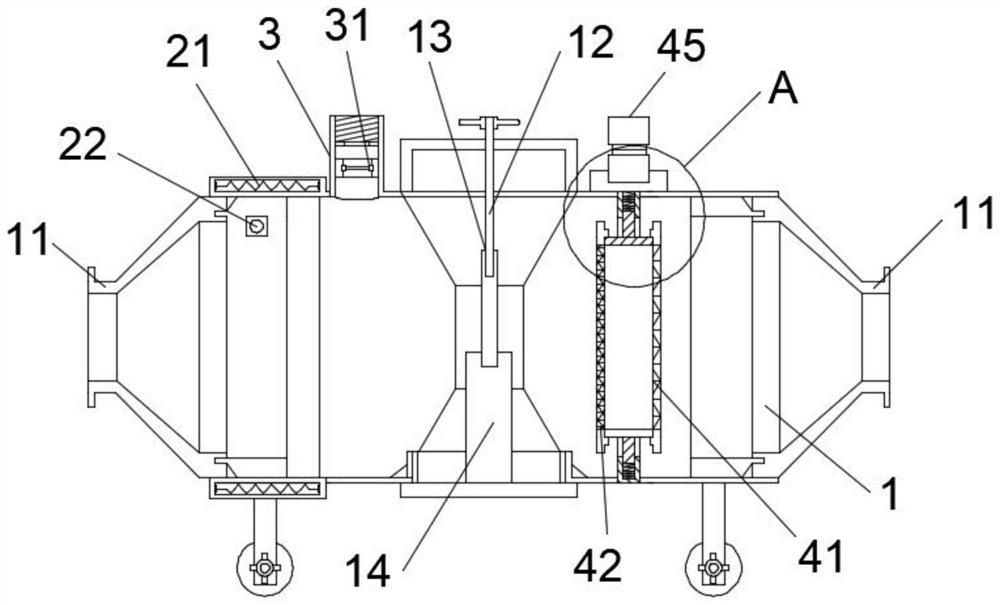

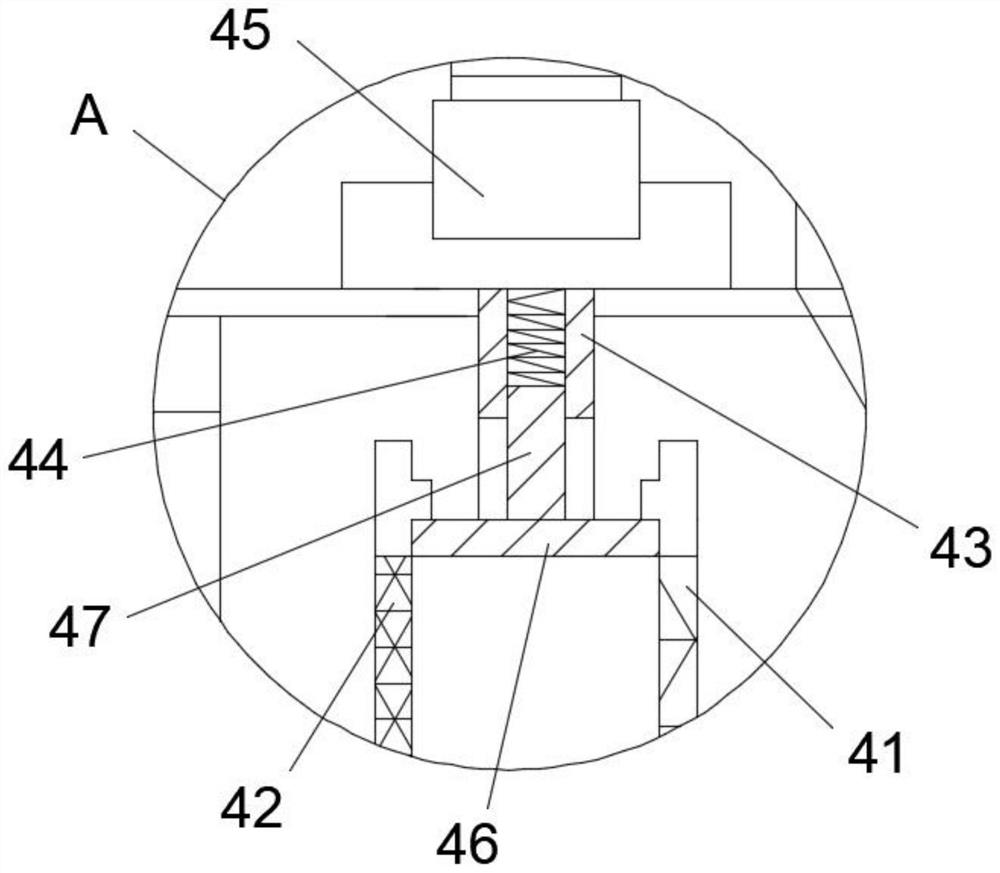

[0024] combine Figure 1-3 , an oil pipeline defoaming valve, including a valve body 1, a heat defoaming device, a dosing tube 3 and a vibrating defoaming device, the two sides of the valve body 1 are provided with connecting parts 11, and the inside of the valve body 1 A valve stem 12 is provided, the bottom end of the valve stem 12 is provided with a valve core 13, and the bottom of the valve body 1 is also provided with a valve seat 14 that cooperates with the valve core 13. The valve seat 14 is threadedly connected with the valve body 1 Removable, the thermal defoaming device includes a heating module 21, a temperature sensing module 22 and a polytetrafluoroethylene layer, the heating module 21 is installed on the left side of the valve body 1, and the temperature sensing module 22 is embedded installed on the surface of the valve body 1, the polytetrafluoroethylene layer is installed on the inner surface of the valve body 1, the dosing tube 3 is connected to the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com